Thickness measuring and gluing platform for isolating membranes on two sides of wound battery cell

A technology of thickness measurement and battery cell, which is applied in the direction of coating, measuring device, battery assembly machine, etc., can solve the problems of interrupted track of isolation film, glue cannot be applied, glue accumulation, etc., so as to save installation space and ensure distance accuracy , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

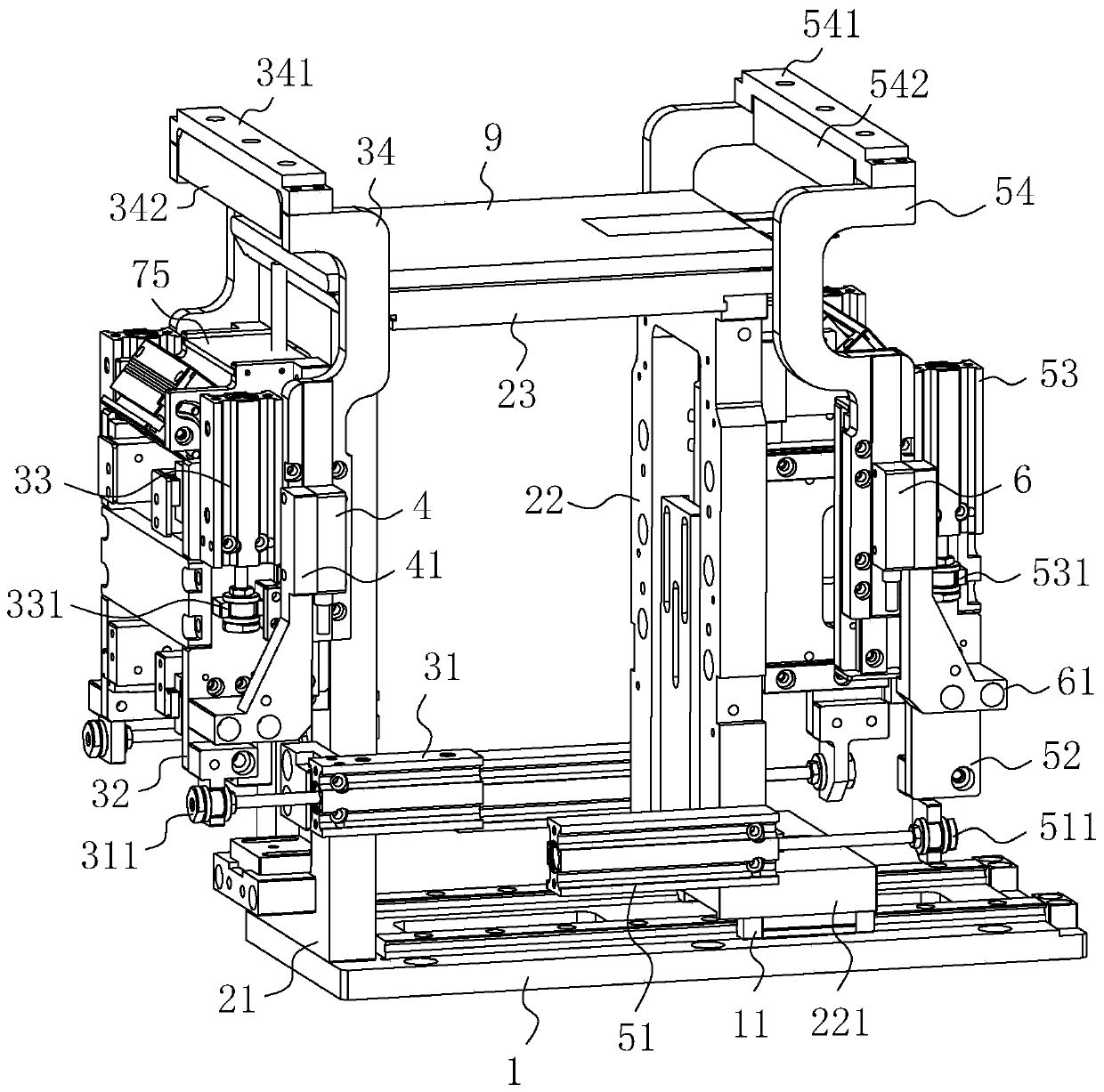

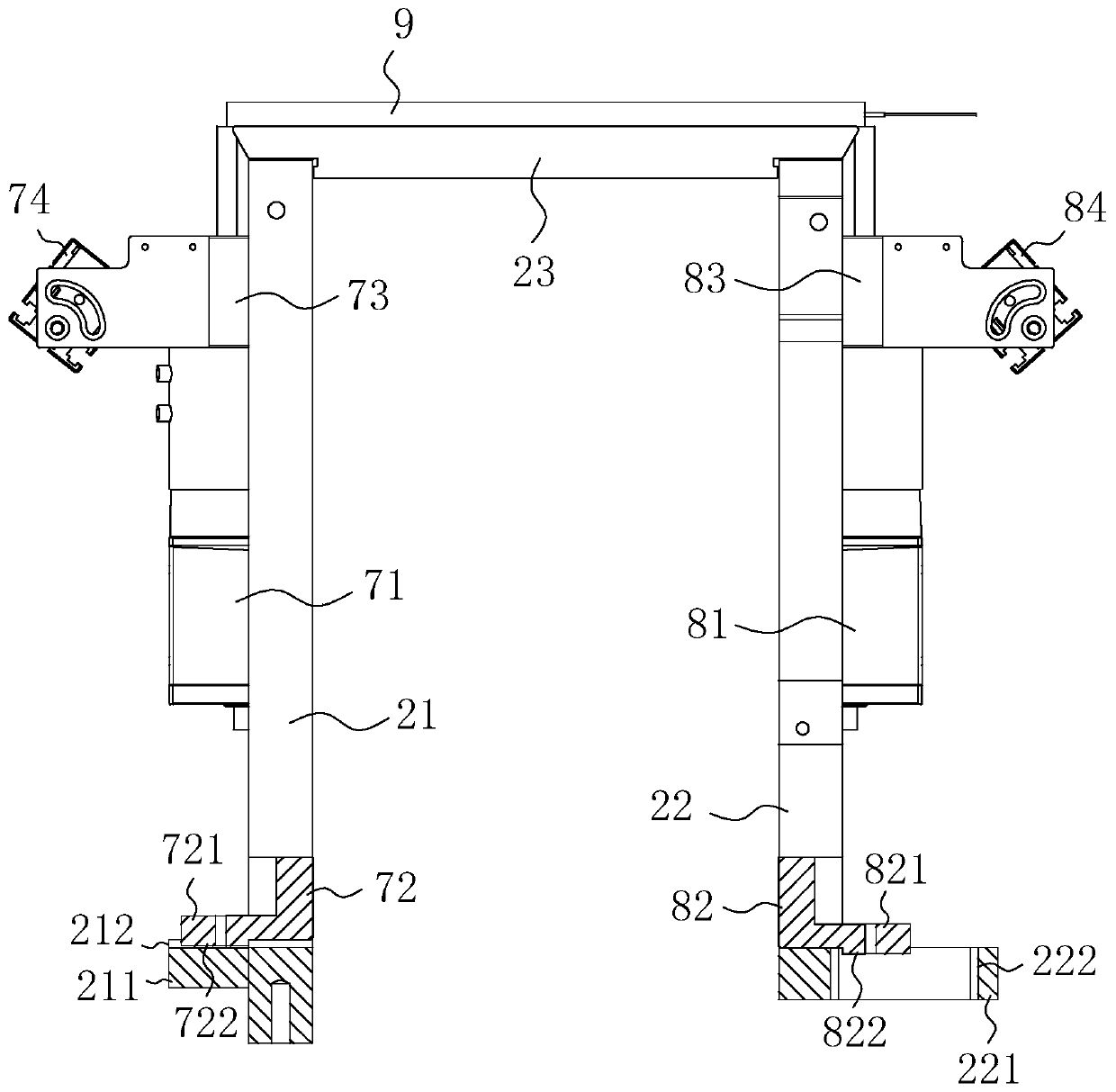

[0031] A gluing platform for measuring the thickness of the isolation film on both sides of the winding cell, refer to figure 1 , Which includes a support base, which is provided with a left camera detection assembly and a right camera detection assembly located on both sides of the support base, and a left pressing assembly and a right pressing assembly located on both sides of the support base; The camera detection component and the right camera detection component are used to detect the length of the feedback cell 9, and the left and right compression components are respectively provided with a left thickness measurement component 4 for the thickness of the feedback cell 9 And the thickness measurement component on the right 6.

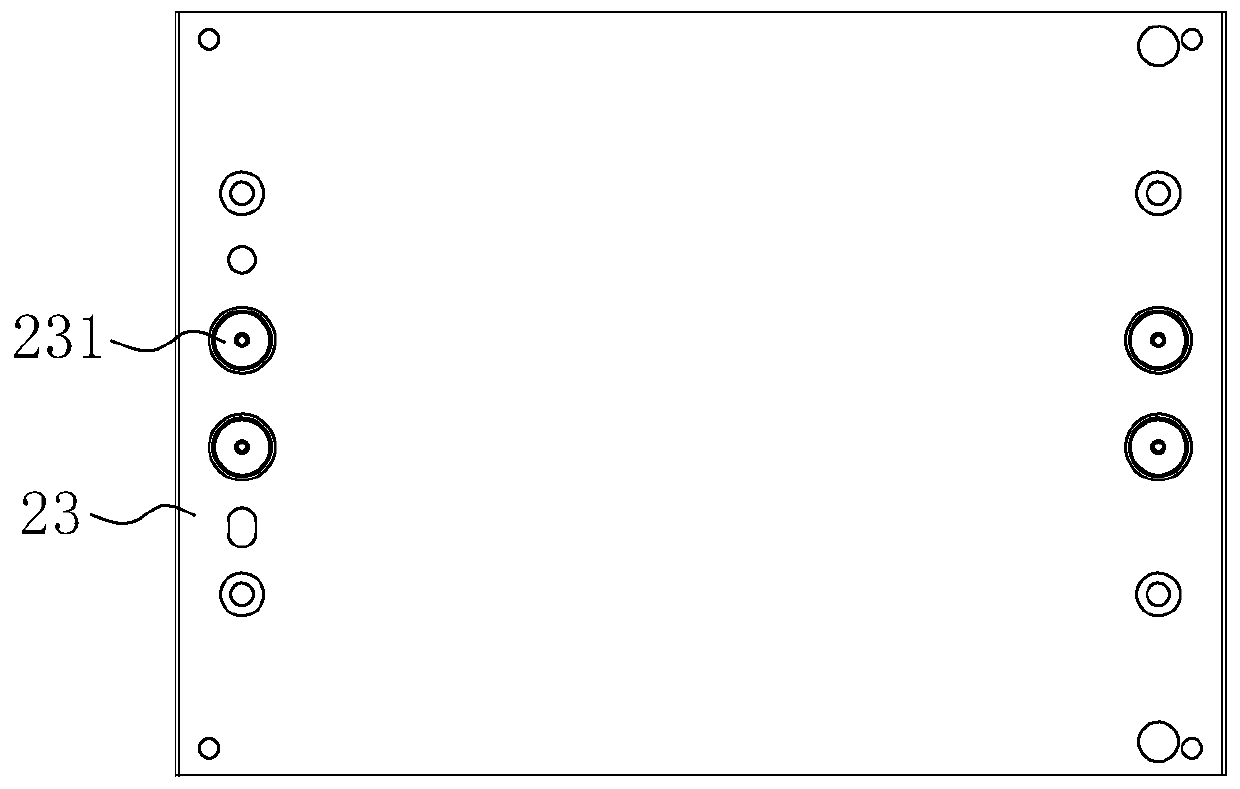

[0032] Reference figure 1 The support base includes a supporting bottom plate 1 and a supporting top plate 23. A left side supporting vertical plate 21 and a right supporting vertical plate 22 are respectively provided between the supporting bottom pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com