3D printing porous imitated trabecular arc-shaped intramedullary shank

A 3D printing and intramedullary handle technology, applied in the field of medical device research, can solve the problems of normal mechanism damage, affecting function and recovery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

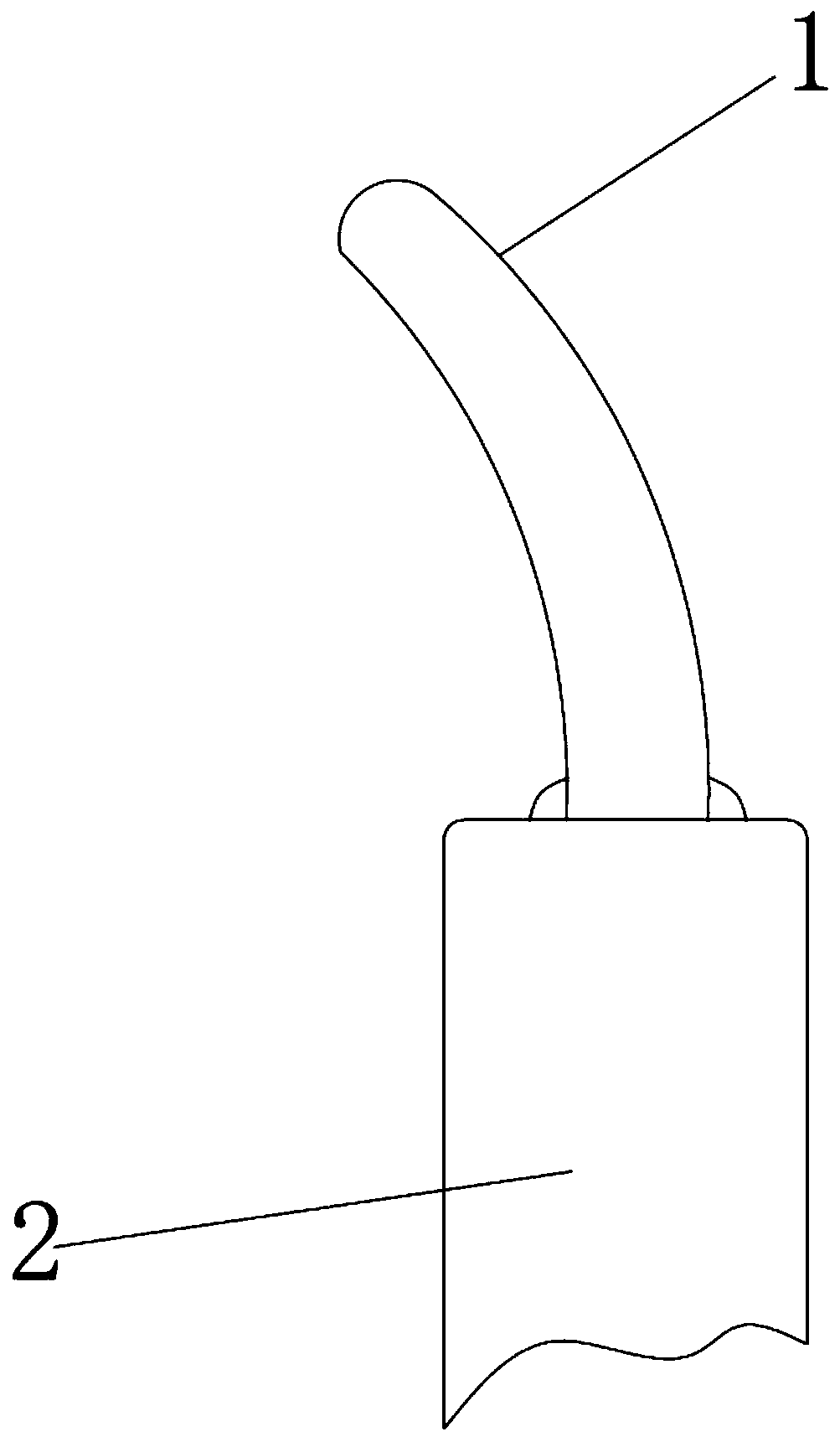

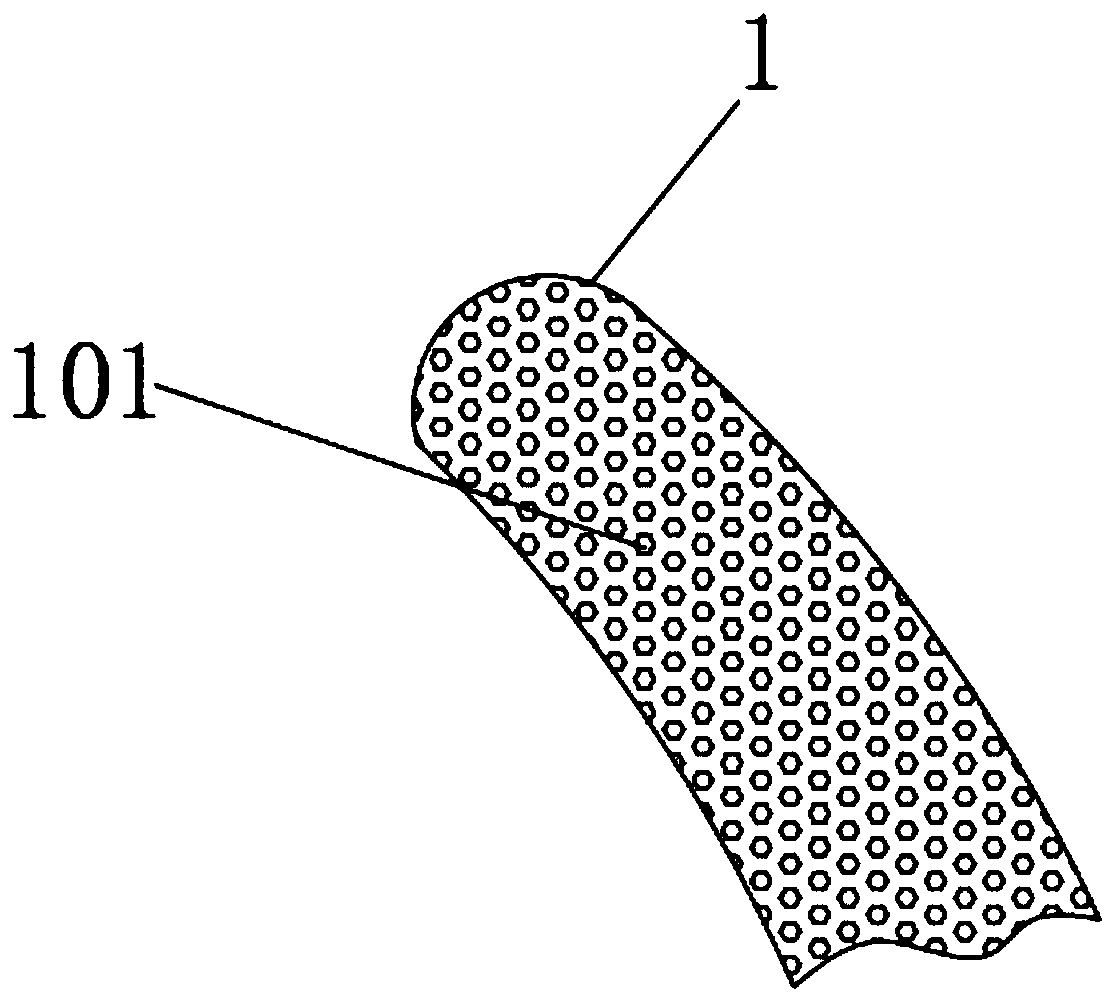

[0021] A 3D printed porous imitation trabecular arc-shaped intramedullary handle of the present invention comprises: a medullary needle part 1 and a connecting part 2; Trabecular bone structure, the needle portion 1 is provided with a number of pores 101 .

[0022] Preferably, the pores 101 are arranged in multiple layers from outside to inside, the diameter of the pores 101 gradually decreases from outside to inside, and the porosity of the needle part 1 gradually decreases from outside to inside.

[0023] Preferably, the radial dimension of the needle part 1 gradually decreases from the base to the end.

[0024] Further, the curvature of the outer edge of the medullary needle part 1 is greater than that of the inner edge.

[0025] Preferably, the base of the n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com