Tube-well structure, dewatering construction system and method suitable for high-permeability alluvial strata

A technology of tube well dewatering and high permeability, which is applied in infrastructure engineering, construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

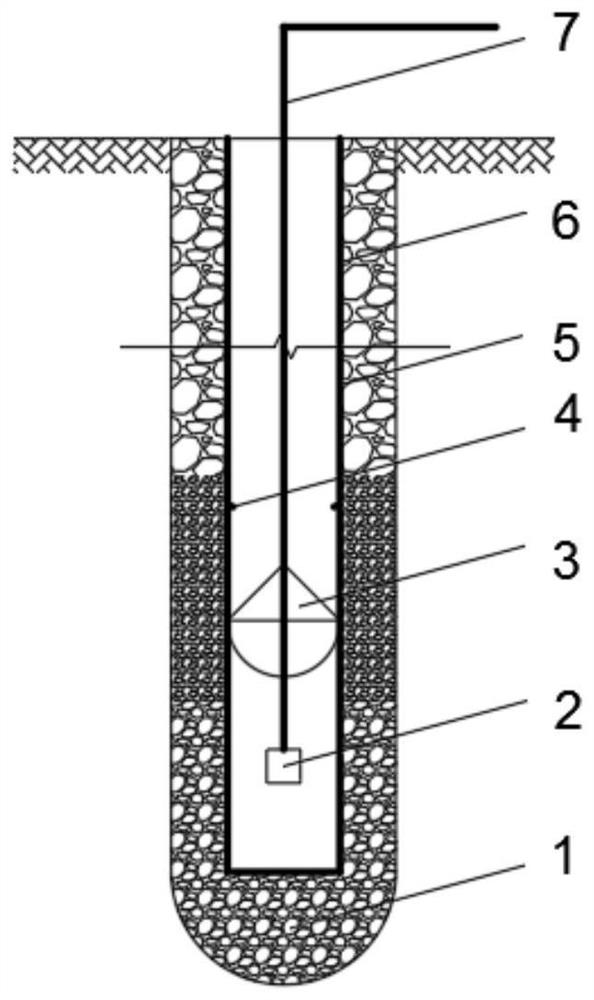

[0037] Attached below Figure 1-Figure 12 The present invention is described in detail, specifically, the structure is as follows:

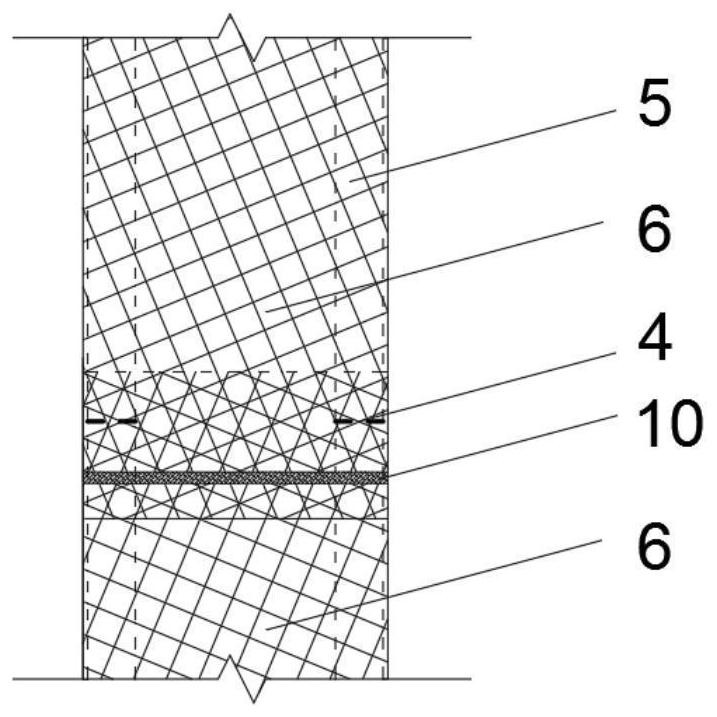

[0038] This embodiment provides a tube well structure suitable for high-permeability alluvial formations, including a well tube 5, a filter cloth 6, a filter material 1, a pipe joint 4, and a well seat 20, such as figure 1 As shown, the adjacent tube wells are connected through the pipe joints 4 , and the well base 20 is arranged at the end of the last tube well 5 . The filter cloth 6 is wrapped on the outside of the well pipe 5, and the filter material 1 is placed outside the filter cloth 6. During the drilling process of the tube well, the properties of the soil layers at each depth are strictly recorded, and corresponding filter materials are filled in according to the distribution and thickness of the soil layers. 1.

[0039] Filter cloth 6 is respectively provided with different order number, number of layers according to the property of c...

Embodiment 2

[0052] This embodiment provides a tube well dewatering construction system suitable for high-permeability alluvial formations, including a piston well cleaning device and the tube well structure described in Embodiment 1. The piston well cleaning device extends into the well pipe 5 to clean the well pipe. 5 The inner wall is cleaned.

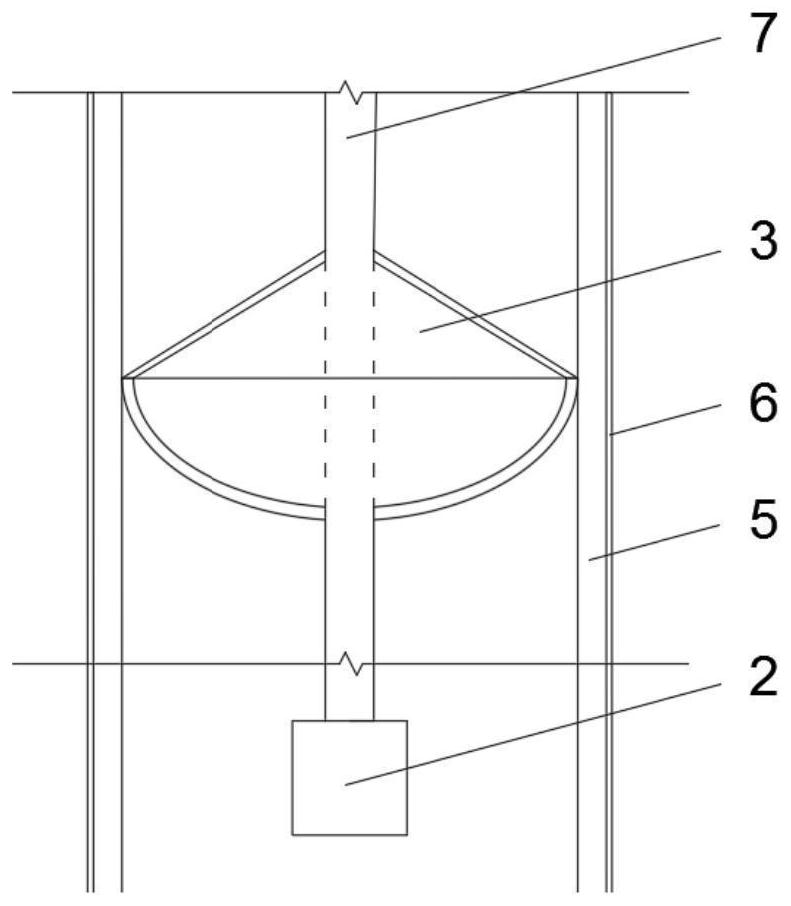

[0053] Such as figure 1 As shown, the piston well flushing device includes a piston 3 , a water pump 2 and a drain pipe 7 , and the drain pipe 7 passes through the piston 3 and is connected to the water pump 2 . Specifically, such as image 3 As shown, the piston 3 is a solid structure, the upper end of which is a cone, and the lower end is set as a hemisphere to reduce the resistance when moving the piston up and down. The center of the piston 3 reserves a hole for the drain pipe 7 to pass through. The method for flushing the well with the piston 3 of this embodiment is simple and easy to implement, and meets the requirement of simultaneous w...

Embodiment 3

[0055] This embodiment provides a tube well dewatering construction method suitable for high-permeability alluvial formations, using the tube well dewatering construction system described in Example 2, and the construction steps are: forming holes→running the tube well→filling the filter material→flushing the well.

[0056] specific:

[0057] (1) Preparation stage:

[0058] According to the geotechnical engineering survey strata, it is necessary to order different downwater pipe joints suitable for different strata.

[0059] (2) Hole forming:

[0060] The process of drilling and forming holes is recorded and corrected for surveying formations and different well pipes. Different drilling methods and different mud ratios are formulated according to different formations; specifically, for soft clay, sandy soil and other formations with sand inclusions, rotary drilling, auger drilling and other construction methods can be used for hole construction; for dense pebble gravel forma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com