Die structure for secondary ejection of anti-sticking product

A secondary ejection and product technology, applied in the field of molds, can solve problems such as product surface damage and inability to guarantee product molding quality, and achieve the effects of no strain, accurate positioning, and complete mold opening and forming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

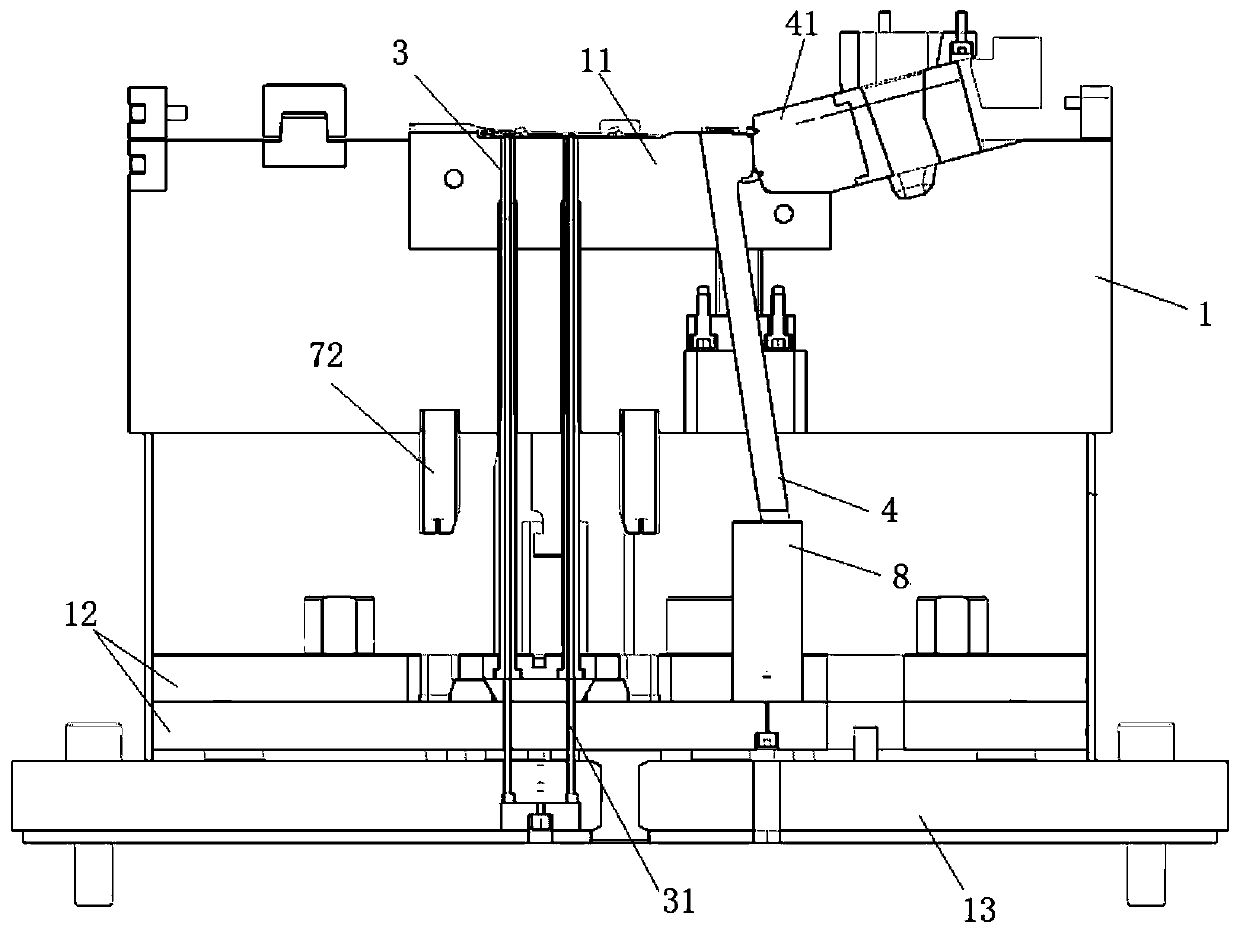

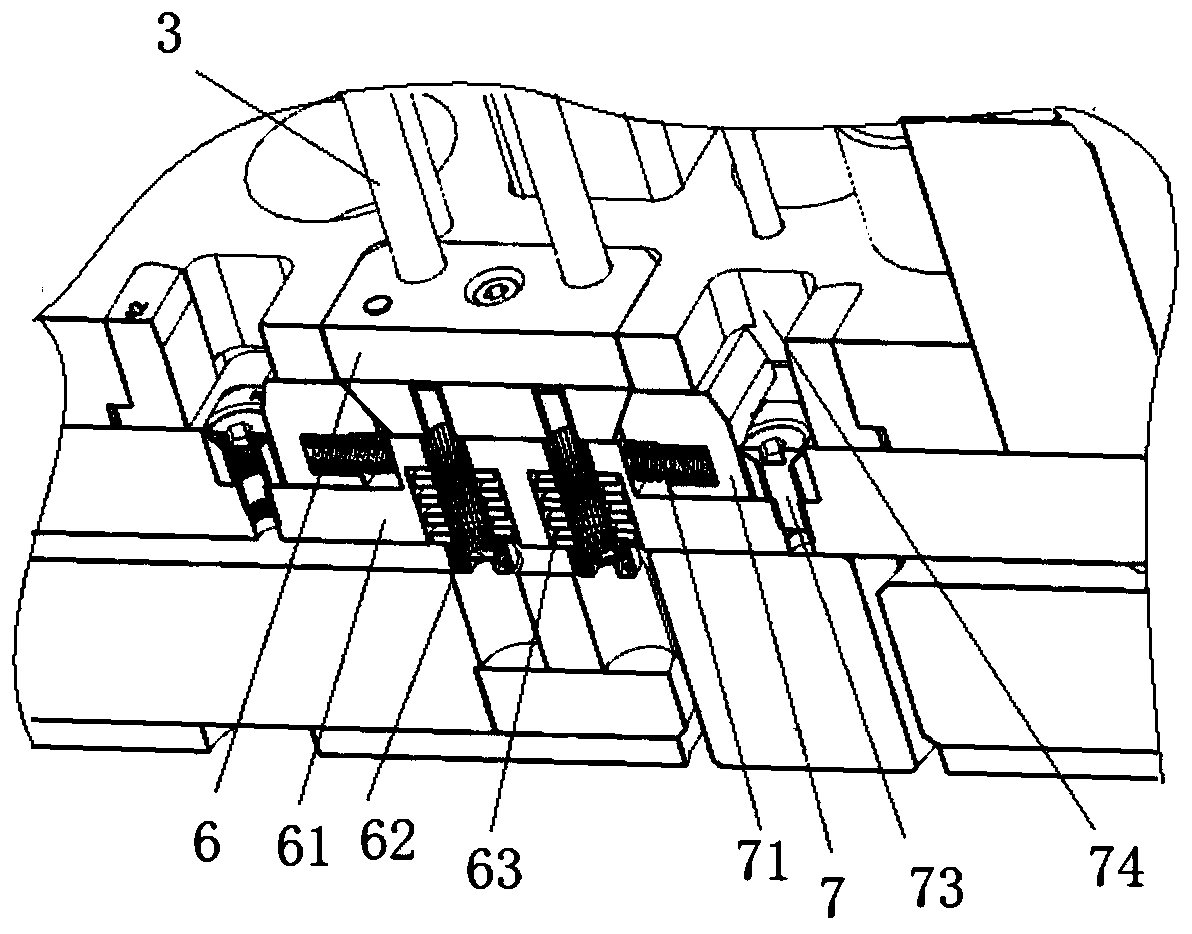

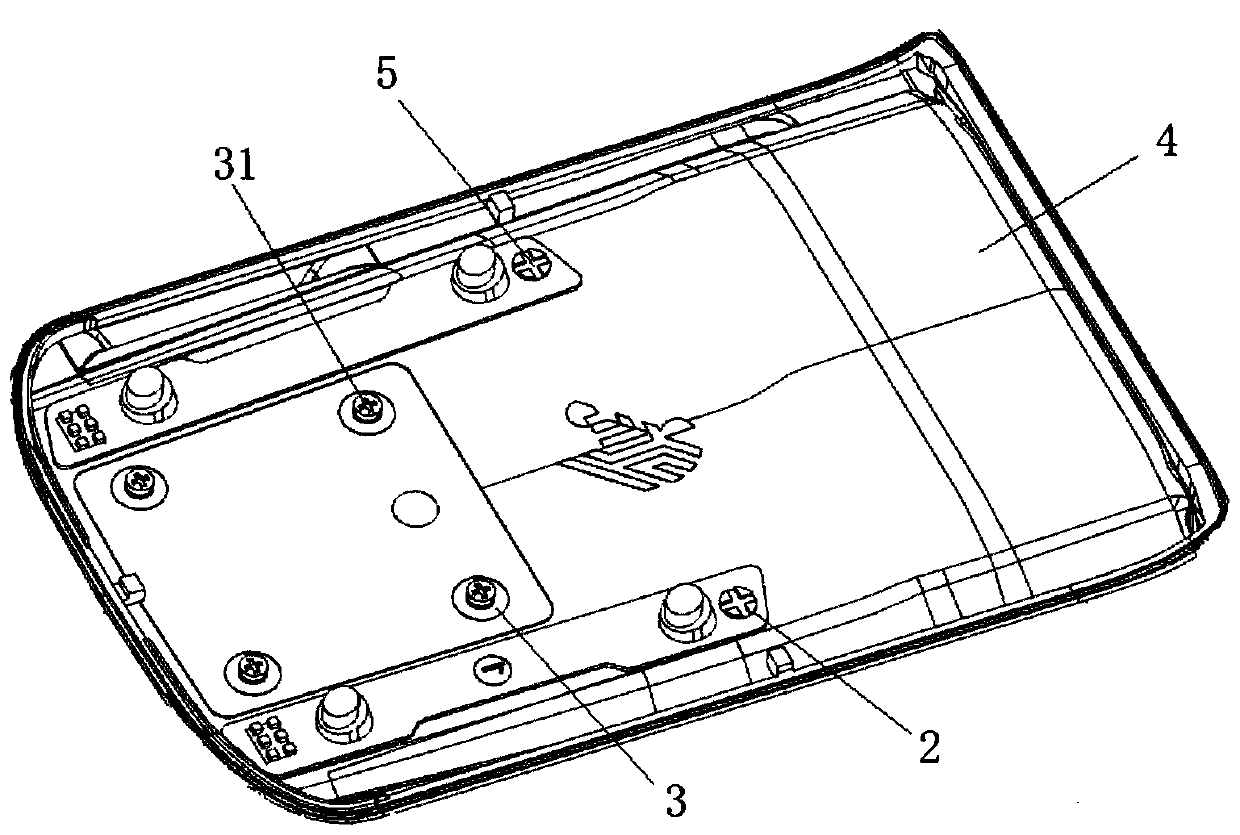

[0023] refer to Figure 1-3 As shown, this embodiment is a secondary ejection mold structure for anti-sticking products, including the lower mold core 11 embedded in the lower template 1, the ejector plate 12 arranged under the lower template 1, and the ejector plate 12 at the bottom of the ejector plate 12. Bottom plate 13, a number of thimbles 2 and a number of tubes 3 arranged on the ejector plate 12 and extending to the surface through the lower mold core 11, inclined rods 4 arranged on the ejector plate 12 and extending to the surface of the lower mold core 11, set on the bottom plate 13 and runs through the inner needle 31 of the cylinder 3; when the mold is opened, the product in the lower mold core 11 is absorbed by the manipulator (not shown in the figure), and the inner needle 31, thimble 2 and inclined rod 4 are pre-balanced to eject the product. The cylinder 3 is lifted higher than the surface of the inner needle 31 to eject the product twice, and the surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com