Recycled concrete waste recovery device

A recycled concrete and waste recycling technology, applied in grain processing, etc., can solve the problems of no screening structure, crushing precision adjustment, waste waste, etc., achieve crushing efficiency and quality improvement, crushing precision, and improve recycling quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

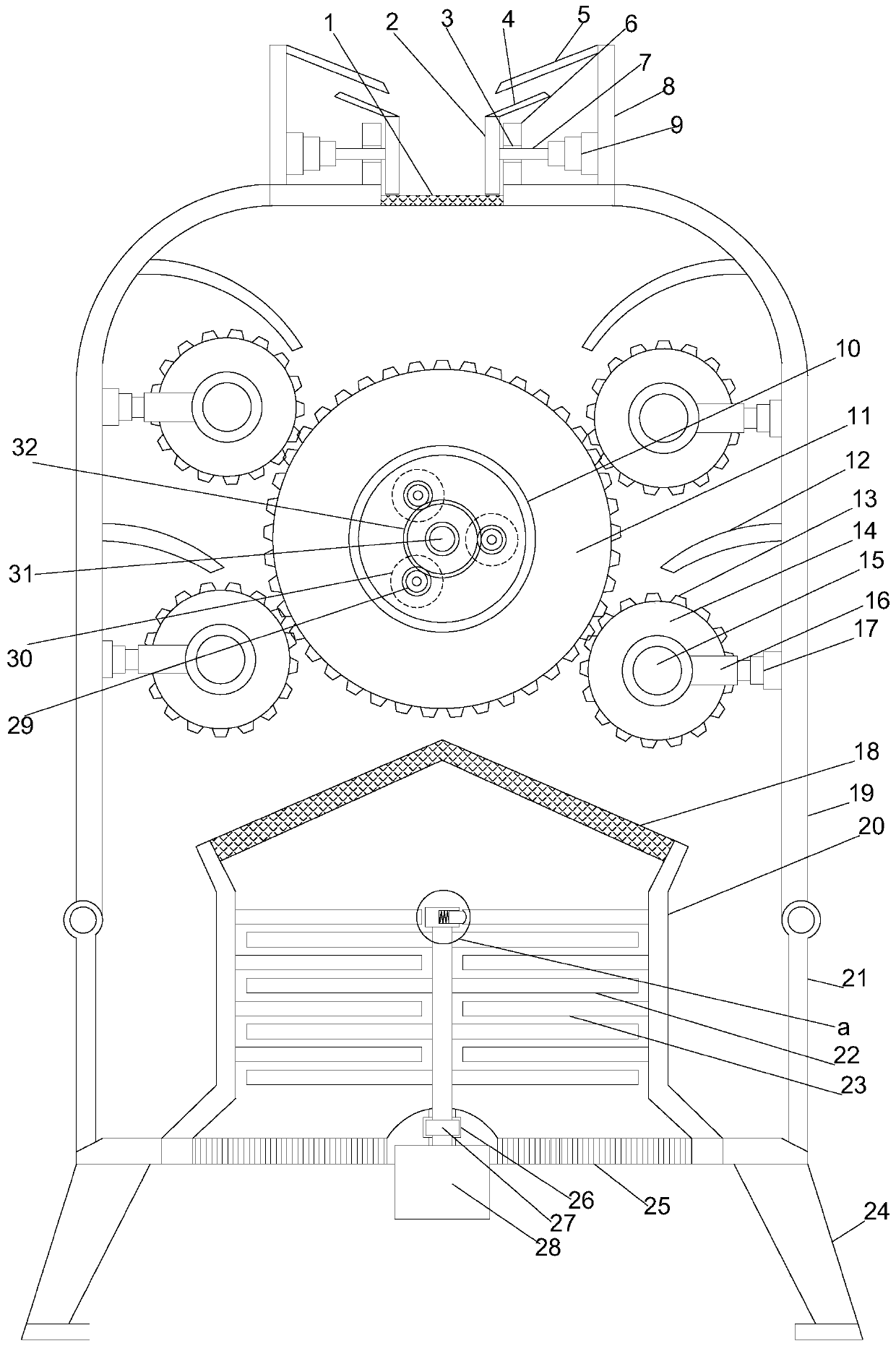

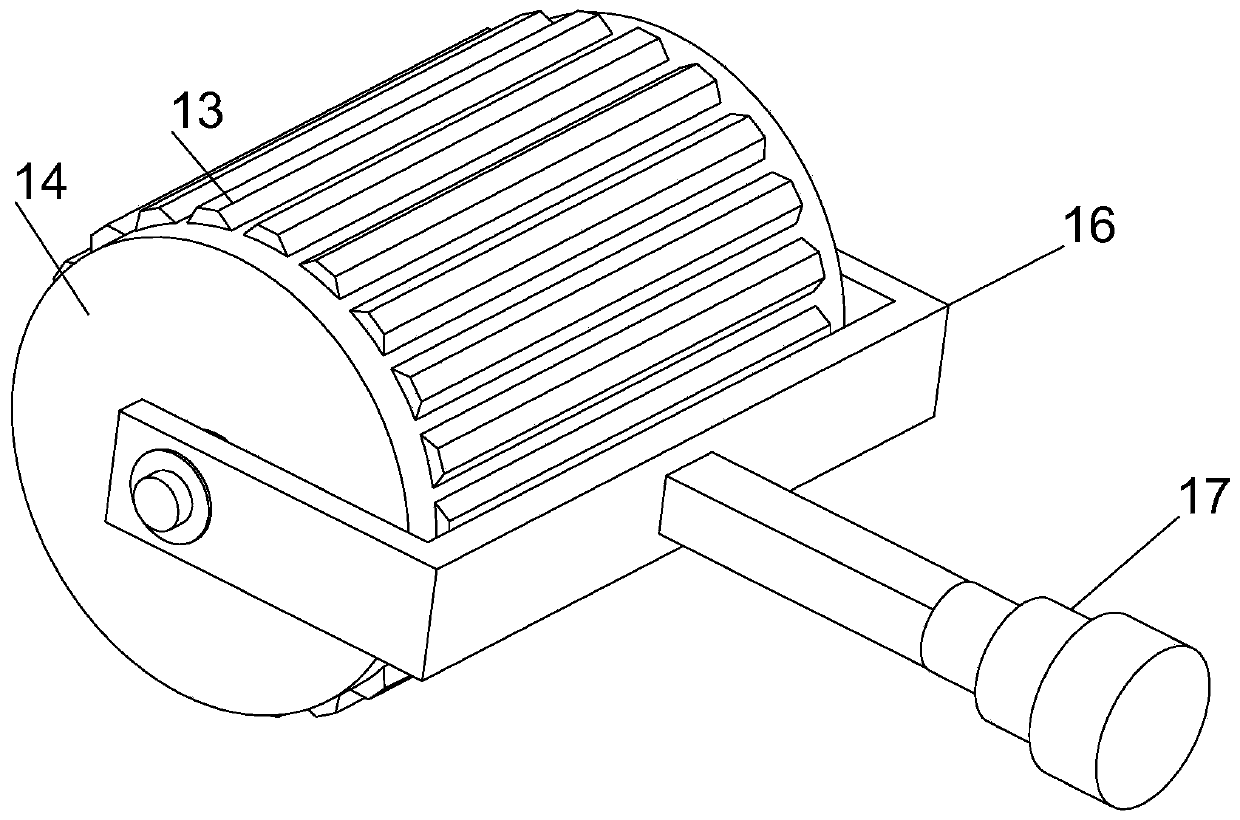

[0024] see Figure 1~3 , in an embodiment of the present invention, a regenerative concrete waste recovery device includes a vertically arranged support installation cylinder 19, a number of support installation columns 24 are arranged at an equal angle at the lower end of the support installation cylinder 19, and the upper middle position of the support installation cylinder 19 is vertical A feeding installation cylinder 8 is arranged vertically, and a crushing material guide cylinder 20 is vertically arranged at the bottom middle position of the supporting installation cylinder 19, and several discharge gates 21 are arranged at equal angles on the wall of the supporting installation cylinder 19 corresponding to the crushing material guiding cylinder 20. , the middle position of the feeding installation cylinder 8 is vertically provided with a material guide installation cylinder 6, the lower end of the material guide installation cylinder 6 is fixed on the top of the support ...

Embodiment 2

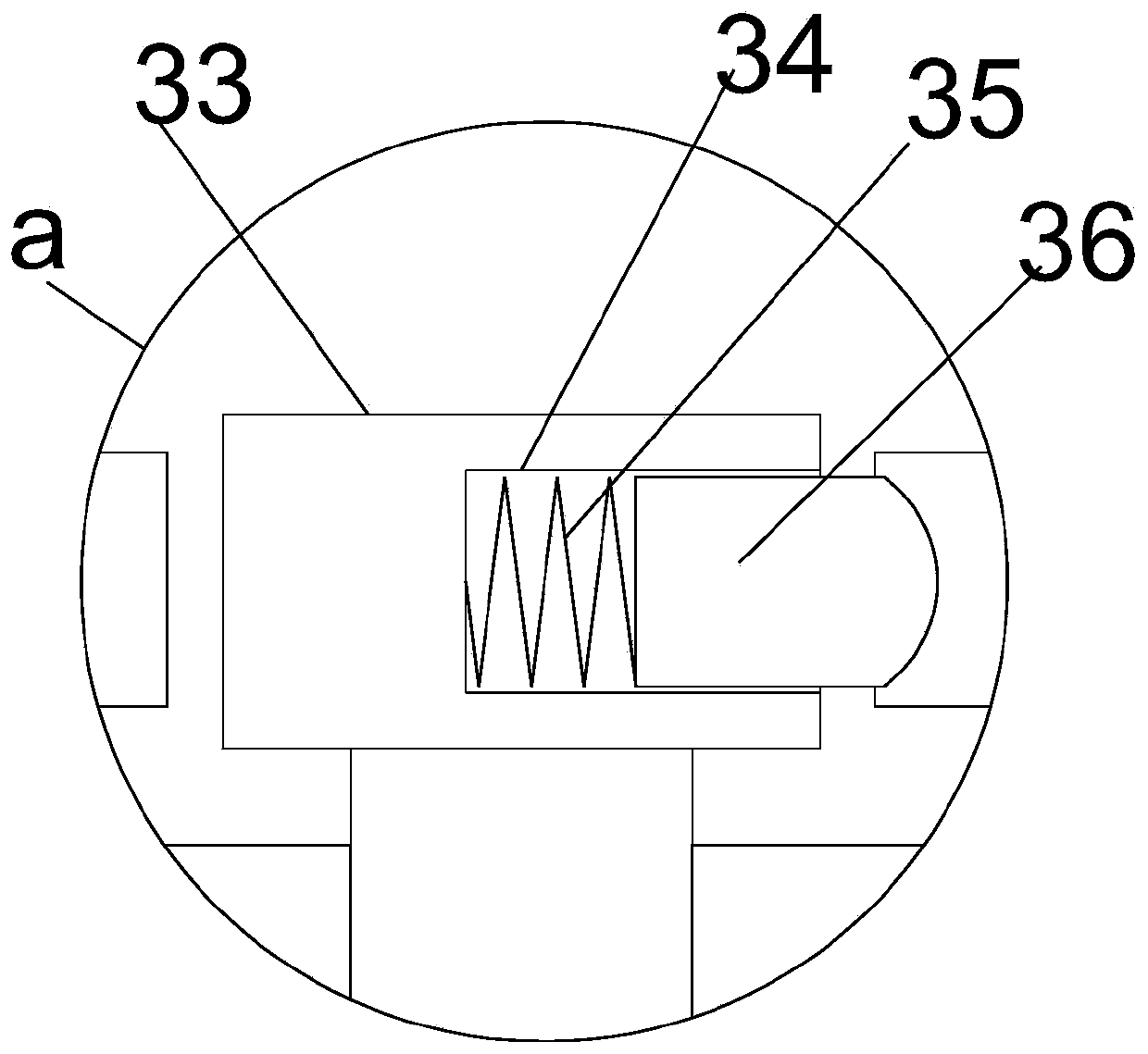

[0027] On the basis of Embodiment 1, the position of the displacement installation frame 16 is controlled by the electrically controlled telescopic column 17, so that the gap between the active crushing drum 11 and the passive crushing drum 14 changes, thereby changing the crushing accuracy, and the discharge gate 21 will Impurities that cannot pass through the conical filter screen 18 are exported, and the rotating mounting plate 33 rotates with the limit shaft 27, so that the guiding telescopic column 36 hits the static crushing column 23 intermittently, realizing the vibration of the device and improving the efficiency of material falling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com