A robust and balanced design method for the structural dynamic characteristics of key components of complex equipment

A technology of component structure and dynamic characteristics, which is applied in the field of robust and balanced design of the dynamic characteristics of the key components of complex equipment, can solve problems such as the anti-vibration design of the structure of key components of complex equipment, and achieves accurate feasibility assessment and constraint robustness measurement results. Guaranteed effect of anti-vibration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

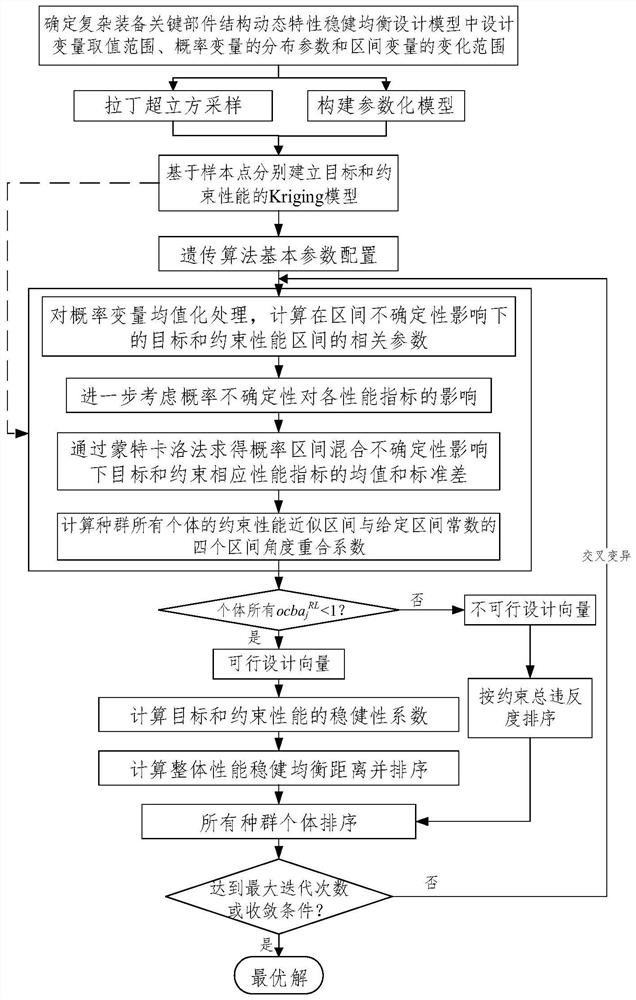

[0054] Using the robust and balanced design method for the dynamic characteristics of the key components of complex equipment proposed by the present invention, the anti-vibration design of the slider of a certain type of high-speed press is carried out, such as figure 1 As shown, the specific steps are as follows:

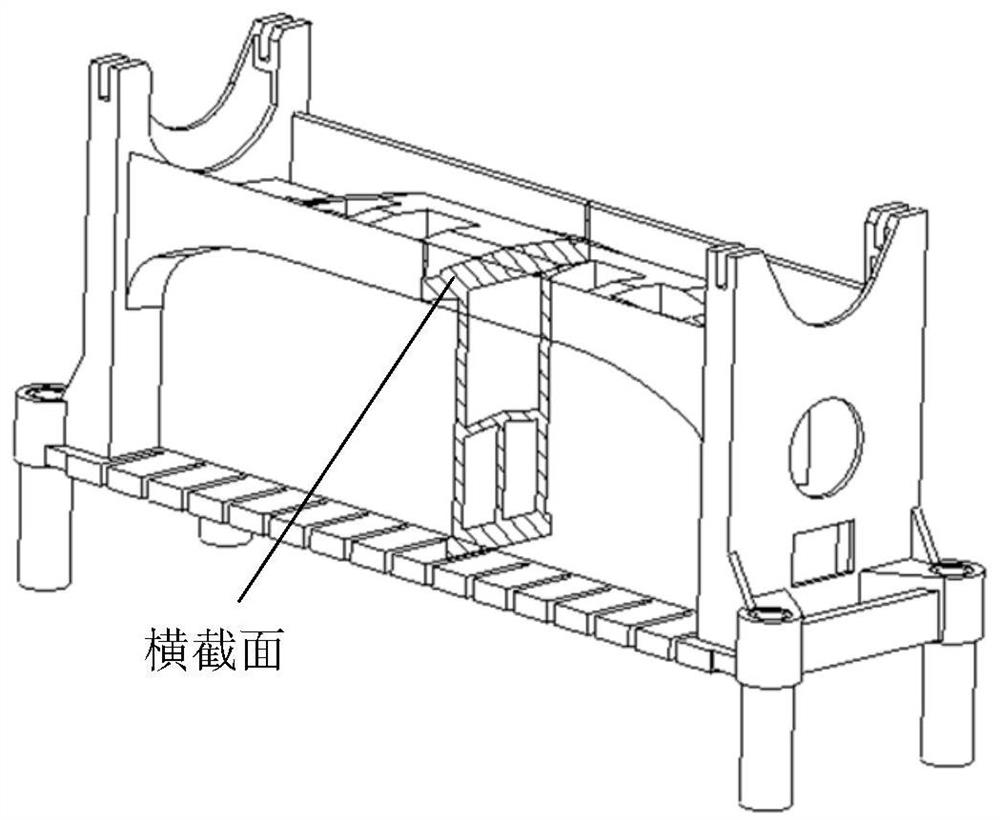

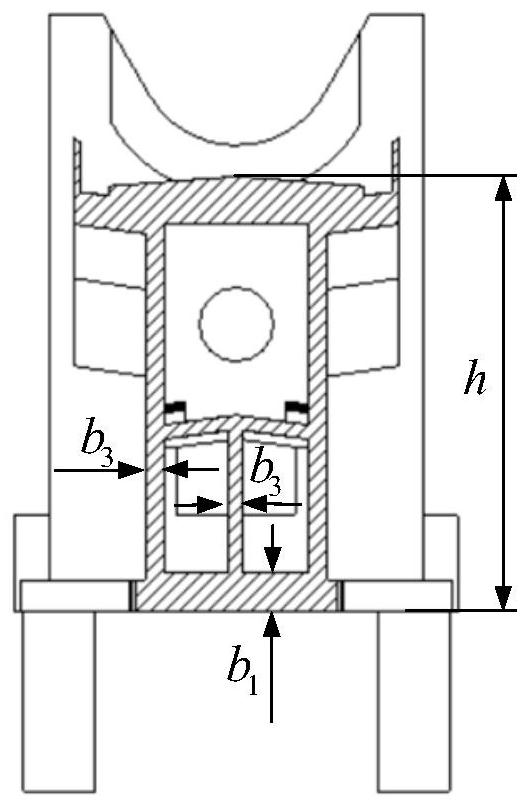

[0055] 1) Establish a robust and balanced design model for the dynamic characteristics of the high-speed press slider: figure 2 The slide block of the high-speed press shown is the design object, and the b in the slide block section is taken as 1 , b 2 , b 3 As design variables, considering the uncertainty of slider material Poisson's ratio v and density ρ, it is described as a probability variable, and considering the error of h in the process of processing, it is described as an interval variable. In the ideal proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com