Novel acoustic motor and implementation method thereof

A technology of sound waves and motors, which is applied in the field of new sound wave motors and its realization, can solve problems such as failure to meet customer requirements, small torque, etc., achieve good vibration effect and strengthen the effect of driving magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

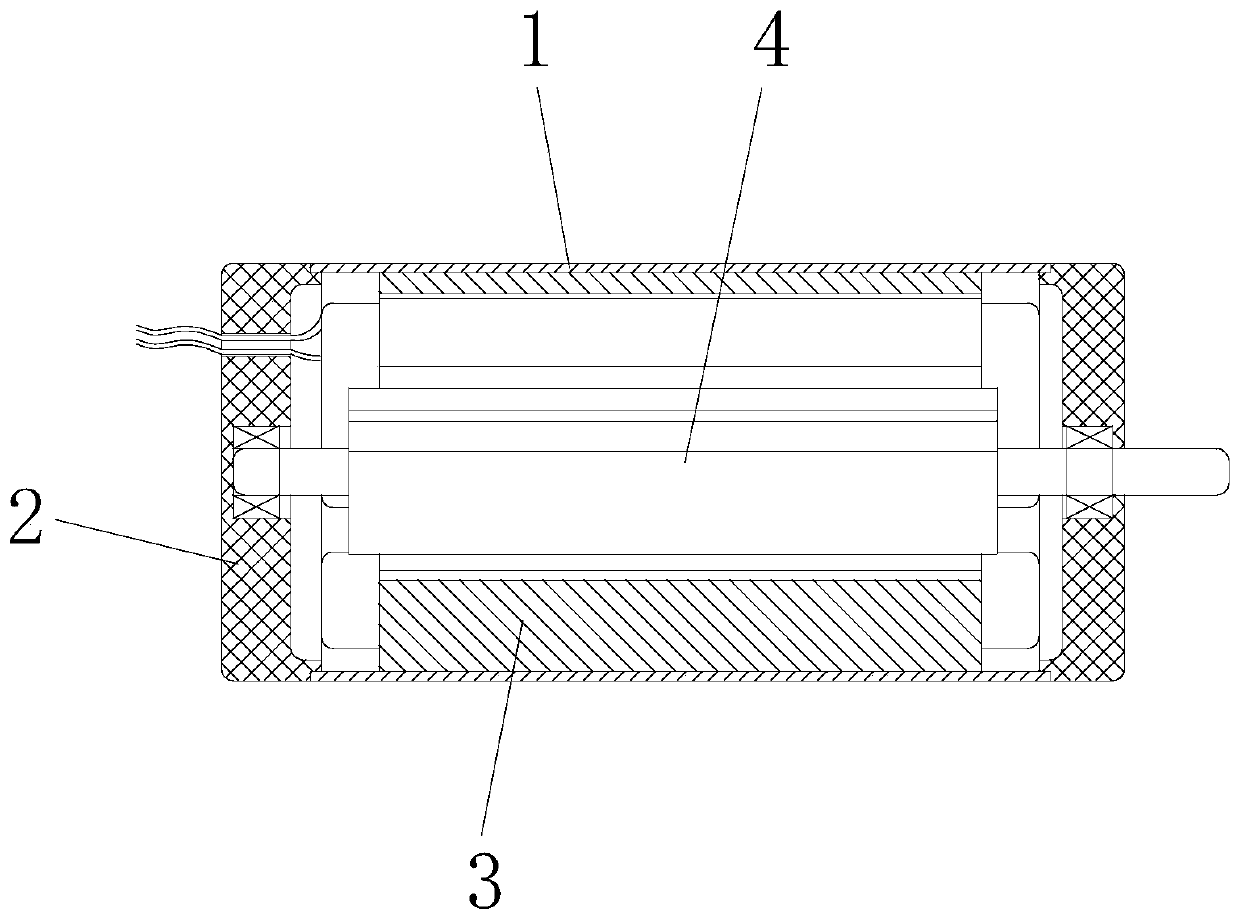

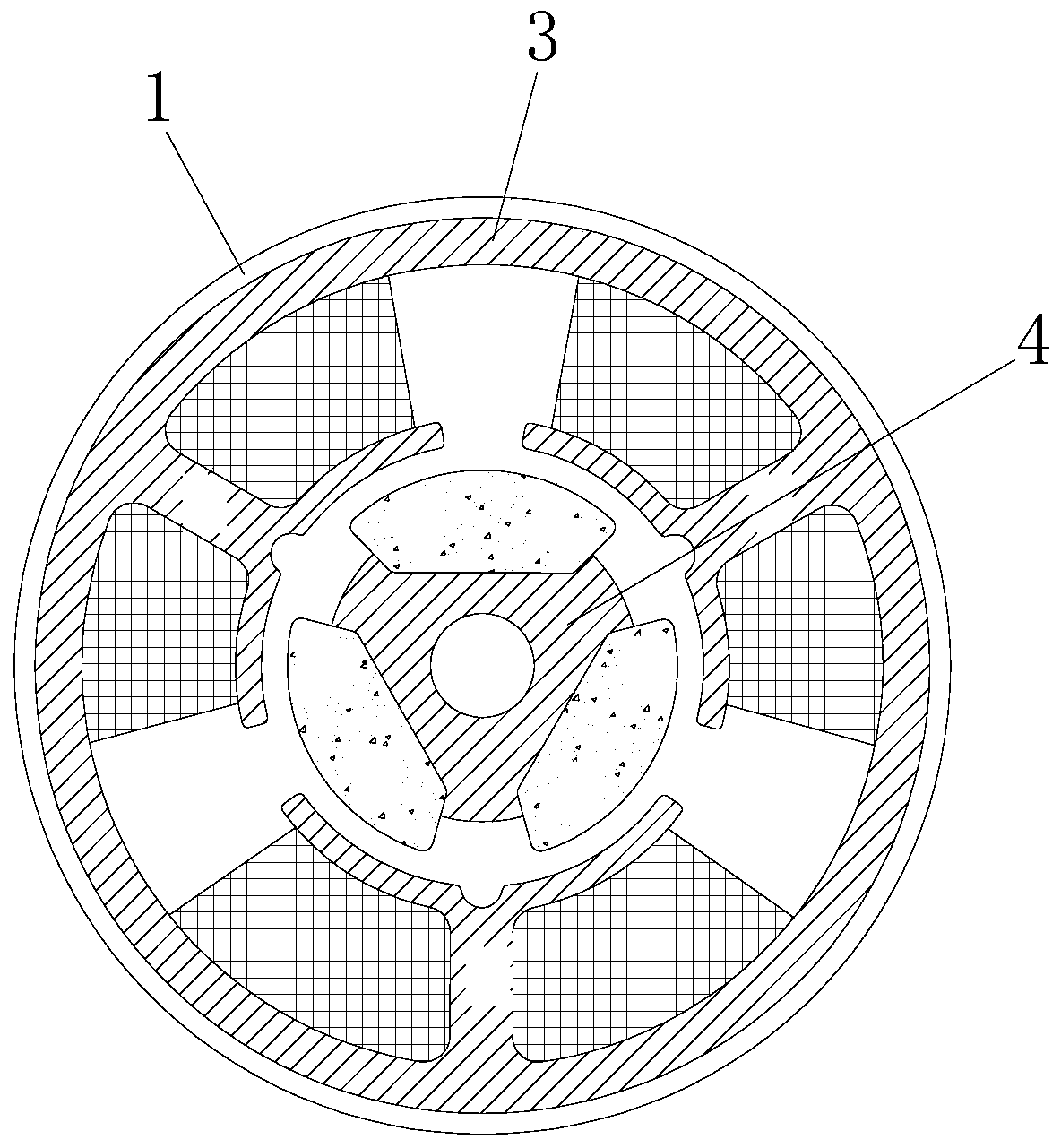

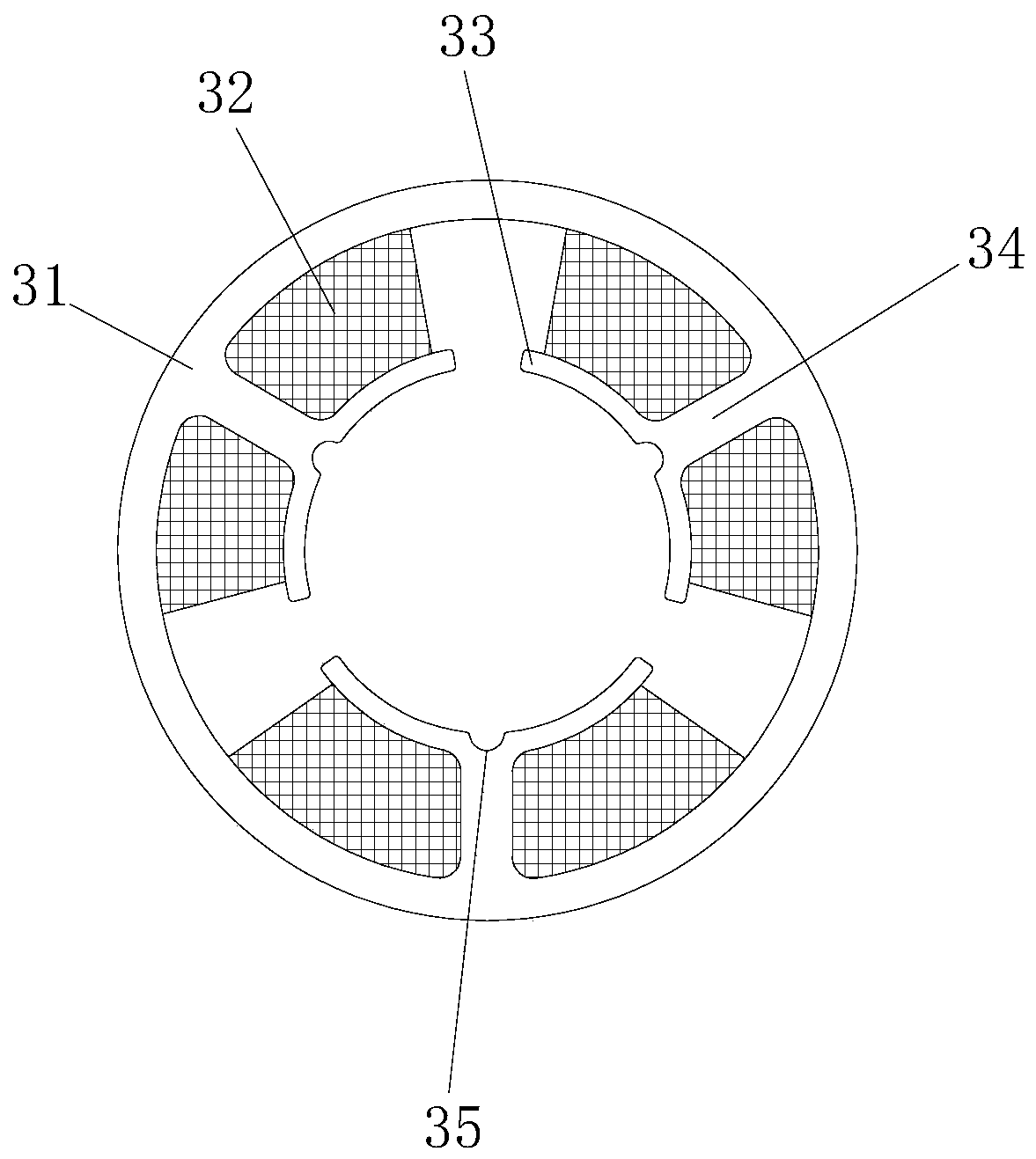

[0033] see Figure 1-7 , the present invention provides the following technical solutions: a new type of acoustic wave motor, including a casing 1, a stator assembly 3 is provided on the inner wall of the casing 1, a rotor assembly 4 is provided inside the stator assembly 3, and one side of the casing 1 is connected with The end cover 2, the rotor assembly 4 are rotationally connected with the end cover 2 and the casing 1, the stator assembly 3 includes a stator core 31, a coil 32 and a winding core 34, wherein the stator core 31 is connected to the inner wall of the casing 1, and the stator The iron core 31 is a hollow cylindrical structure. Three winding cores 34 are arranged at equal intervals on the inner wall of the stator iron core 31 . Coils 32 are wound on the winding cores 34 . The three coils 32 are connected in parallel.

[0034] Further, a pole plate 33 is connected to the side of the winding core 34 away from the stator core 31 , and the pole plate 33 has an arc-s...

Embodiment 2

[0043] The difference between this embodiment and Embodiment 1 lies in: further, a notch 35 is provided at the middle position of the pole plate 33 .

[0044] By adopting the above-mentioned technical scheme, under normal circumstances, when the coil 32 is energized, the pole plate 33 will generate a corresponding magnetic field, and it will be evenly distributed on the surface of the pole plate 33; The notch 35 forms two magnetic fields as boundaries.

[0045] Further, the implementation method of the novel acoustic wave motor described in the present invention includes the following steps:

[0046] (1), the stator assembly 3: the stator core 31, the pole plate 33 and the winding core 34 are stamped and formed by a magnetically conductive material, and the coils 32 are wound in the same direction on the three winding cores 34, and the three coils 32 are connected in parallel;

[0047] (2) Rotor assembly 4: the rotor core 41 is connected to the rotating shaft 43 through an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com