Drying device for pottery fixed blank

A drying device and pottery technology, applied in drying, drying machine, heating device and other directions, can solve the problems of long time, unfavorable large-scale production, low production efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

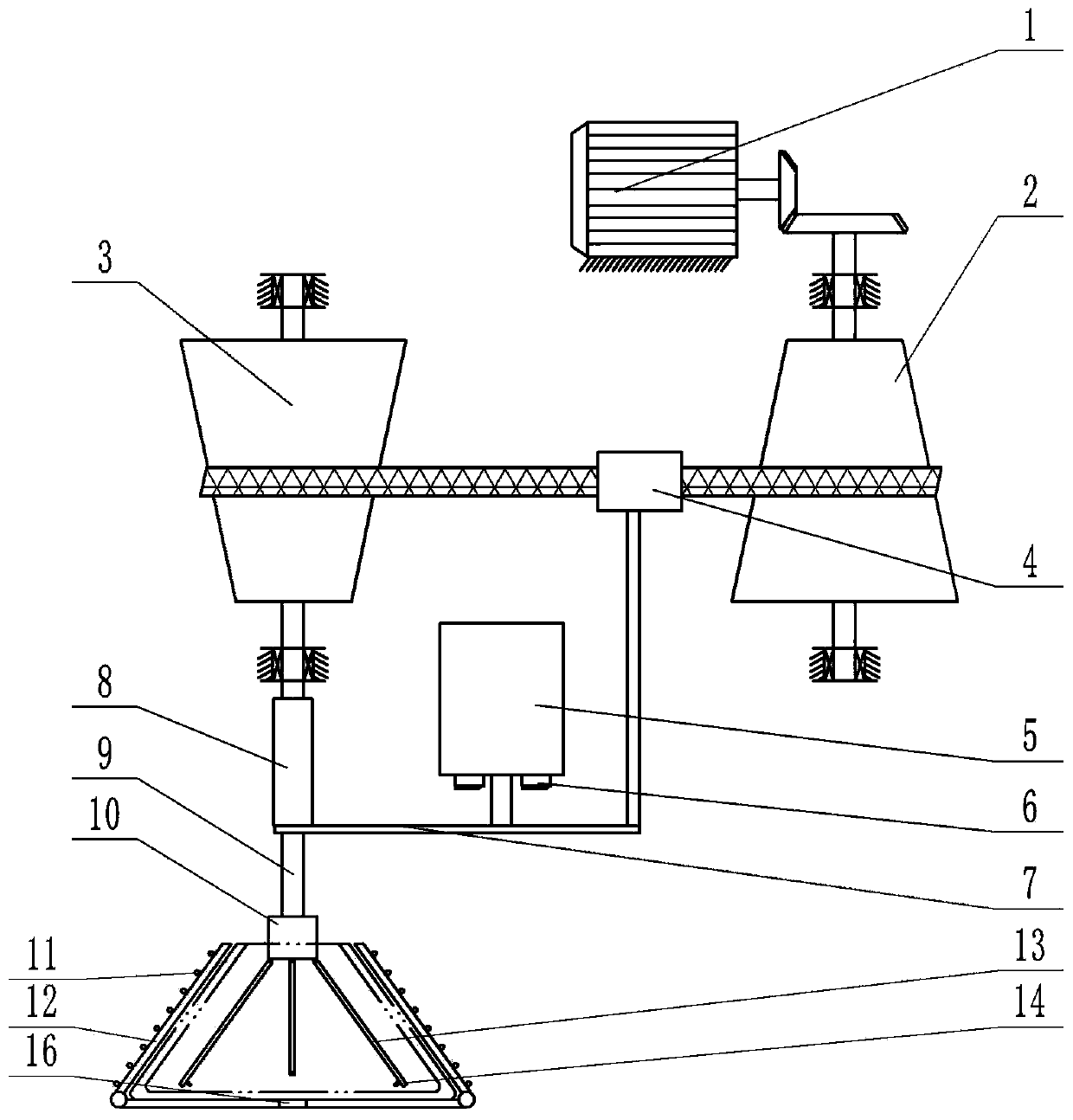

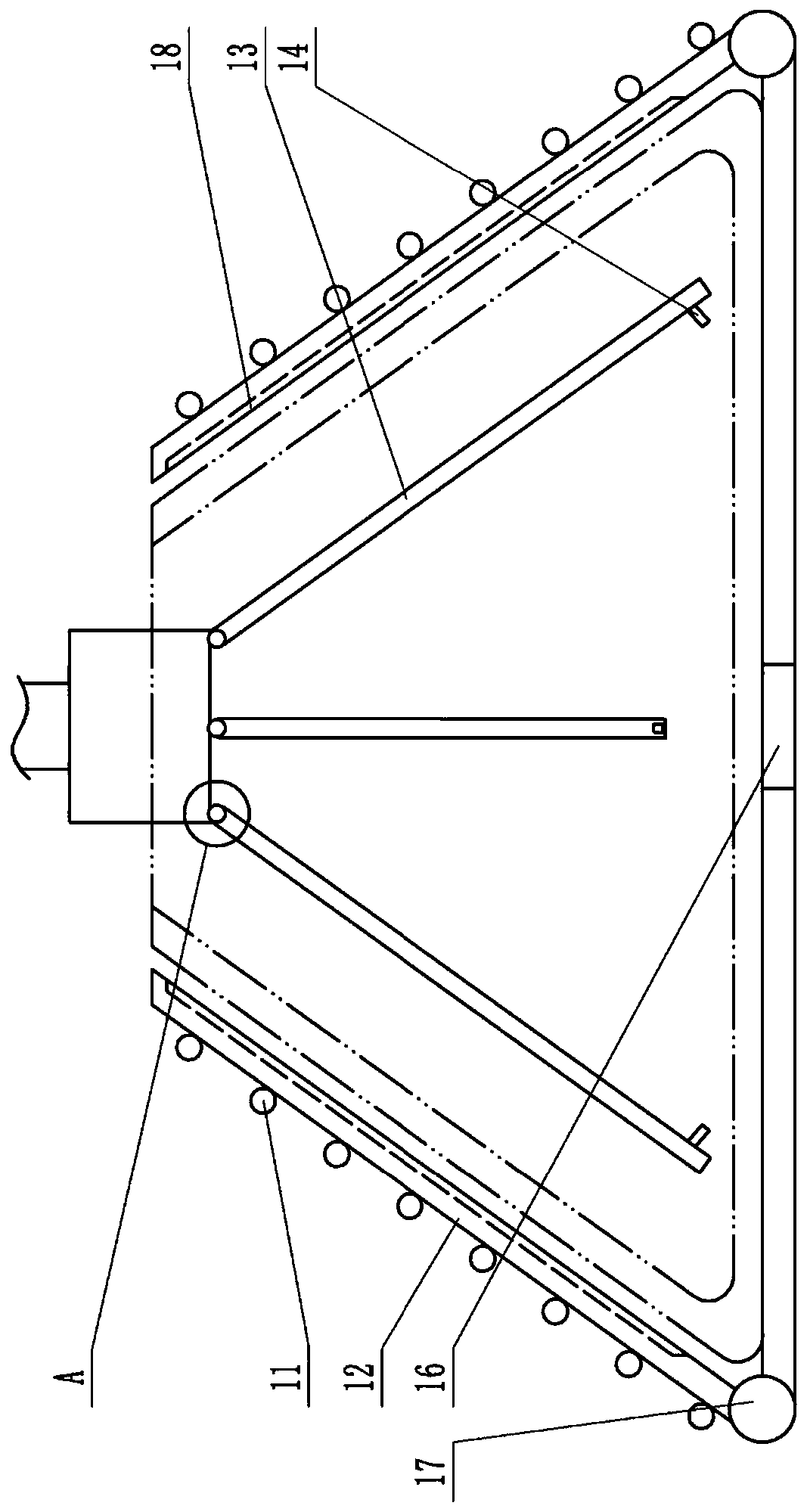

[0030] The utility model relates to a drying device for fixed embryos of pottery, which comprises a machine frame, a power part and a drying part under the power part.

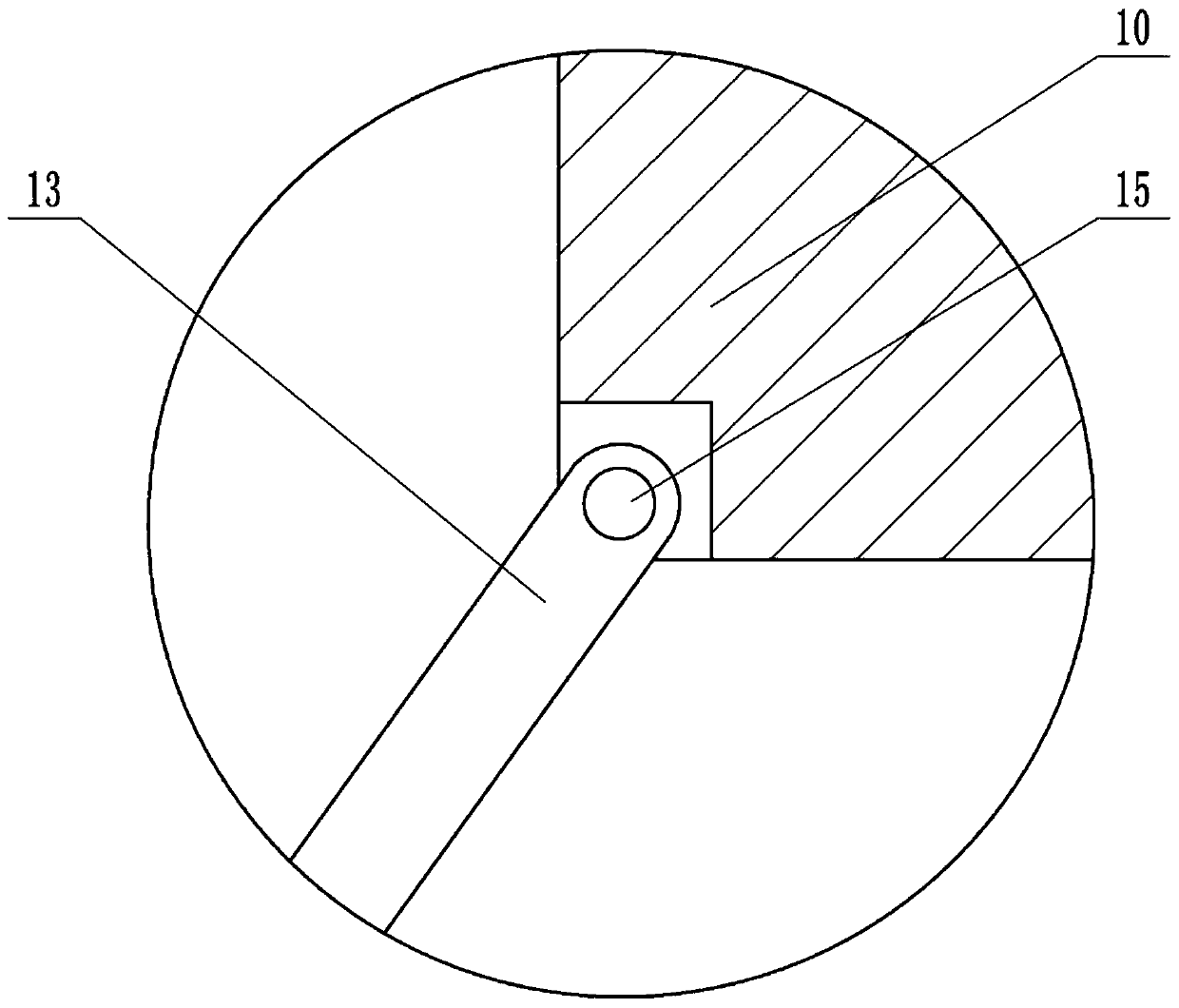

[0031] like figure 1 As shown, the power part includes a motor, a driving shaft, a driven shaft, a hydraulic cylinder 5, a shift fork 7, a connecting rod and a rotating shaft 9, wherein the motor is fixed on the frame, and the driving shaft and the driven shaft are vertically arranged and The two ends are rotatably connected to the frame through bearings. The middle part of the driving shaft is provided with an active tapered roller 2, and the middle part of the driven shaft is provided with a driven tapered roller 3, wherein the active tapered roller 2 is small at the top and large at the bottom (that is, the active cone The diameter of the driven tapered roller 2 gradually increases from top to bottom), the driven tapered roller 3 is large at the top and small at the bottom (that is, the diameter of the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com