Nut structure and special spanner thereof

A technology of nuts and nut sleeves, which is applied in the direction of nuts, wrenches, bolts, etc., which can solve problems such as troublesome installation process, damage to the cover, and potential safety hazards, and achieve the effects of convenient installation, high safety, and efficient assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

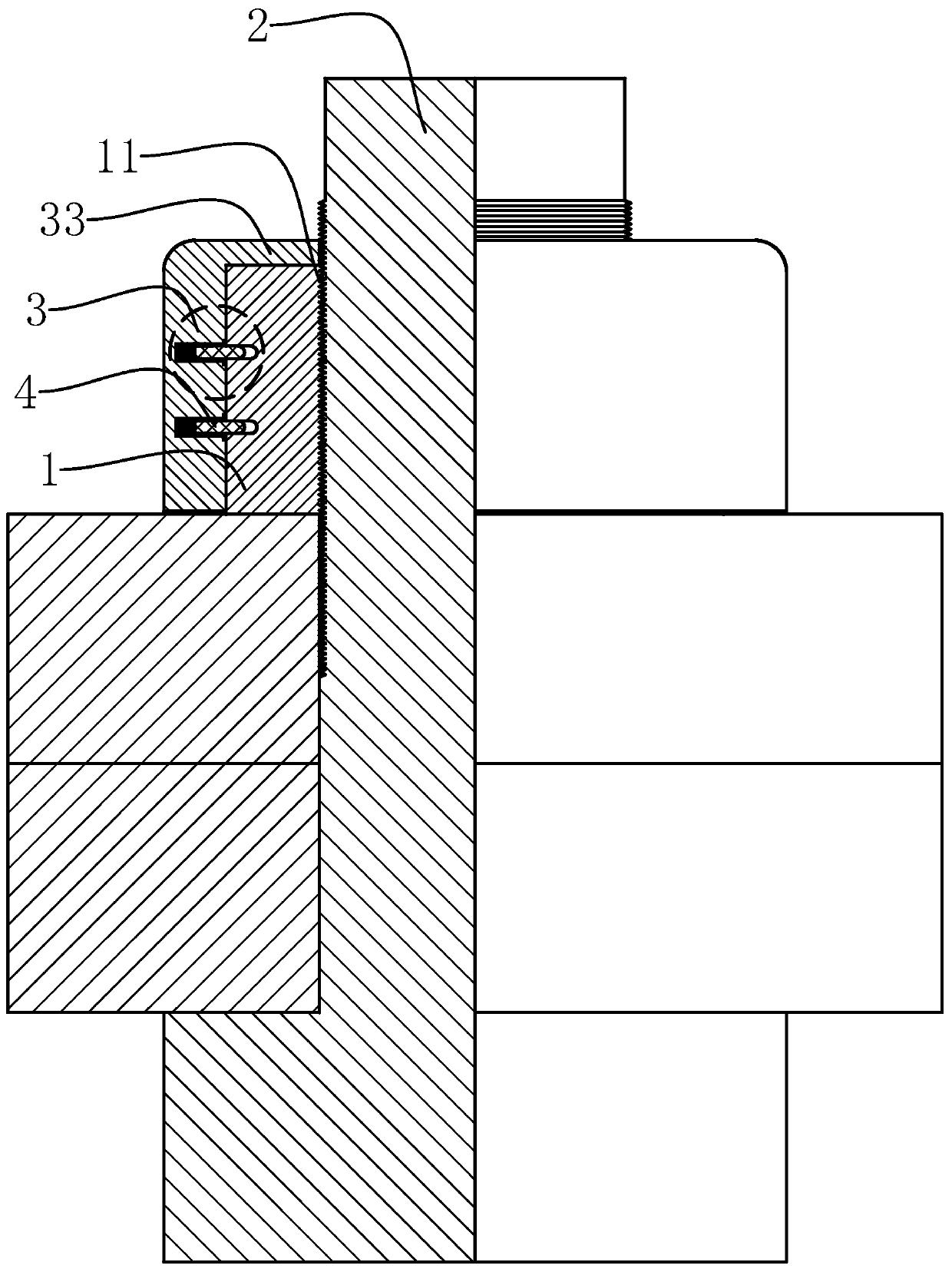

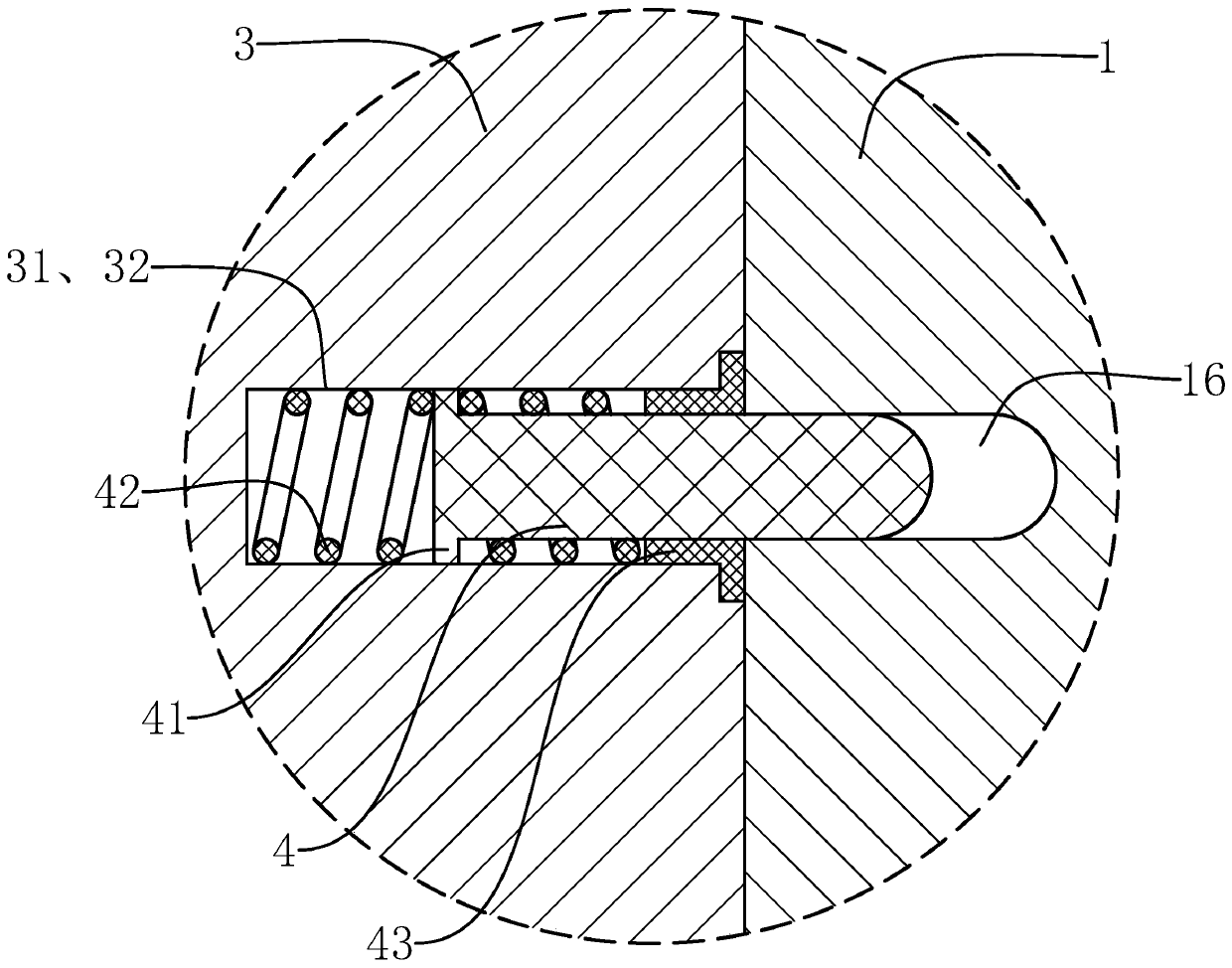

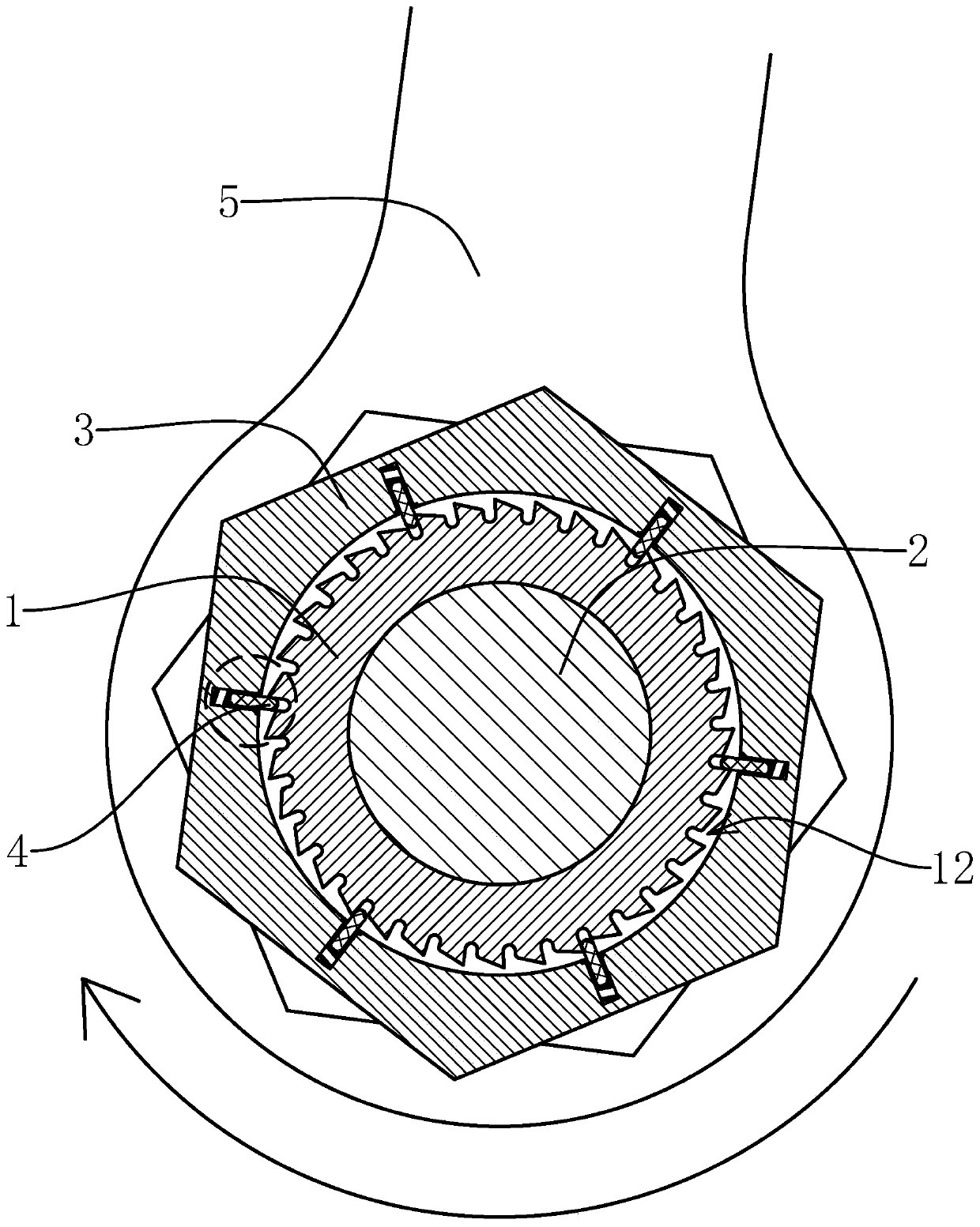

[0048] Such as Figure 1-8As shown, a nut structure of the present invention comprises a nut sleeve 1 with a threaded hole 11, and the nut sleeve 1 is screwed together with a bolt 2 with an external thread through the threaded hole 11. The outer wall of the nut sleeve 1 is a circular sleeve-like structure, and is connected with The threaded hole 11 is coaxial, and also includes an anti-theft cover 3 whose inner wall is a round hole. The outer wall of the anti-theft cover 3 is a regular hexagonal structure, and is coaxial with the inner wall of the anti-theft cover 3, and the anti-theft cover 3 is fitted on the nut cover 1;

[0049] An anti-theft mechanism is provided between the nut sleeve 1 and the anti-theft sleeve 3. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com