Rapid calculation method for mold water heating and mold temperature controller parameter calculation method

A fast calculation and mold heating technology, applied in design optimization/simulation, etc., to achieve fast solution, efficient mold temperature machine parameter calculation, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

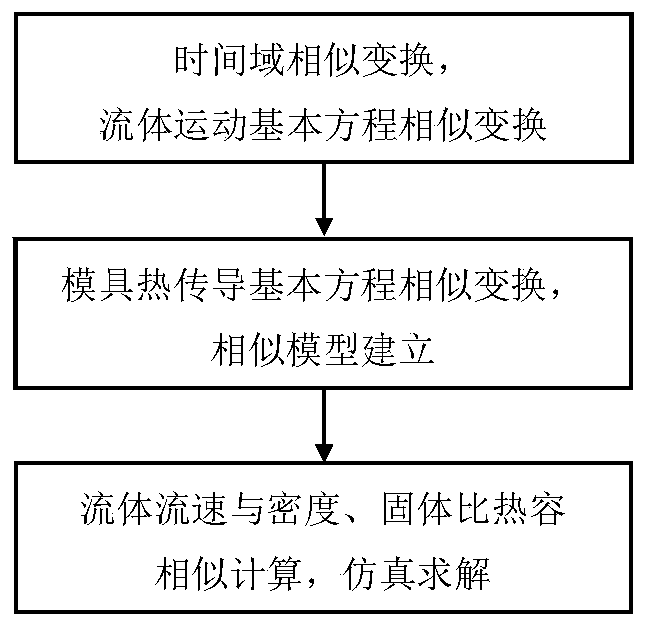

Method used

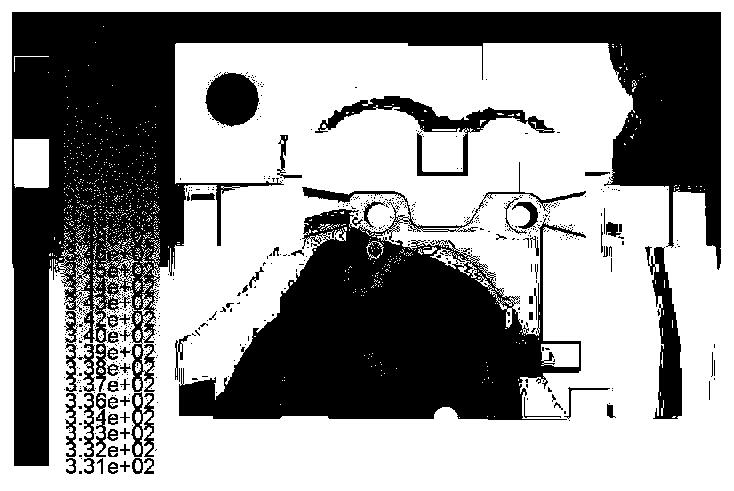

Image

Examples

Embodiment 1

[0130] Embodiment 1: 267 mold heating.

[0131] It is known that the ambient temperature is 25°C, the initial mold temperature is 25°C, the hot water temperature is 90°C, the water flow velocity is 2.7m / s, the heating time □=1800s, find the mold temperature after the heating time □.

[0132] The steps that adopt fast algorithm of the present invention to calculate are as follows:

[0133] Step 1: Perform similarity transformation on heating water attributes.

[0134] According to the selection requirements of the conversion coefficient α, that is, the water velocity should be less than 1, and the similar conversion coefficient α=1 / 6 is taken, then the heating time of the similar model is αβ=1800 / 6=300, and the similar transformation of the heating water speed and density is as follows: ( Water density before transformation is ρ f =1))

[0135] ρ f1 = ρ f / α=6ρ f =6×10 -9 kg / m 3 ;

[0136] u 1 =αu=u / 6=0.45m / s.

[0137] Step 2: Perform a similarity transformation on t...

Embodiment 2

[0143] Embodiment 2: 295 mold heating.

[0144] It is known that the ambient temperature is 25°C, the initial mold temperature is 25°C, the hot water temperature is 90°C, the water flow velocity is 3.68m / s, and the heating time□=1800s.

[0145] Adopt its calculation steps of fast algorithm of the present invention as follows:

[0146] Step 1: Perform similarity transformation on heating water attributes.

[0147] Get similar transformation coefficient α=1 / 6, then the heating time of similar model is αβ=1800 / 6=300, and heating water velocity and density similar transformation are as follows: (ρ before transformation f =1))

[0148] ρ f1 = ρ f / α=6ρ f =6×10 -9 kg / m 3 ;

[0149] u 1 =αu=u / 6=0.45m / s.

[0150] Step 2: Perform a similarity transformation on the mold solid properties.

[0151] Transform with the same similarity conversion coefficients as in step 1, where the similarity specific heat capacity parameter for solids is calculated as:

[0152] c 1 =c / 6.

[0...

Embodiment 3

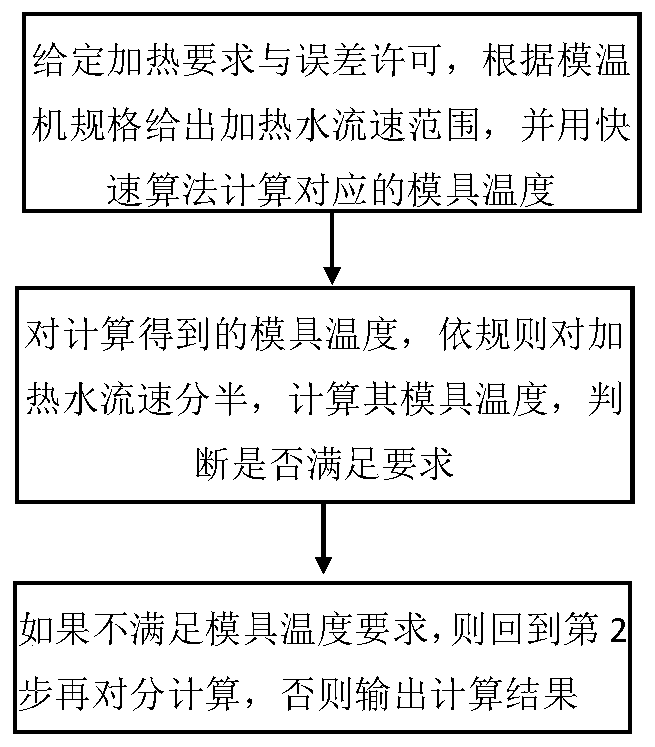

[0156] Embodiment 3: Calculation of the parameters of the water heating mold temperature machine.

[0157] The 295 mold is known, the ambient temperature is 25°C, the initial mold temperature is 25°C, the heating water temperature is 90°C, the heating time □=1800s, and the cross-sectional area of the water outlet of the known mold temperature controller is A=π×25mm 2 .

[0158] Requirements: Heat the mold temperature to 88°C within the specified heating time □, that is, T m =88°C, T in Kelvin temperature unit m =361.15K, find the required heating water flow.

[0159] Analysis steps:

[0160]1) Calculate the length of the mold waterway as 2.2m, round it up to 2m, and give the range of the hot water flow rate according to the range of the hot water flow rate of the mold temperature controller [u a ,u b ]=[1,4]m / s, allowable error ε=0.1;

[0161] Select a measuring point on the mold, that is, the temperature of the point represents the mold temperature, and the coordinate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com