An electric mixing device

A mixing and electric technology, applied in the direction of mechanical equipment, mixers, mixer accessories, etc., can solve the problems of heavy maintenance workload, low liquid dispensing capacity, high cost, etc., and achieve the effect of heavy maintenance work, high quality and high noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

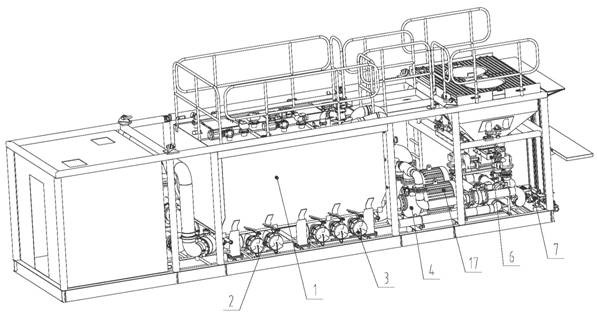

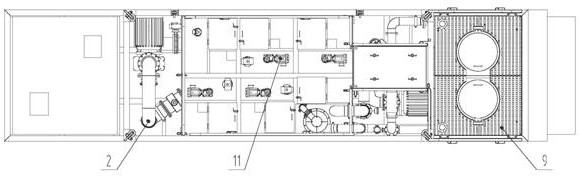

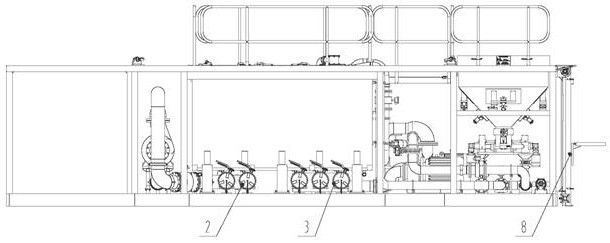

[0036]An electric mixing equipment provided by a preferred embodiment of the present invention realizes the above functions through the following technical solutions: the equipment includes a mixing tank 1, a discharge centrifugal pump 15, a discharge centrifugal pump motor 16, a suction centrifugal pump 4, and a suction centrifugal pump motor 17. Powder tank 9, lifting structure 8, electrical control room 14, high-energy mixing structure 5, suction manifold 3, liquid discharge manifold 2, liquid filling pump 7, agitator 11, screw conveyor 6, diffuser 10 And base 13, hanging frame 12. The number of the agitator is at least one, and this embodiment is the best embodiment, and the number of the agitator is four. The high-energy mixing structure 5 is assembled by a high-energy vortex mixer. A discharge centrifugal pump 15 is installed on one side of the mixing tank 1; a discharge centrifugal pump motor 16 is installed on the discharge centrifugal pump 15; There is an electrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com