Energy-saving type efficient insulating aluminum alloy door-window unit

A kind of aluminum alloy doors and windows, energy-saving technology, applied in the direction of windows/doors, window/door frames, building components, etc., can solve the problems of untreated structural thermal insulation, affecting the thermal insulation effect of window structures, etc. The effect of tightness and strong sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

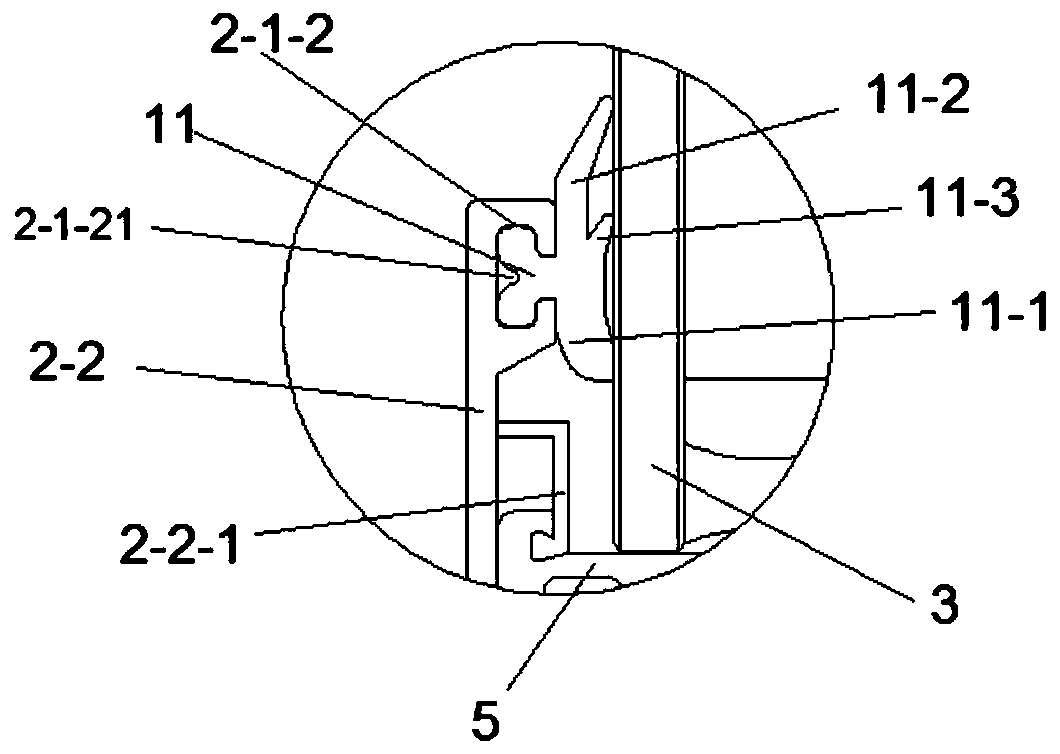

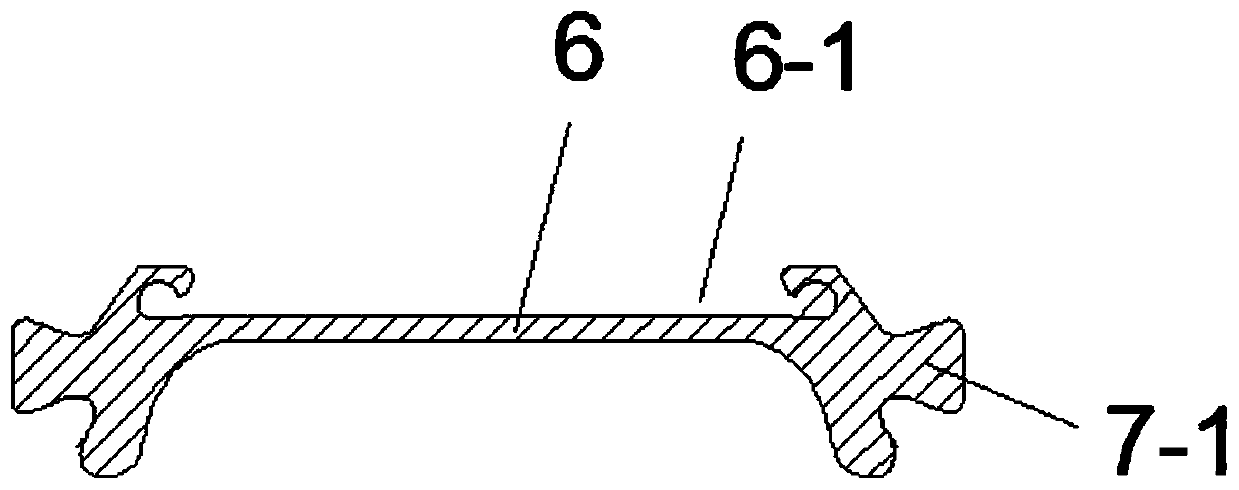

[0055] combined with Figure 1-4 It can be seen that an energy-saving high-efficiency thermal insulation aluminum alloy door and window includes a window frame profile 1, a sash profile 2, a glass 3, a bead 4, and a glass insulation strip 5; the window frame profile 1 includes an inner frame profile 1-1 and an outer frame profile 1 -2, the connection between the inner frame profile 1-1 and the outer frame profile 1-2 is realized through the window frame inner heat insulation strip 6 and the window frame outer heat insulation strip 7; the window sash profile 2 includes the inner sash profile 2-1 and The outer fan profile 2-2, the inner fan profile 2-1 and the outer fan profile 2-2 are connected through the sash inner heat insulation strip 8 and the window sash outer heat insulation strip 9; the top surface of the inner fan profile 2-1 One side has a groove-like structure, forming a mounting groove 2-1-1;

[0056] The top side of the window frame profile 1 is provided with a ga...

Embodiment 2

[0071] combined with Figure 1-5 It can be seen that the difference between Embodiment 2 and Embodiment 1 is that the top side of the outer frame profile 1-2 and the top of the inner wall are provided with a third fixed leg 2-2-2, and the third fixed leg 2-2-2 At the same time, it is arranged on both sides of the top surface of the inner frame profile 1-1; the top surface of the outer frame profile 1-2 is provided with an outer frame heat insulation strip 14, and the cross section of the outer frame heat insulation strip 14 is "L" shaped structure, the heat insulation bar block 7-1 is set on the top and bottom of the outer frame heat insulation strip 14 at the same time, and the outer frame heat insulation strip 14 is attached to the top surface of the outer frame profile 1-2, The heat-insulating bar clamping blocks 7-1 are respectively embedded in the third fixed feet 2-2-2 on the outer frame profile 1-2, so that the outer frame heat-insulating bar 14 is locked with the outer...

Embodiment 3

[0073] combined with Figure 5 , 6 It can be seen that the difference between embodiment 3 and embodiment 2 lies in the heat insulation strip 8 and the gap sealing strip 10 in the sash, and one end of the heat insulation strip 8 in the sash is provided with a side block 8-1 of the heat insulation strip in the sash. One end of the inner heat insulation strip side block 8-1 of the window sash is embedded in the inner fan profile 2-1 to realize fixing, the inner heat insulation strip side block 8-1 of the window sash, the inner heat insulation strip 8 of the window sash and the inner fan profile 2-1 It is a groove structure, forming the installation groove 2-1-1; the bottom end of the heat insulation strip 8 in the sash forms two air chamber structures; the length of the spacer sealing strip in embodiment 3 is longer than that in embodiment 1 There are three gap sealing sheets 10 - 1 arranged on the gap sealing strip 10 for the length of the sealing strip, arranged in an oblique...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com