Surround members for stainless steel pipe cutting

A technology for pipe cutting and stainless steel, which is applied in the direction of pipe shearing devices, shearing devices, and attachments of shearing machines, etc., which can solve the problems of wasting pipe fitting materials, cutting end faces that are difficult to reach flat, and wasting time for operators, so as to avoid waste , high flatness and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

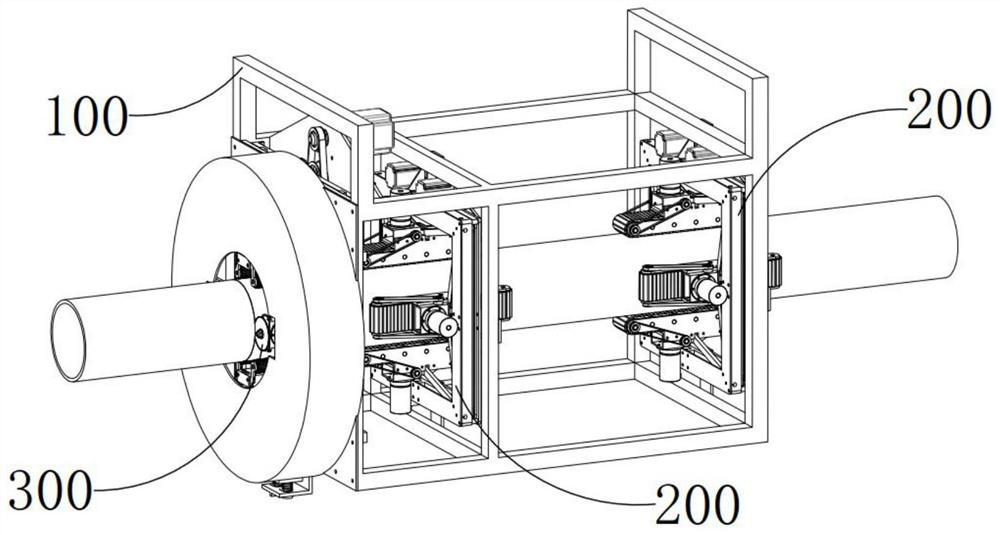

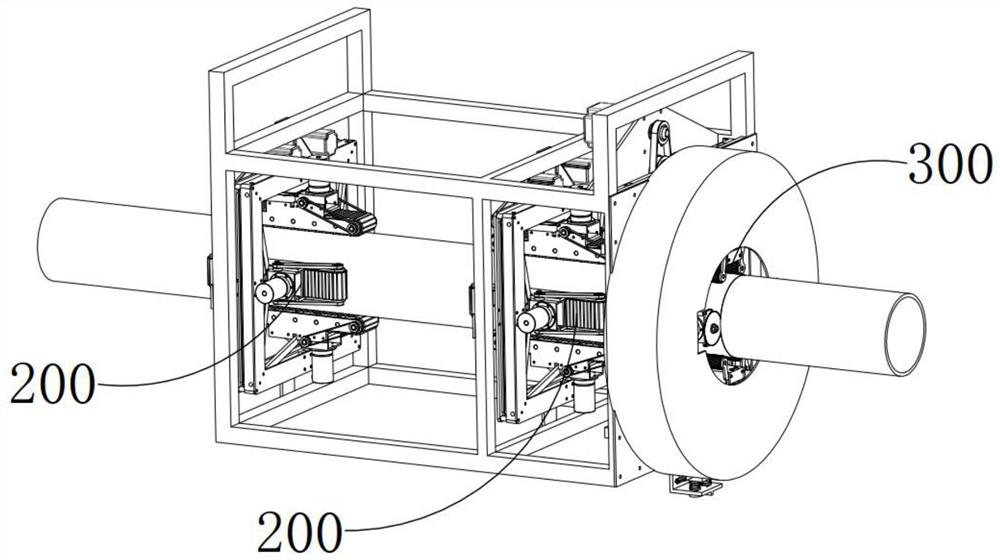

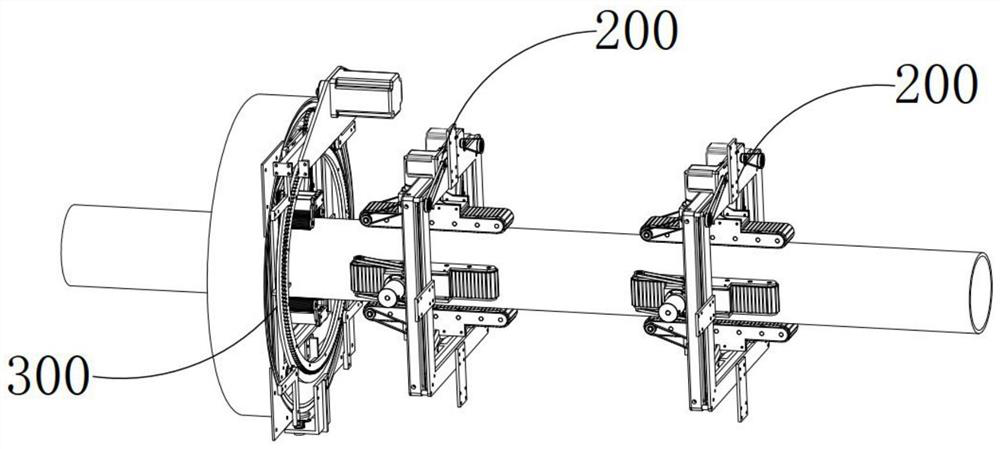

[0049] see Figure 1-26 , a double-saw surround pipe cutting machine, which includes a mounting frame 100, a clamping and feeding device 200, and a surrounding cutting device 300. There are two clamping and feeding devices 200 arranged front and rear and fixedly installed on the mounting frame 100. The surrounding cutting device 300 is also fixedly installed on the mounting frame 100 and one of the clamping and feeding devices 200 is located between the other clamping and feeding device 200 and the surrounding cutting device 300. The middle position of the clamping and feeding device 200 and the surrounding cutting device 300 can allow the tube Passing through, the clamping and feeding device 200 can guide and clamp the penetrating pipe and feed it towards the surrounding cutting device 300, and the surrounding cutting device 300 can cut the passing pipe. The clamping and feeding device 200 includes The clamping part 210 and the box-shaped driving part 220, the clamping part 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com