Fixed grain distributor of grain dryer

A technology for grain dryers and grain distribution, which is applied in the directions of transportation and packaging, loading/unloading, slideway, etc., and can solve the problems of loose dust, single function of grain distributors, and physical injuries of staff, so as to ensure the location and guarantee Airtightness, the effect of preventing dust from spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

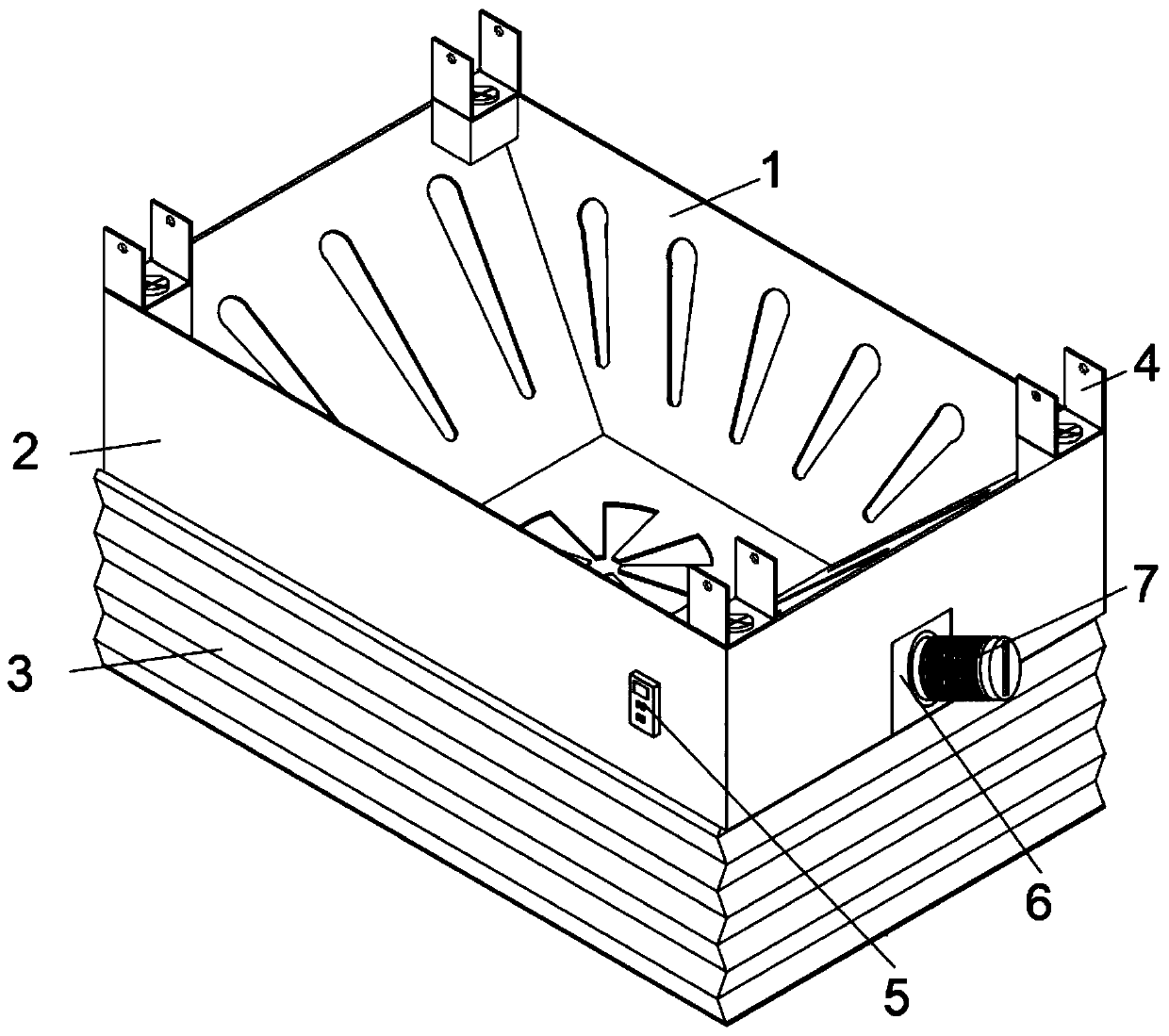

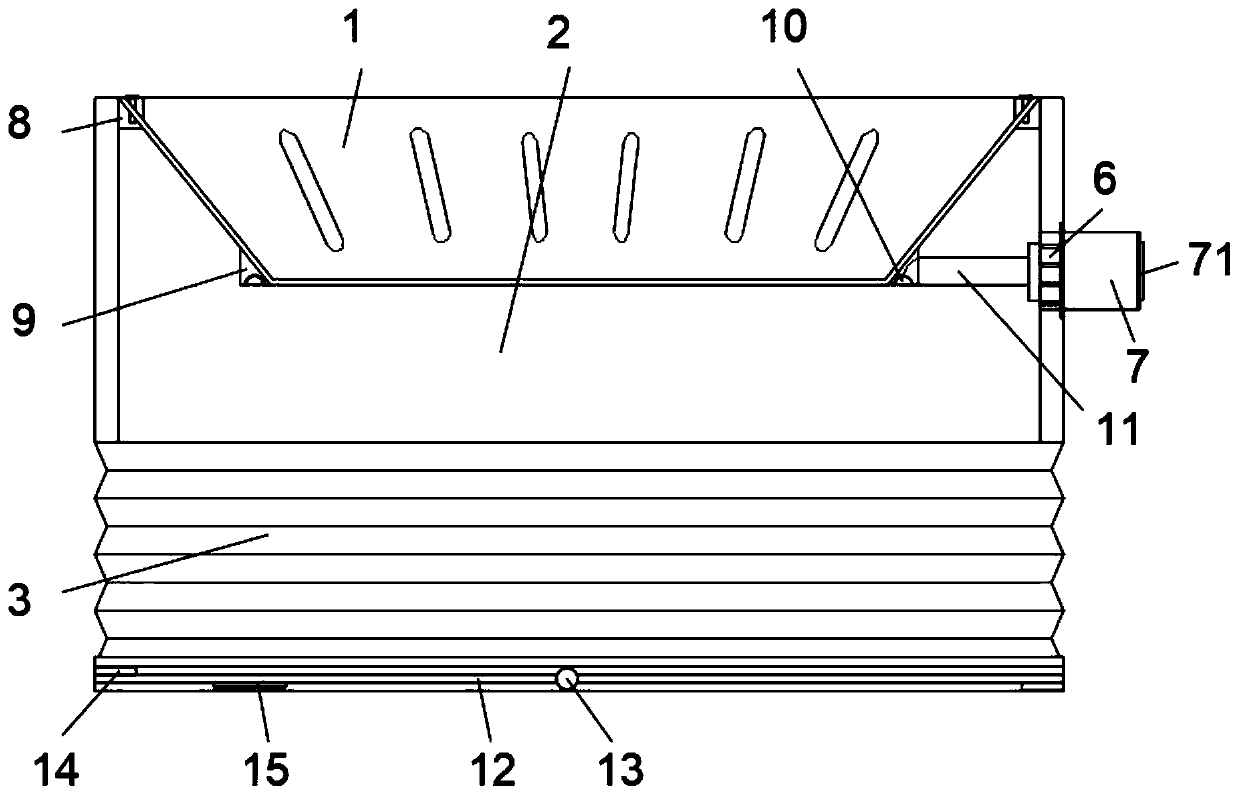

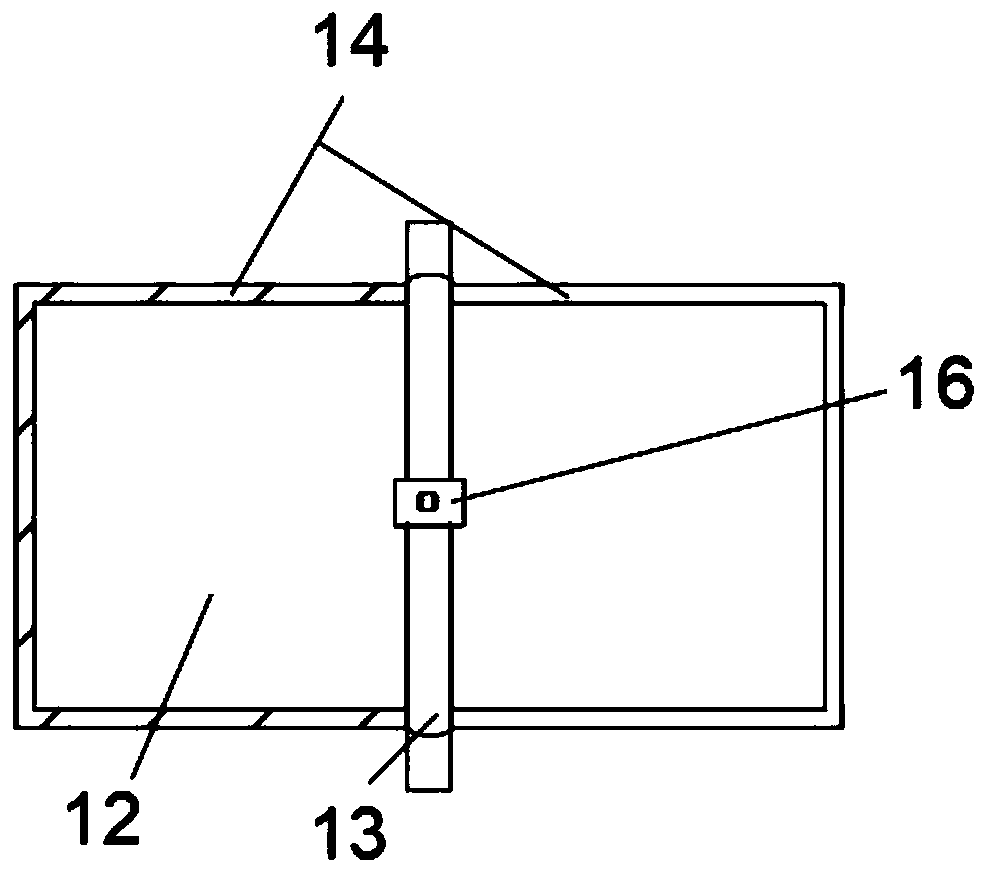

[0027] The following is attached figure 1 , to further illustrate a specific embodiment of the fixed grain distributor of the grain dryer of the present invention. The fixed grain distributor of a grain dryer in the present invention is not limited to the description of the following embodiments.

[0028] This embodiment provides the specific structure of a fixed grain distributor of a grain dryer, such as Figure 1-4 As shown, a fixed grain distributor of a grain dryer includes a grain distribution tank 1, a holding tank plate 2 and a grain storage tank 3 arranged sequentially from top to bottom;

[0029] The bottom and the wall of the grain distribution tank 1 are provided with a number of grain leakage holes for grain distribution, and the four corners of the top of the grain distribution tank 1 are welded with pull rods for fixing the grain distribution tank 1 to the grain dryer. After the fixed claw 4 on the top is snapped into the slot plate 2, the grain distribution t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com