Fluidization device for powder tank-type container

A fluidization device and container technology, applied in the field of powder material transportation equipment, can solve the problems of not being able to fully utilize the space in the tank and not being able to obtain transportation efficiency, so as to improve the unloading efficiency, increase the effective volume, and increase the fluidization area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this embodiment of the application:

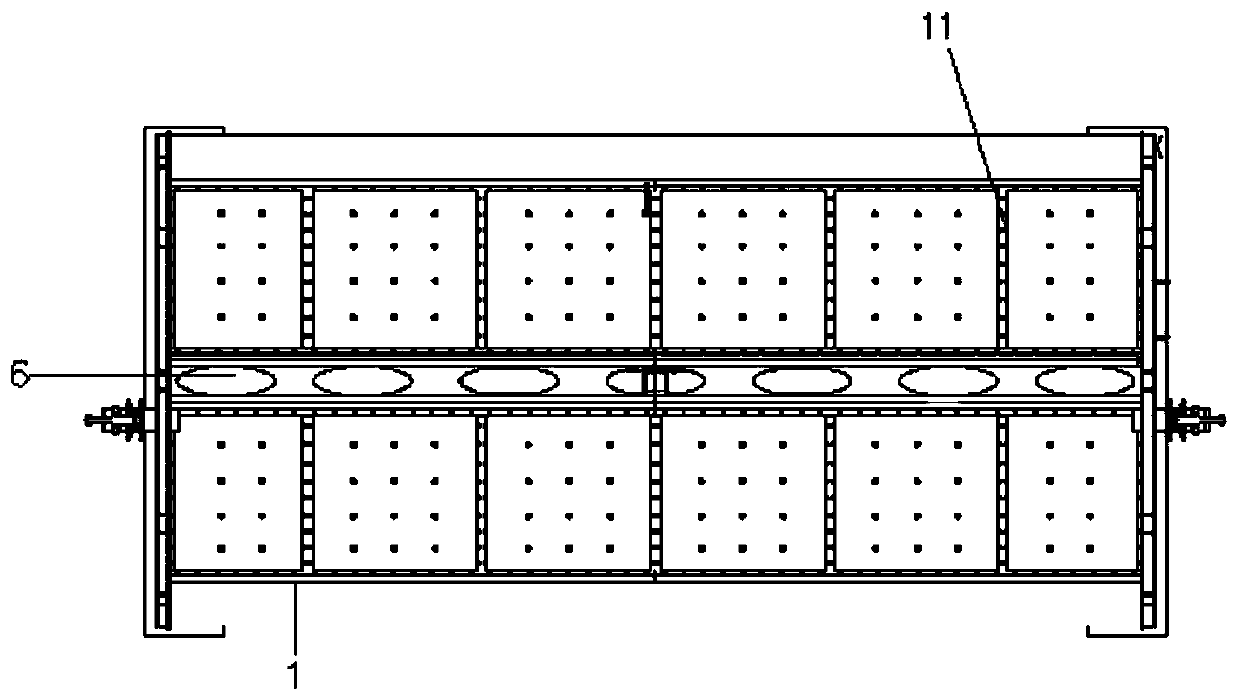

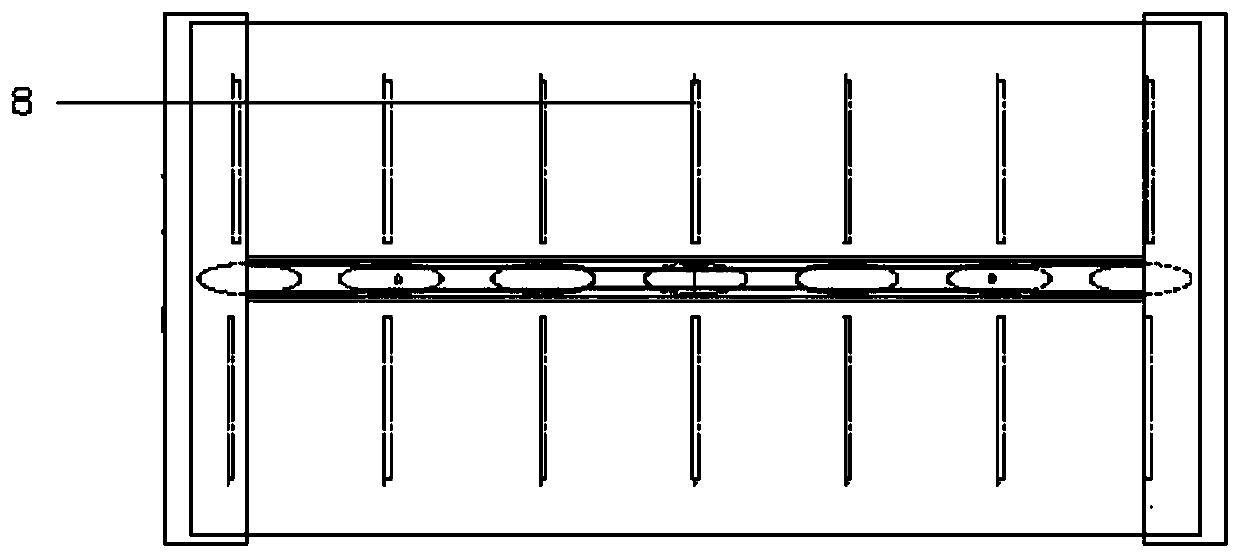

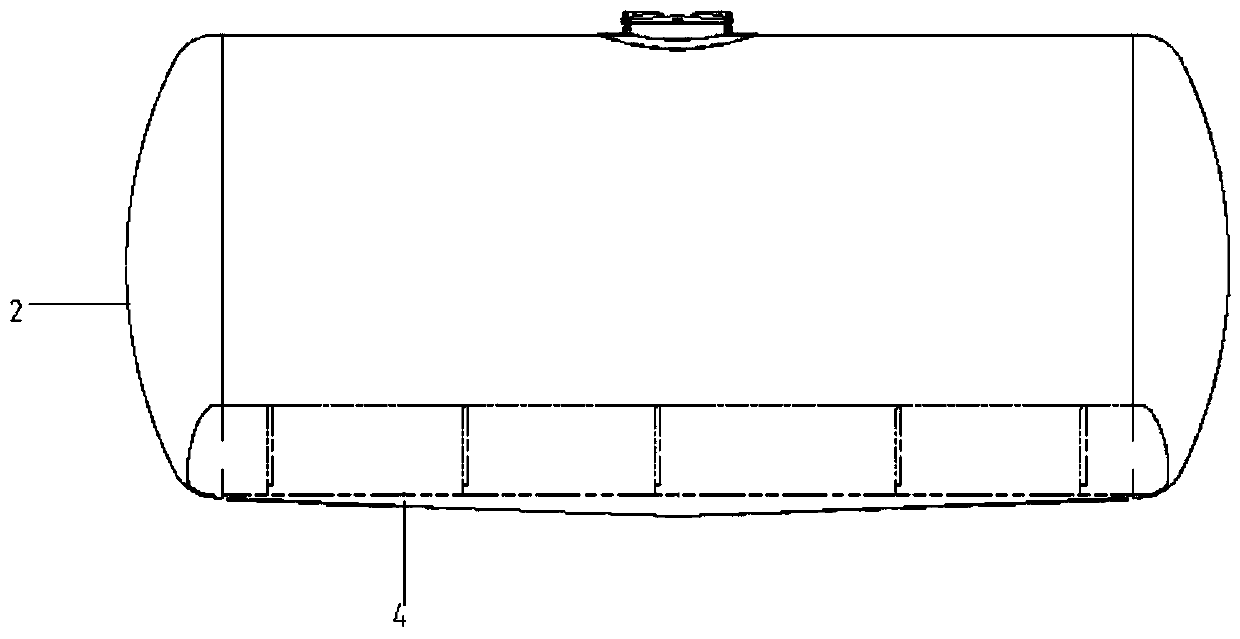

[0038] Such as Figure 1-5 As shown, a fluidization device for a powder tank container includes: a cylinder body 1, a head at both ends of the cylinder body 1, two sets of left and right fluidized beds 3, and a fluidized bed 3 below There is a longitudinal guide fluid 4, the fluidized bed 3 extends longitudinally along the cylinder 1, the fluidized bed 3 is arranged inside the cylinder 1, between the fluidized bed 3 and the cylinder 1 The air chamber structure 5 is formed. The left and right sets of fluidized beds 3 are inclined structures, the upper end of the fluidized bed 3 is connected to the side of the cylinder 1, and the lower end of the fluidized bed 3 is connected to the bottom of the cylinder.

[0039] In this embodiment, the left and right two sets of fluidized beds 3 have the effects of fluidization and diversion at the same time.

[0040] Furthermore, the fluidized bed 3 has an inclined arc structure, the maximum vertical...

Embodiment 2

[0050] In this embodiment of the application:

[0051] Such as Figure 1-2 , Image 6 , Figure 7 As shown, a fluidization device for a powder tank container includes: a cylinder body 1, a head at both ends of the cylinder body 1, two sets of left and right fluidized beds 3, and a longitudinal guide fluid is arranged below the fluidized bed 3 4. The fluidized bed 3 extends longitudinally along the cylinder 1. The fluidized bed 3 is arranged inside the cylinder 1. An air chamber structure 5 is formed between the fluidized bed 3 and the cylinder 1, and the upper end of the fluidized bed 3 is connected to the cylinder 1. side.

[0052] The fluidized bed 3 includes a porous plate 9, a gas-permeable layer 10, and a compression device 11. The gas-permeable layer 10 is laid on the porous plate 9, and the gas-permeable layer 10 is fixed on the porous plate 9 by the compression device 11. Fasteners are fixed.

[0053] The difference from Example 1 is that the fluidized bed 3 has an incline...

Embodiment 3

[0062] In this embodiment of the application:

[0063] Such as Figure 1-5 As shown, a fluidization device for a powder tank container includes: a cylinder body 1, a head provided at both ends of the cylinder body 1, two sets of left and right fluidized beds 3, and a longitudinal guide fluid below the fluidized bed 3 4. The fluidized bed 3 extends longitudinally along the cylinder 1. The fluidized bed 3 is arranged inside the cylinder 1. An air chamber structure 5 is formed between the fluidized bed 3 and the cylinder 1, and the upper end of the fluidized bed 3 is connected to the cylinder 1. On the side, the lower end of the fluidized bed 3 is connected to the bottom of the cylinder.

[0064] Further, the fluidized bed 3 has an inclined arc structure, the maximum vertical distance between the fluidized bed 3 and the cylinder 1 is 50 cm, and the included angle between the fluidized bed 3 and the cylinder 1 is 22.5°.

[0065] Furthermore, the bottom of the cylinder 1 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com