Automatic paint spraying device for automobile body

An automatic painting and automobile body technology, applied in the direction of spraying devices, can solve the problems of low paint mist concentration in the spray booth and uneven paint thickness of the car body, so as to achieve uniform paint thickness, avoid the decline of paint surface thickness uniformity, and improve The effect of painting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

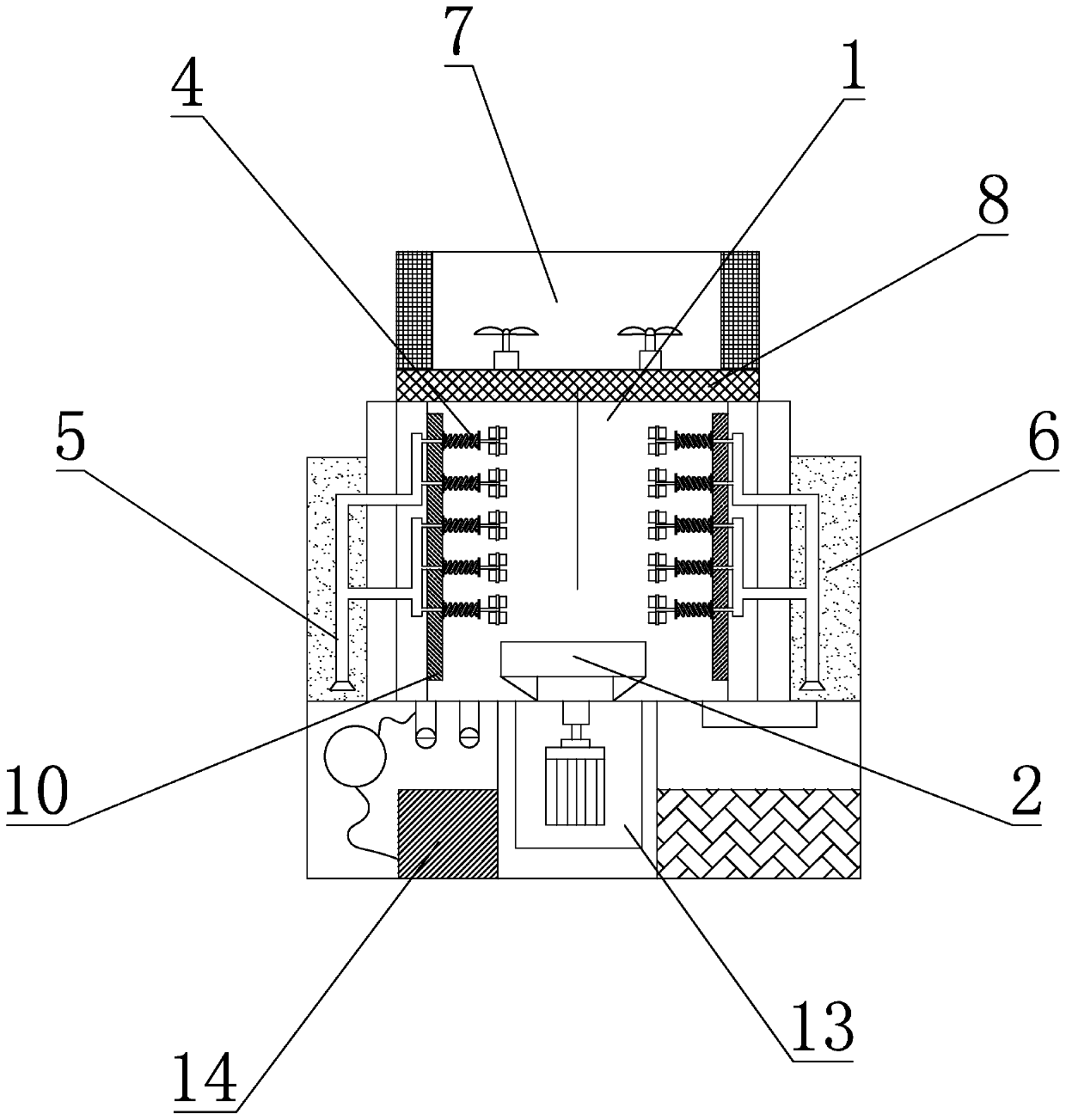

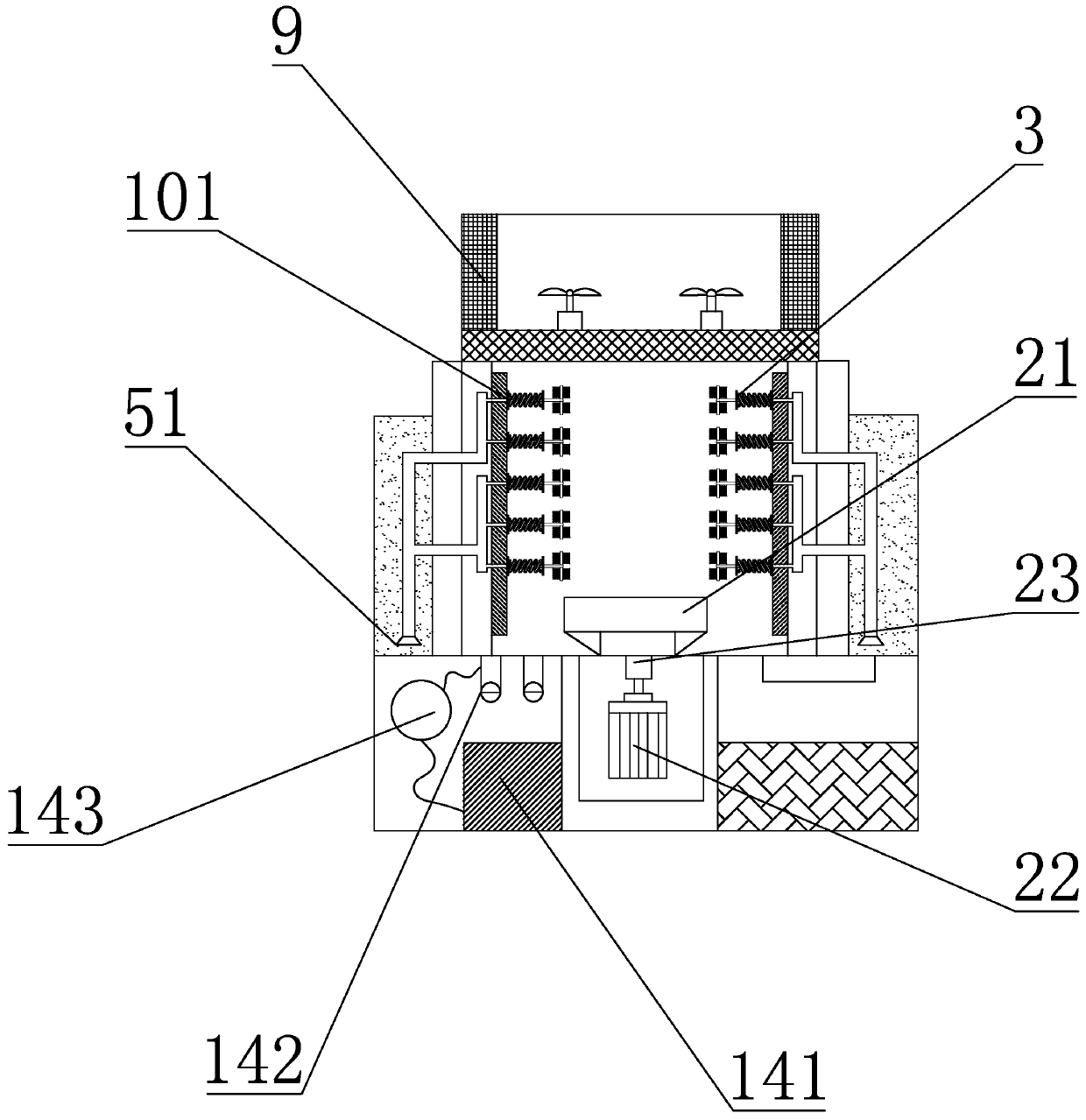

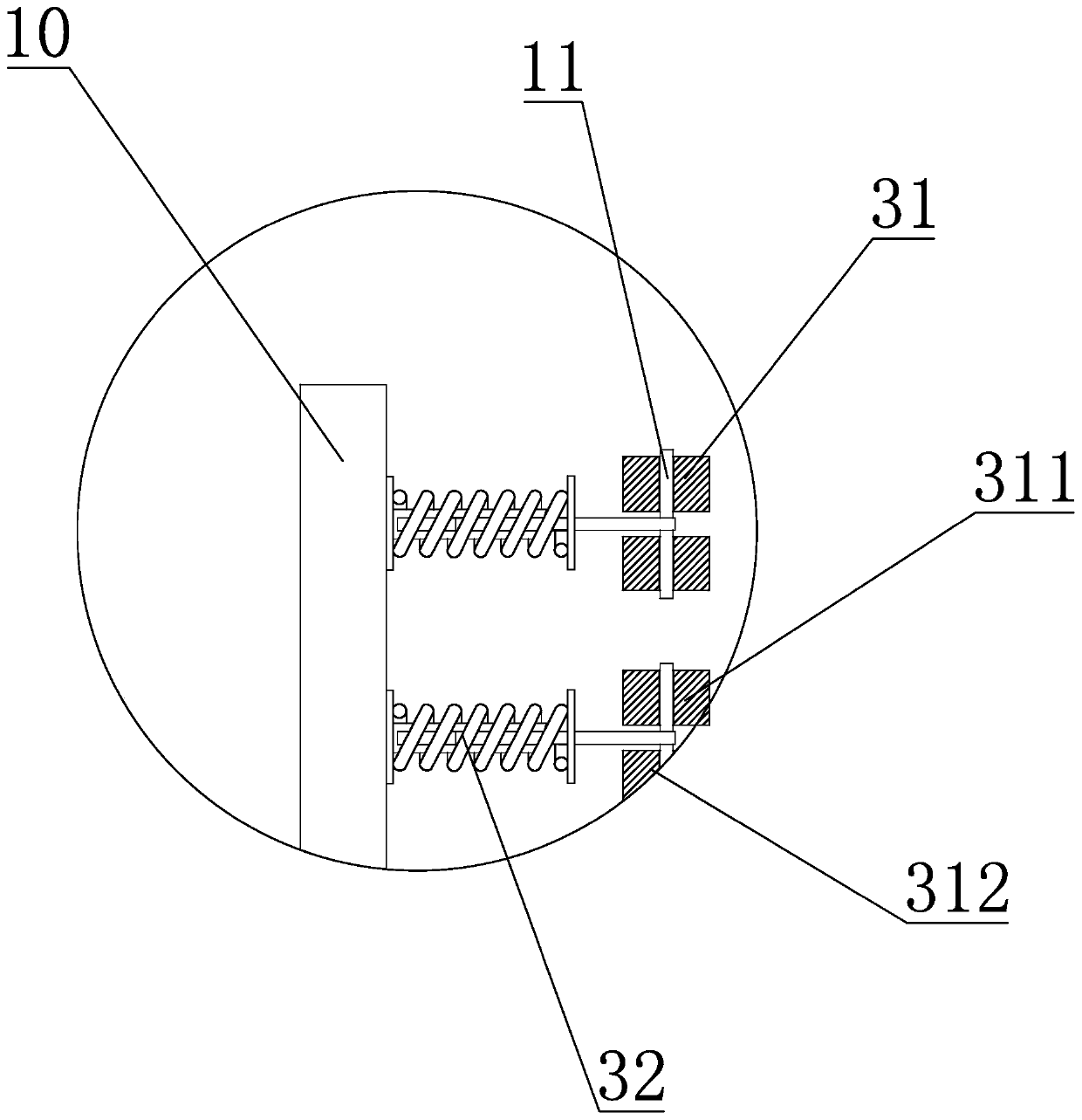

[0034] like Figure 1 to Figure 4 Shown, a kind of automatic painting device of automobile body, comprises the spray booth 1 that is used to place the vehicle to be painted, the ground of the spray booth is provided with the rotating platform 2 that drives the vehicle to be painted to rotate, and the side wall of the spray booth is provided with Several discrete painting parts 3 are connected in parallel to form a paint sprayer 4, and the painting parts are attached to the body of the vehicle to be painted during the painting process, and the side wall of the painting room is provided with a paint box connected to the painting parts through a paint delivery pipe 5 6. The upper end of the spray booth is provided with a purifier 7, the purifier and the spray booth are separated by an air filter 8, and the two ends of the purifier are provided with a catalytic converter 9; the paint sprayer is detachable from the inner wall of the spray booth through the installation plate 10 Con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com