Method for preparing high-purity aluminum nitride spherical powder through plasma reaction atomization

A plasma and spherical powder technology, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of poor spheroidization rate, average purity of aluminum nitride powder, and no refined production steps, etc. The effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

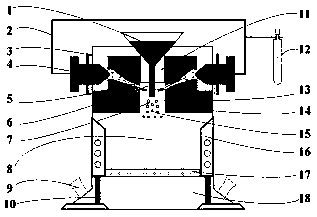

[0045] This embodiment is a specific structure of a device for preparing high-purity aluminum nitride spherical powder by plasma reaction atomization. figure 1 As shown, the molten aluminum 1 enters the reaction atomization chamber 13 through the aluminum liquid transportation channel 11; the nitrogen gas source 12 delivers nitrogen gas to the plasma torch 4 through the transportation pipeline 2, and the plasma torch 4 is connected to the reaction atomization chamber 13 through the flange 3 , the generated nitrogen plasma achieves supersonic speed in the flow channel of the reaction atomization nozzle 14, and is ejected at the annular seam outlet 6, forming a 360-degree annular supersonic nitrogen plasma beam 5; The atomization chamber 13 is impacted and atomized into aluminum droplets 6, and at the same time, the aluminum droplets 7 react with the nitrogen plasma to form aluminum nitride 15; the aluminum nitride 15 leaves the reaction atomization chamber 13 and falls into the ...

Embodiment 2

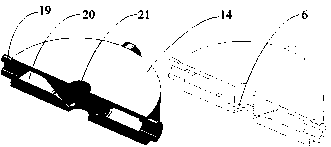

[0047] This embodiment is a specific structure of the reactive atomizing nozzle 14 in Embodiment 1. Depend on figure 2 As shown in the non-transparent sectional view (left) and transparent sectional view (right) of the nozzle, nitrogen plasma enters the supersonic flow channel 20 through the inlet 19, the supersonic flow channel 20 is a compression-expansion structure, and the nitrogen plasma is in The supersonic flow channel 20 accelerates to supersonic speed and disperses into a 360-degree full-coverage plasma beam, which is finally sprayed from the annular slot outlet 6 into the central hole of the reaction atomization nozzle to form an atomization focus.

Embodiment 3

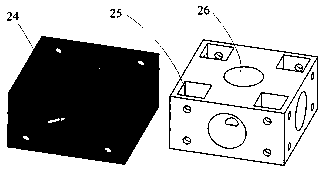

[0049] This embodiment is another specific structural schematic diagram of the reactive atomizing nozzle in embodiment 1, and its structure is similar to that of embodiment 2, the difference is that:

[0050] The structure is a multi-outlet reactive atomizing nozzle. The impact atomization effect of the multi-outlet reactive atomizing nozzle is worse than that of the annular slot outlet type, but the flow field is more stable than that of the annular slot type nozzle. Such as Figure 3-a , as shown in 3-b and 3-c, the specific structure has 4 entrances and 8 exits, of which Figure 3-a It is the axonometric view and perspective view of the structural appearance of the reaction atomizing nozzle, Figure 3-b It is a top view and a perspective view of the structure of the reaction atomizing nozzle, Figure 3-c It is a front view and a perspective view of the reaction atomizing nozzle structure. The reaction atomization nozzle structure is fixed to the reaction atomization cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com