High-strength polypropylene sectional material

A polypropylene profile, high-strength technology, used in building elements, connecting components, sheets/boards, etc., can solve the problems of the inability to adjust the width of the profile, the inability to apply to large-scale occasions, and the lack of strength, to increase the strength and connection. The effect of stability, compact structure and strong structural applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

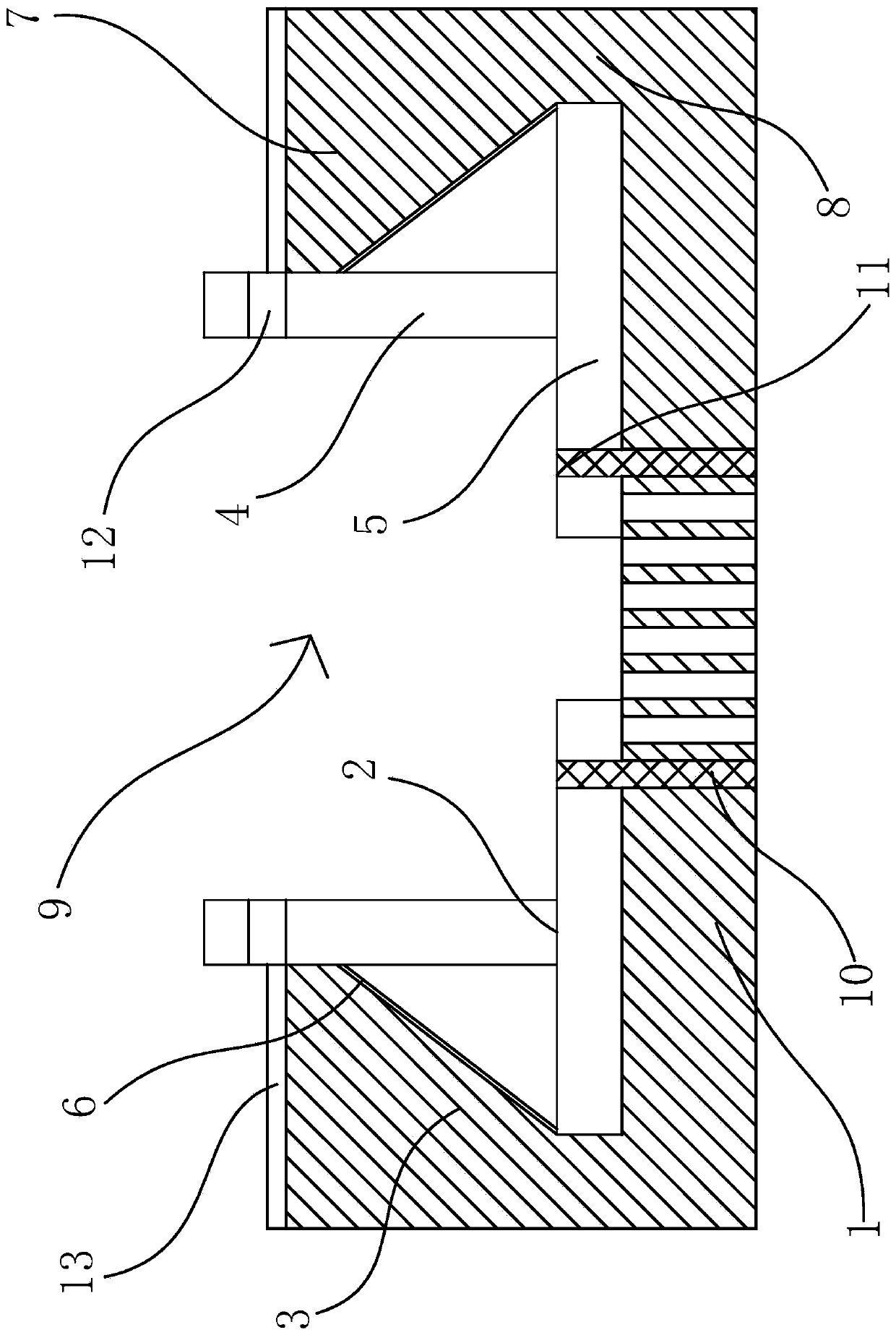

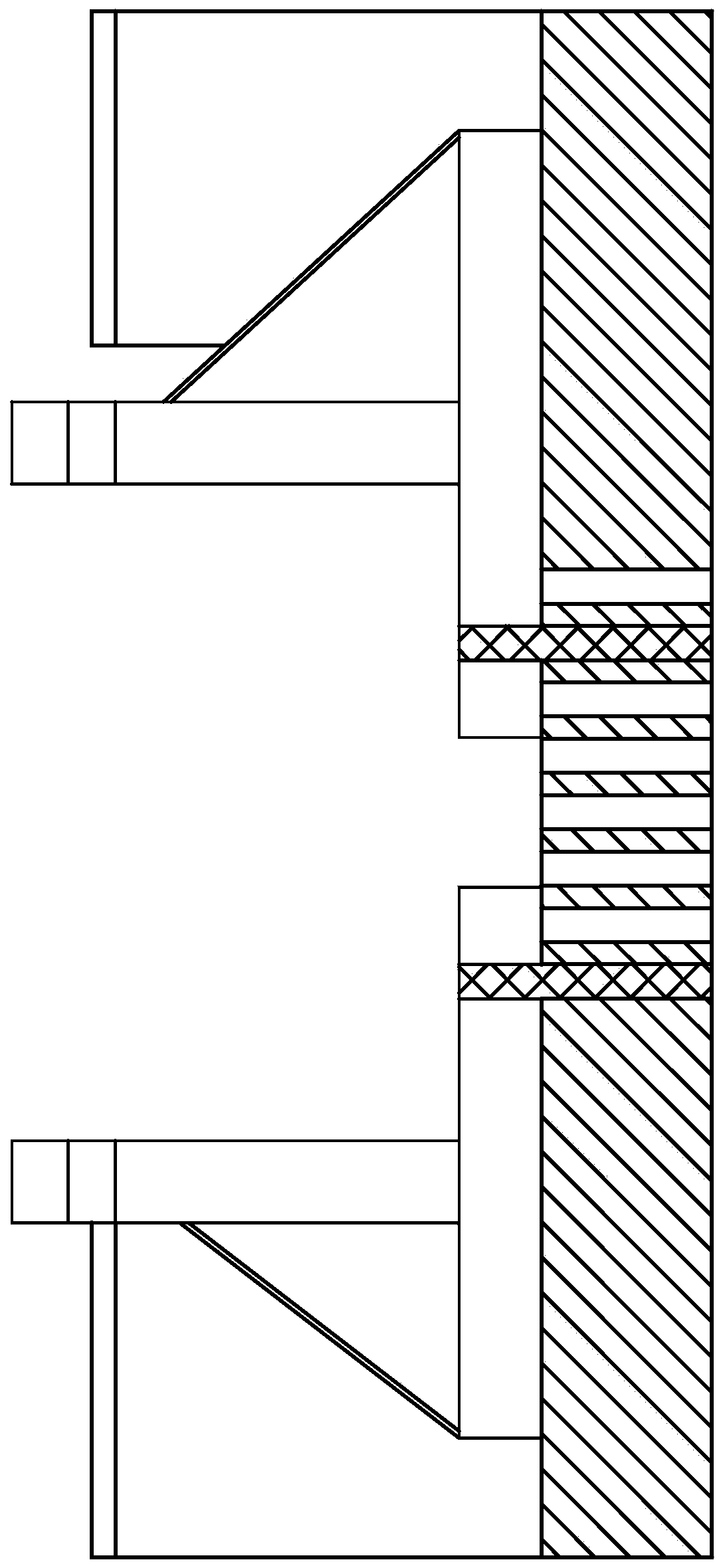

[0027] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the high-strength polypropylene profile includes a bottom plate 1, a connecting plate 2 and a fastening assembly 3, the above-mentioned bottom plate 1 is in the shape of a long plate, and the above-mentioned connecting plate 2 includes a plate-shaped body one 4 and a plate body two 5, The above-mentioned plate body one 4 is vertically connected to the middle part of the plate body two 5 and forms an inverted T-shaped connecting plate 2, there is a sheet-shaped reinforcing rib 6 between the above-mentioned plate body one 4 and the plate body two 5, and the bottom plate 1 is located at The lower part of the plate body 2 5 is in contact with the two surfaces, the upper part of the fastening assembly 3 is fastened to the reinforcing rib 6, and the lower part of the fastening assembly 3 is connected to the end of the bottom plate 1.

[0028] The fastening assembly 3 includes a plate-shaped plate body three 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com