A garbage pyrolysis gasifier

A technology of pyrolysis gasification and pyrolysis furnace, which is applied in the direction of incinerators, lighting and heating equipment, combustion types, etc., can solve the problems of low thermal conductivity, hinder the decomposition of plastic center parts, and low plastic decomposition efficiency, so as to improve contact area, the effect of increasing the contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] as attached figure 1 To attach Image 6 Shown:

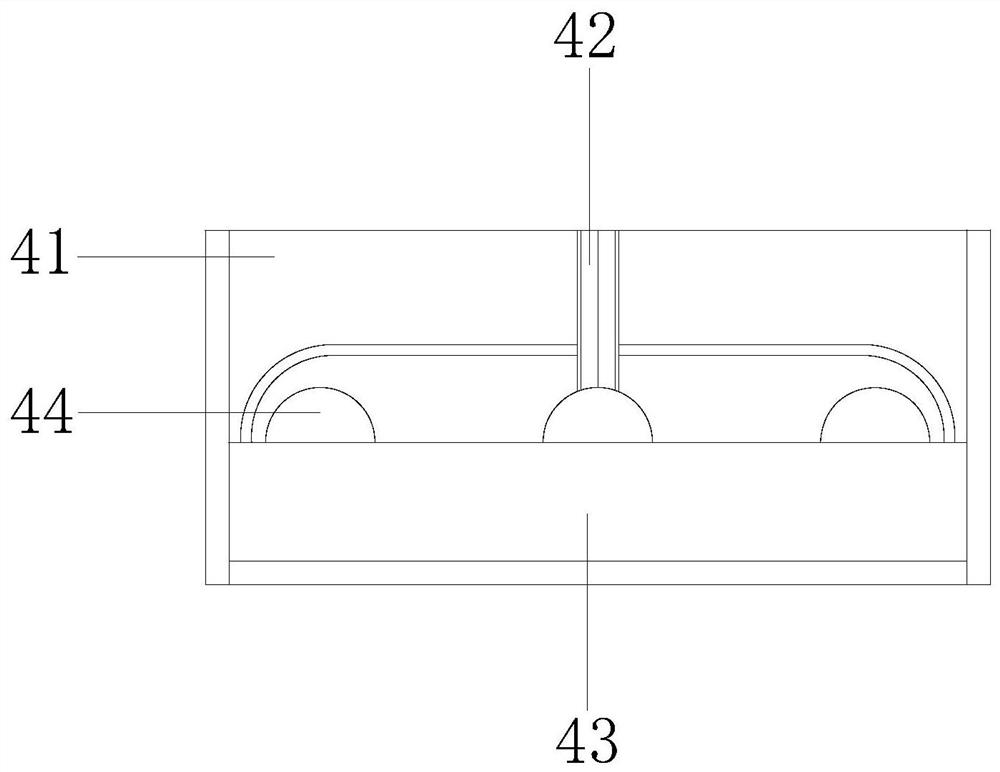

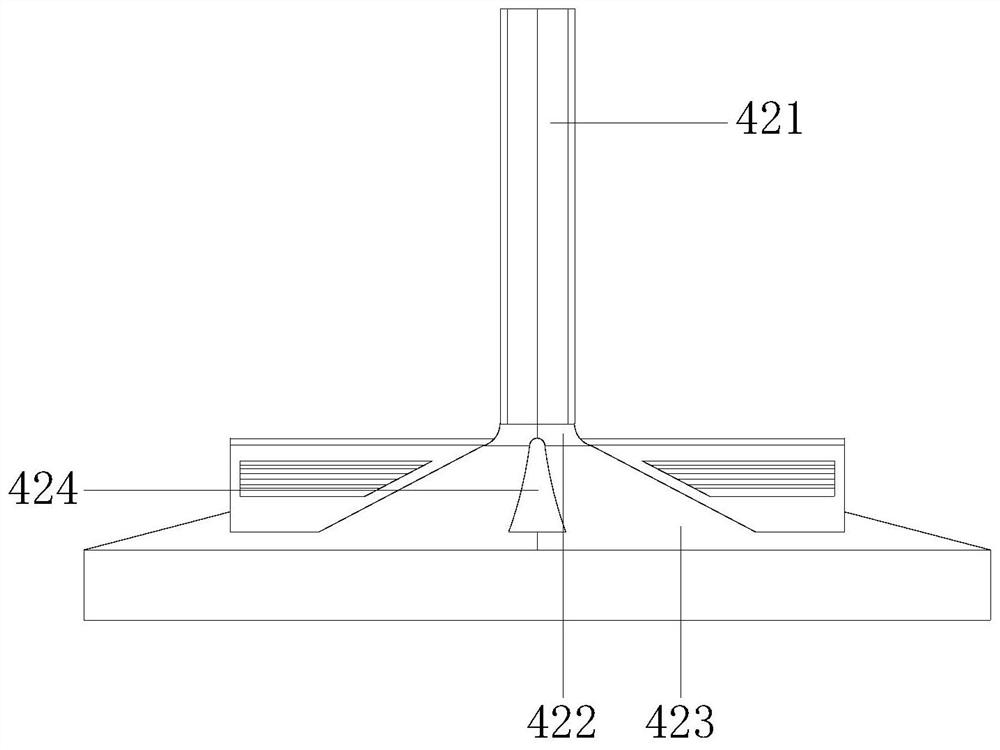

[0025] A garbage pyrolysis gasification furnace of the present invention, its structure includes an inlet 1, a pyrolysis furnace 2, an air outlet pipe 3, a turning mechanism 4, a steam inlet 5, and a burner 6, and the inlet 1 is installed on the upper end of the pyrolysis furnace 2 And communicate with each other, the upper end of the pyrolysis furnace 2 is embedded with an outlet pipe 3, the bottom of the pyrolysis furnace 2 is equipped with a turning mechanism 4, the steam inlet 5 is fixedly installed on the outside of the bottom of the turning mechanism 4, and the steam inlet 5 communicates with the burner 6, the turning mechanism 4 includes a housing 41, a rotating mechanism 42, an underflow mechanism 43, and a middle heat conduction mechanism 44, and the upper end of the housing 41 is fixedly installed on the lower end of the pyrolysis furnace 2 and communicates with each other. A rotating mechanism 42 is installed...

Embodiment 2

[0033] as attached Figure 7 To attach Figure 8 Shown:

[0034] Wherein, the middle heat conduction mechanism 44 includes a conduction pipe 441, a transfer pipe 442, and a heat conduction ball 443. Inside the bottom flow mechanism 43, a transfer pipe 442 is provided at the upper end of the conduction pipe 441 and communicates with each other. The transfer pipe 442 adopts The gap fit is installed inside the lower end of the heat conduction ball 443. The conduction pipe 441 has a circular structure, and is better installed at the junction of the inclined flow plate 423 and the bottom flow groove 431. The transmission pipe 442 and the heat conduction ball 443 are equipped with four One, to better pyrolyze the middle end of the melted plastic waste, and the transfer pipe 442 has a narrow upper part and a wider lower part, so as to improve the transfer efficiency of the steam generated by the steam inlet 5.

[0035] Wherein, the heat conduction ball 443 includes a limiting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com