A base for printers with various specifications that automatically fixes and adjusts the range of heat dissipation

A wide range of technology for printers, applied in printing devices, printing, etc., can solve the problems of reducing cooling effect, air pollution, single heat dissipation area, etc., and achieve the effects of avoiding dumping and breaking, high degree of automation, and increasing heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

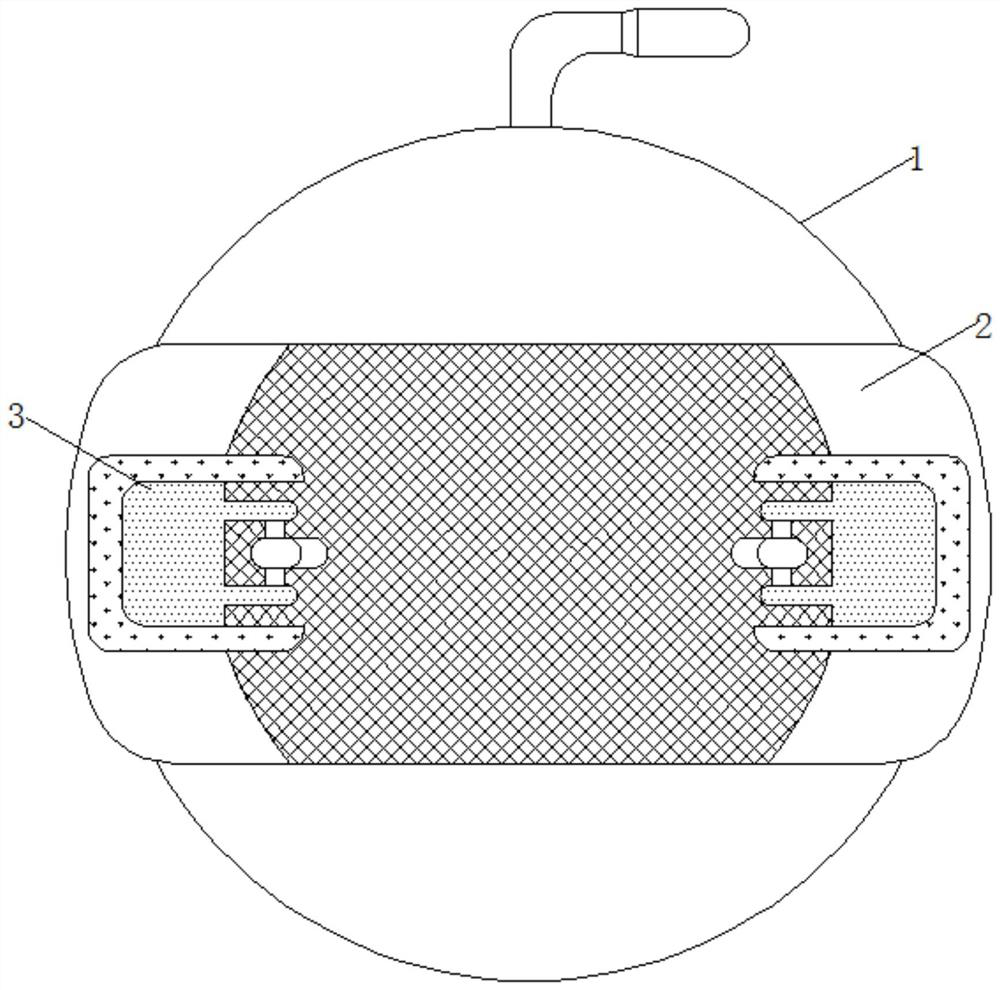

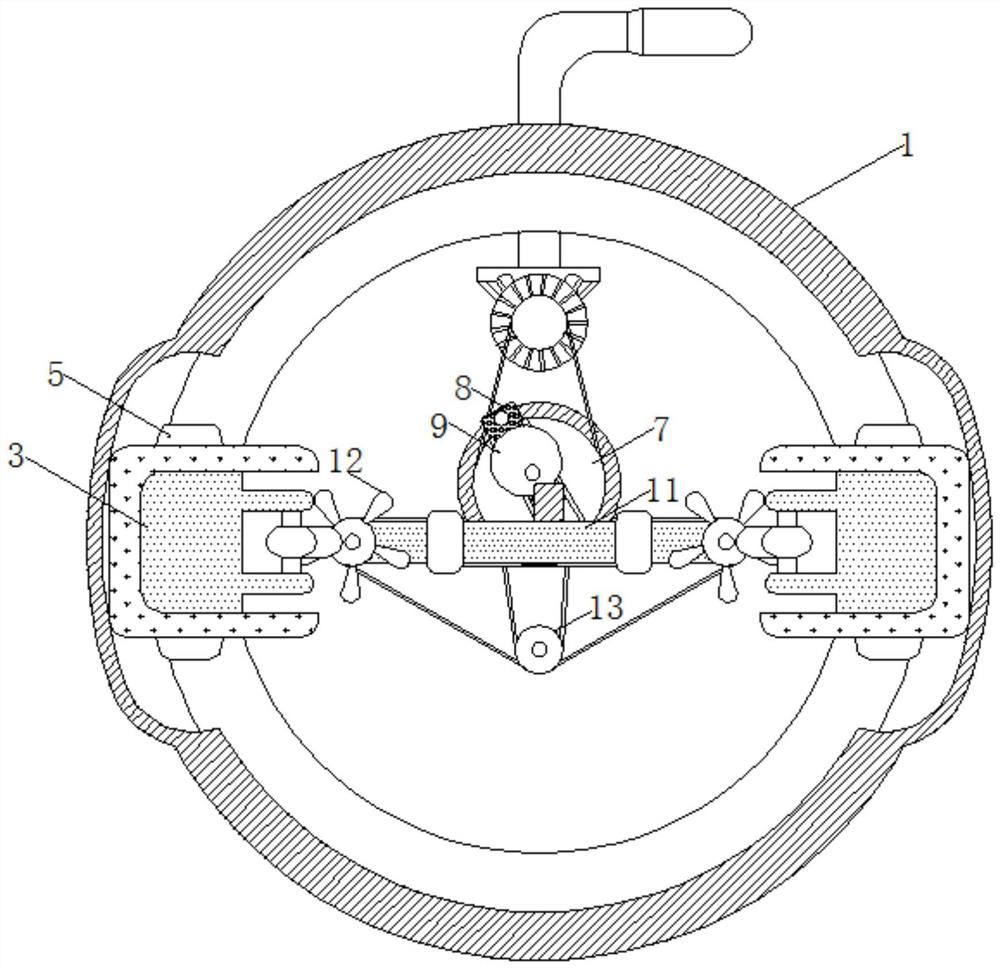

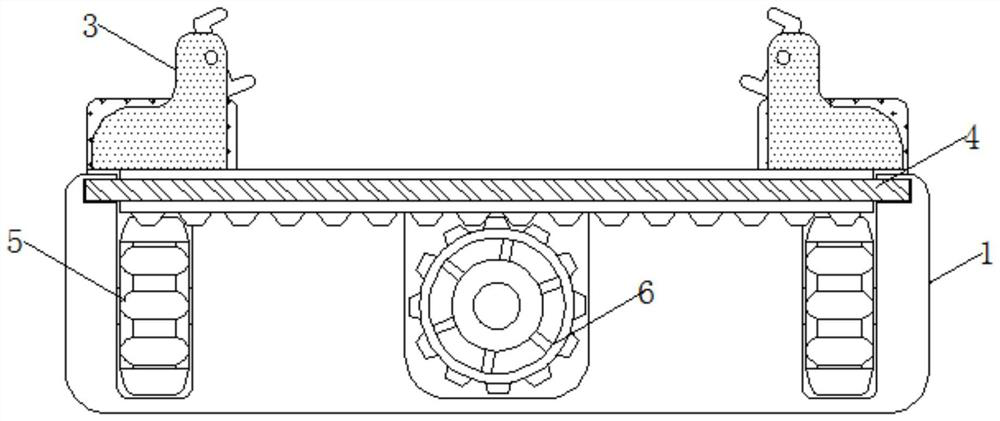

[0023] See Figure 1-5 An automatic fixation and adjusting the base of the scaling range, including the bottom frame 1, and the upper plate 1 is fixed to the bottom frame 1, and the surface of the upper plate 2 is opened, the top plate 2 is active. The card block 3 is connected, the card block 3 has two and the size is the same, and the central axis of the two card blocks 3 is referred to in the reference present symmetric distribution, and the bottom of the block 3 is opened, and the external active connection of the block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com