Circuit board caching device driven by magnetic wheels

A circuit board and magnetic wheel technology, applied in the field of semiconductors, can solve problems such as operation accidents, powder generation, gear oil mist generation, etc., to achieve the effect of improving operation reliability, improving stability and reliability, and avoiding misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is further elaborated below by specific embodiment:

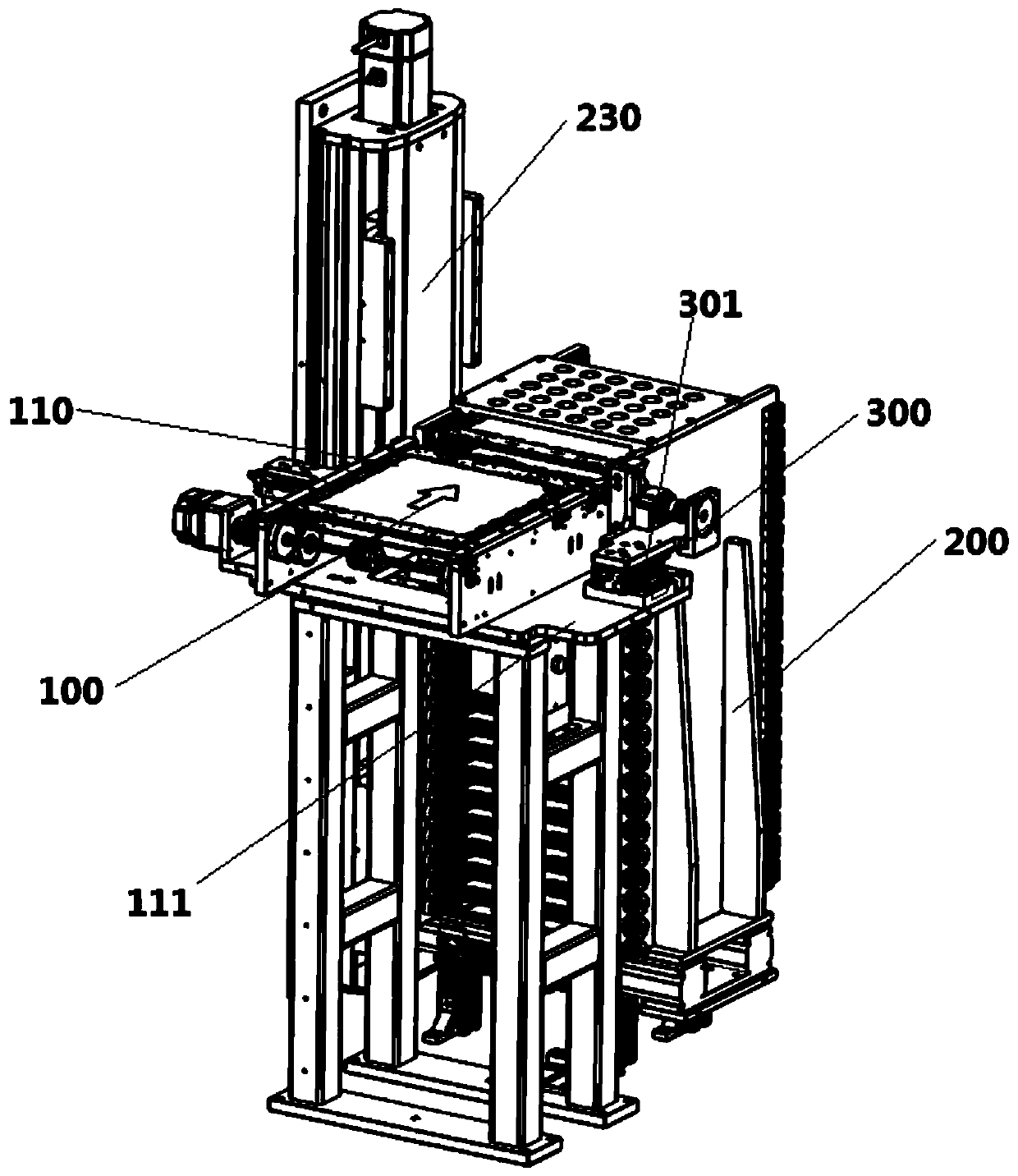

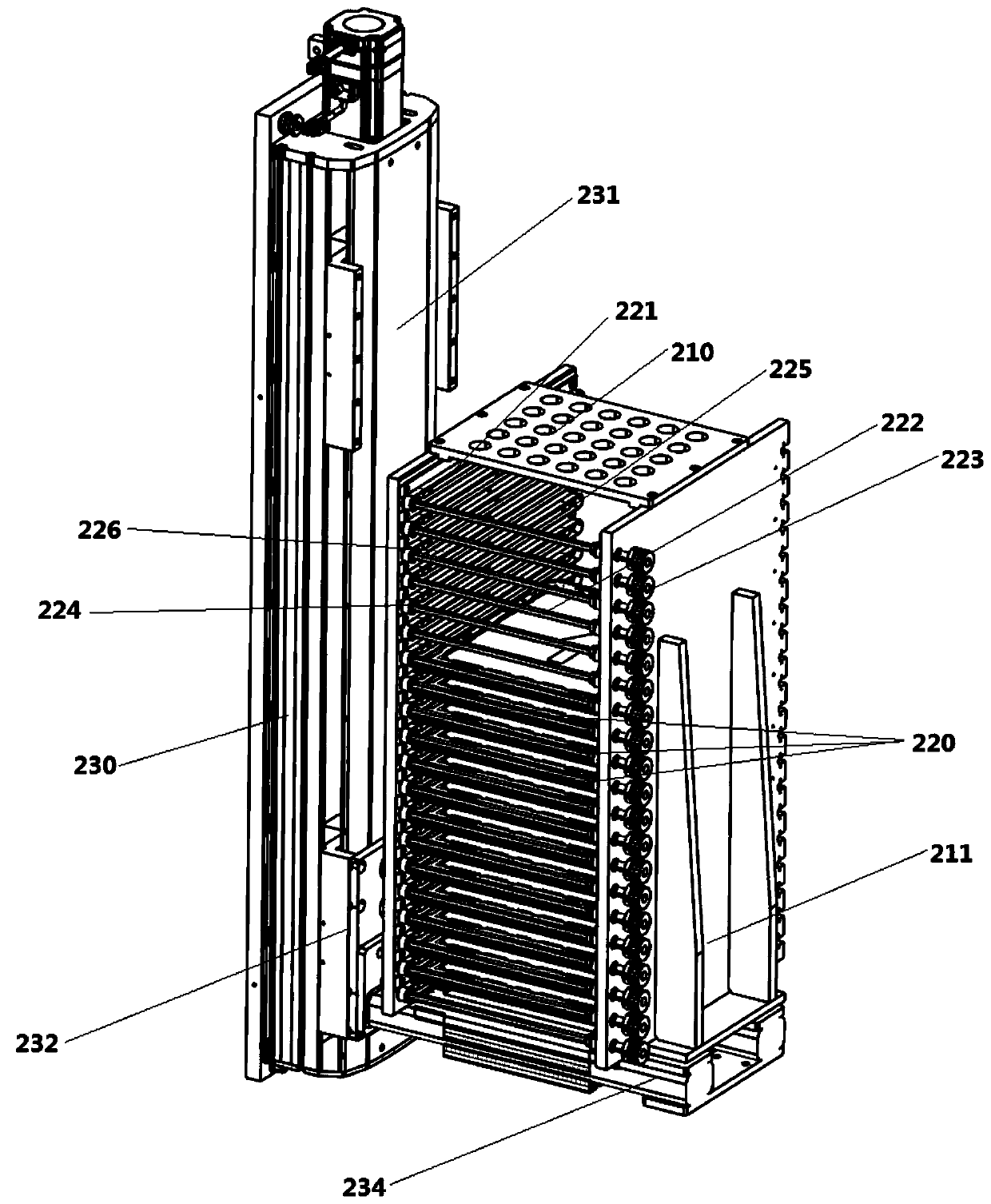

[0029] Such as figure 1 As shown, a circuit board buffering device driven by a magnetic wheel includes a board feeding mechanism 100 , a buffering mechanism 200 and a driving mechanism 300 .

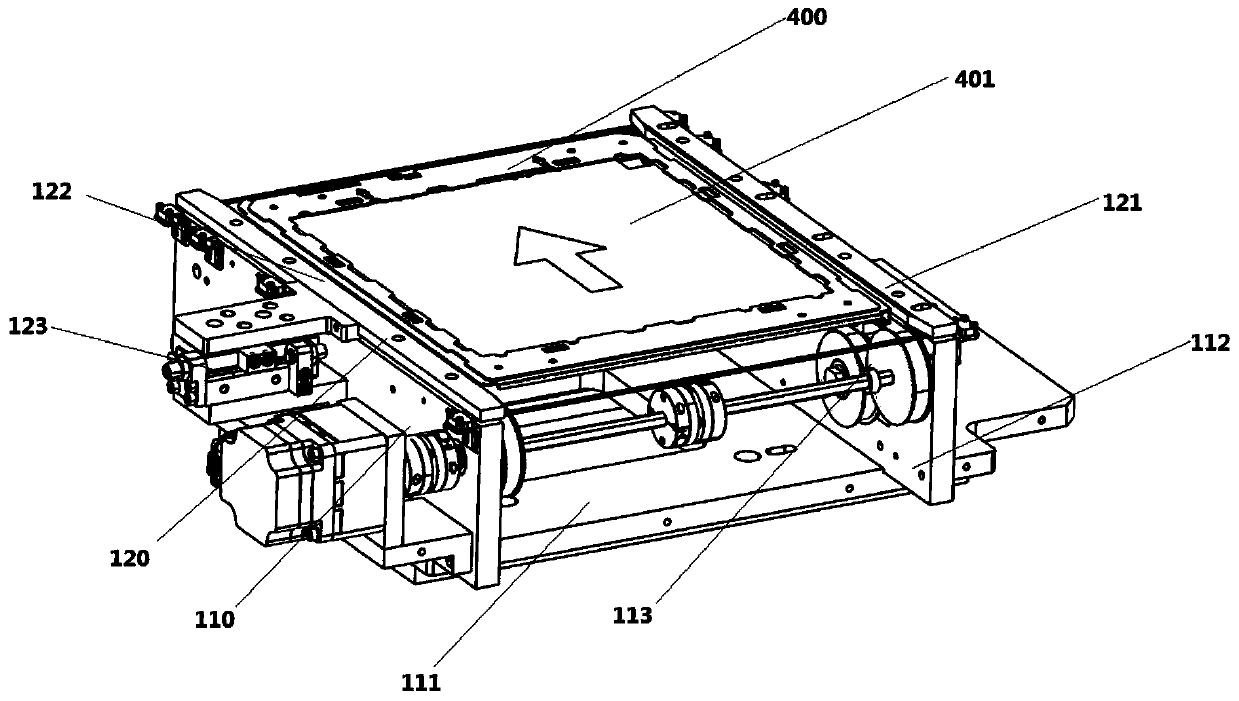

[0030] Such as figure 2 As shown, the plate feeding mechanism 100 includes a conveying platform 110, and the conveying platform 110 is conveyed by a platen 111, two side plates 112 arranged on both sides of the platen 111, and two groups of two groups separately arranged on the inner surfaces of the two side plates 112. Belt 113 constitutes. The upper surfaces of the two sets of conveyor belts 113 are at the same horizontal position. The driving wheels of the two groups of conveyor belts 113 are worn with drive shafts, and one end of the drive shafts stretches out to the outside of the side plate 112 and is connected with the motor, which drives the synchronous operation of the two groups of conveyor b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com