Production method of transparent leather

A production method and leather technology, applied in leather surface treatment, special leather manufacturing, small raw hide/large raw hide/leather/fur treatment, etc., can solve the problem that the production method of transparent leather has not been reported, and the quality of finished products is difficult to be guaranteed and reduced. Leather physical and mechanical properties and other issues, to achieve the effect of strong practicability, flexible production and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

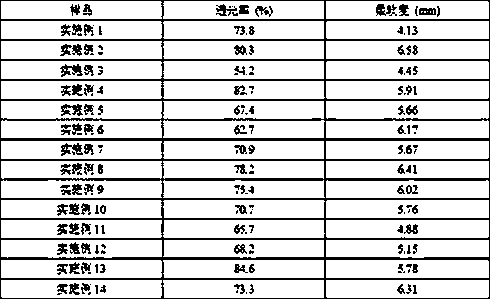

Examples

Embodiment 1

[0020] The deashed and softened pig head skin (thickness 1.0mm) is fully washed in the drum until the total ash content of the bare hide is less than 0.5%, and then it is taken out of the drum for 30 minutes, and weighed as the following operating materials; The polyoxypropylene stearate surfactant (HLB value 8.0) is dissolved in water with 10% of the weight of the bare hide, and then added to the drum, and rotated for 60 minutes after casting the skin; dissolve an appropriate amount of sodium hydroxide with 15% of the weight of the bare hide, Add to the drum in 4 times, rotate the drum for 20 minutes after each addition, and continue to rotate for 45 minutes after the addition. At this time, the pH value of the bath liquid is 11.5; the skins that have completed the above operations are taken out of the drum and then stretched to dry. The drying temperature is 35 ℃, the production of transparent leather is completed after complete drying.

Embodiment 2

[0022] The deashed and softened pig split skin (thickness 0.5mm) is fully washed in the drum until the total ash content of the bare hide is less than 0.2%, and then it is taken out of the drum for 30 minutes, and weighed as the following operating material benchmark; % of sorbitan trioleate surfactant (HLB value 1.8) is dissolved in 20% of the weight of bare hide in water, then added to the drum, and rotated for 30 minutes after casting the skin; dissolve an appropriate amount of sodium carbonate with 5% of the weight of bare hide in water , adding to the drum in 2 times, rotating the drum for 10 minutes after each addition, and continuing to rotate for 15 minutes after adding, at this time, the pH value of the bath solution is 9.5; after the above-mentioned operations are completed, the skin is stretched out of the drum and dried on a stretcher. 35°C, the production of transparent leather is completed after complete drying.

Embodiment 3

[0024] The deashed and softened cow split hide (thickness 2.0mm) is fully washed in the drum until the total ash content of the bare hide is less than 0.5%, and then it is taken out of the drum for 30 minutes, and weighed as the following operation material benchmark; % ethylene glycol fatty acid ester surfactant (HLB value 2.7) is dissolved in 15% water of the weight of bare skin, and then added to the drum, and rotated for 180 minutes after casting the skin; dilute an appropriate amount of formic acid with 10% water of the weight of bare skin, and divide it into 3 Add to the drum one time, and rotate the drum for 60 minutes after each addition, and continue to rotate for 90 minutes after the addition. At this time, the pH value of the bath liquid is 4.3; after the skins that have completed the above operations are taken out of the drum, they are stretched and dried at a drying temperature of 30 ° C. The production of transparent leather is completed after complete drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com