Seeding tray structure assembly and seeding device

A technology for structural components and seeding devices, applied in the directions of planter parts, sowing, planting methods, etc., can solve the problems of not being able to simply replace the use, the damage rate of damaged seeds, and the increased cost of mechanized equipment, and achieve the path for seeds to enter the hole. Smooth, conducive to membrane perforation, saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

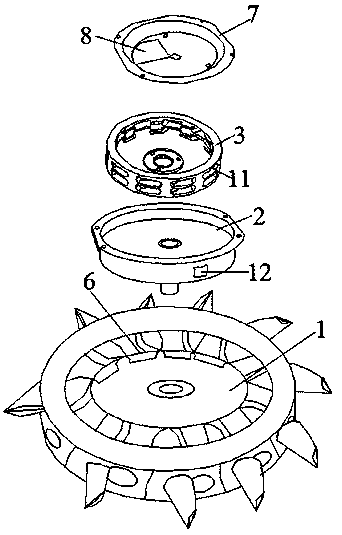

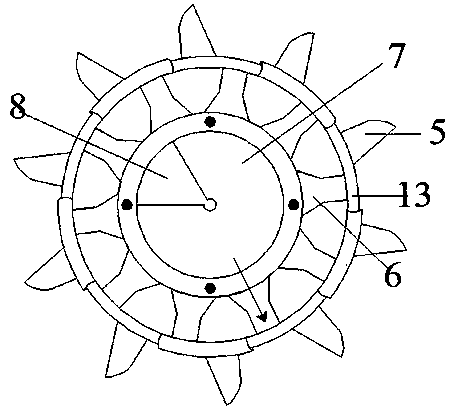

[0052] like Figure 1-8 As shown, a kind of sowing disk structure assembly includes an outer sowing disk 1, a fixed disk 2 and a seeding screen 3, and the outer sowing disk 1, the fixed disk 2 and the seeding sieve 3 shaft holes are on the same axis, and the outer sowing disk 1 is embedded with There is a fixed disc 2, the side wall of the fixed disc 2 is provided with a seeding hole 12, the seeding screen 3 is placed in the fixed disc 2, and the outer sowing disc 1, the fixed disc 2 and the seeding screen 3 are integrally fixedly connected by a screw nut, and finally The fixed state is that when the fixed disk 2 is erected, the horizontal plane is used as a reference, and the seed hole 12 on the fixed disk 2 is on the lower end side wall, and the angle formed with the horizontal plane is 10-30 ° (see Figure 7 ), the upper end of the fixed disk 2 is fixedly connected with the cover plate 7, and the outer side of the outer broadcast disk 1 includes ten arc-shaped engaging plat...

Embodiment 2

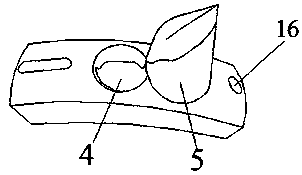

[0055] like Figure 9 As shown, embodiment 2 is a further improvement to the technical solution of embodiment 1. The inside of the seeding screen 3 is provided with a seed cleaning sheet 9, and the seed cleaning sheet 9 includes a guide sheet 901, and the outside of the guide sheet 901 matches the radian of the inside of the seeding screen 3. The outer side of the linear guide end of the lower end of the guide piece 901 is symmetrically provided with a single arc-shaped protrusion-902, and the single-arc-shaped protrusion-902 is placed in the seed hole-11 of the seeding screen 3. The benefit of this design is that the seeding of the seeding screen 3 The seeds in the hole 11 are cleaned out, and the guide sheet 901 acts as a seed guide; the principle of the so-called seed cleaning sheet 9 in this part is that when seeds such as peanuts enter the seed outlet 11 of the seeding screen 3, they will stay inside , and the function of seed clearing sheet 9 is exactly that seed is sque...

Embodiment 3

[0057] like Figure 10 As shown, embodiment 4 is a further improvement to the technical solution of embodiment 3. The seed cleaning sheet 9 includes a guide sheet 901, the outside of the guide sheet 901 matches the radian of the inner side of the seeding screen 3, and the outer side of the straight guide end of the lower end of the guide sheet 901 is symmetrically arranged. Continuous two-step arc-shaped protrusions 903, the two-step arc-shaped protrusions 903 are placed in the seed outlet 11 of the seeding screen 3, the advantage of the two-step arc-shaped protrusions 903 compared with a single arc-shaped protrusion 902 is that it can damage the seeds Small, because the existing single arc-shaped protrusion-902 on the market is a structure that matches the seed hole-11 of the seeding screen 3, the radian is steep, and the seeds will be squeezed by the single arc-shaped protrusion-902 when passing through the seed hole-11 pressure, thereby damaging the seeds, and after the sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com