Carbon composite material chemically modified by metal phthalocyanine complex, battery cathode material and preparation method and application thereof

A carbon composite material, metal phthalocyanine technology, applied in chemical instruments and methods, battery electrodes, organic compounds/hydrides/coordination complex catalysts, etc. It can improve the capacity and cycle life, promote the transfer of electrons, and improve the utilization rate of sulfur.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0065] 1. The preparation of a carbon composite material chemically modified by a metal phthalocyanine complex comprises the following steps:

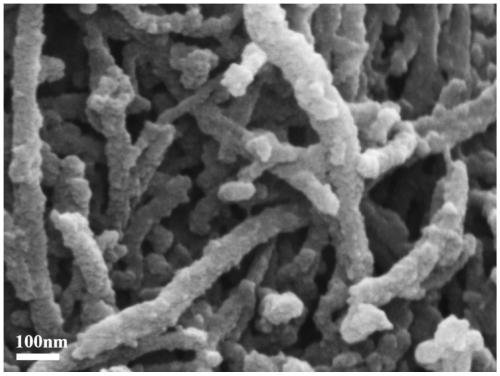

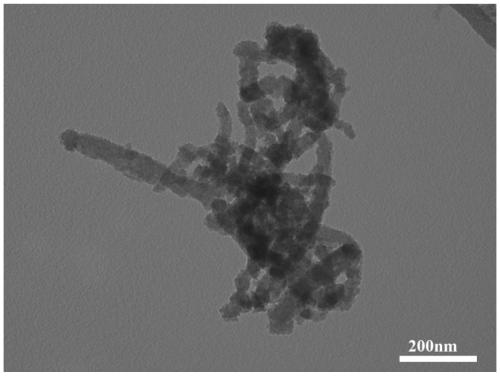

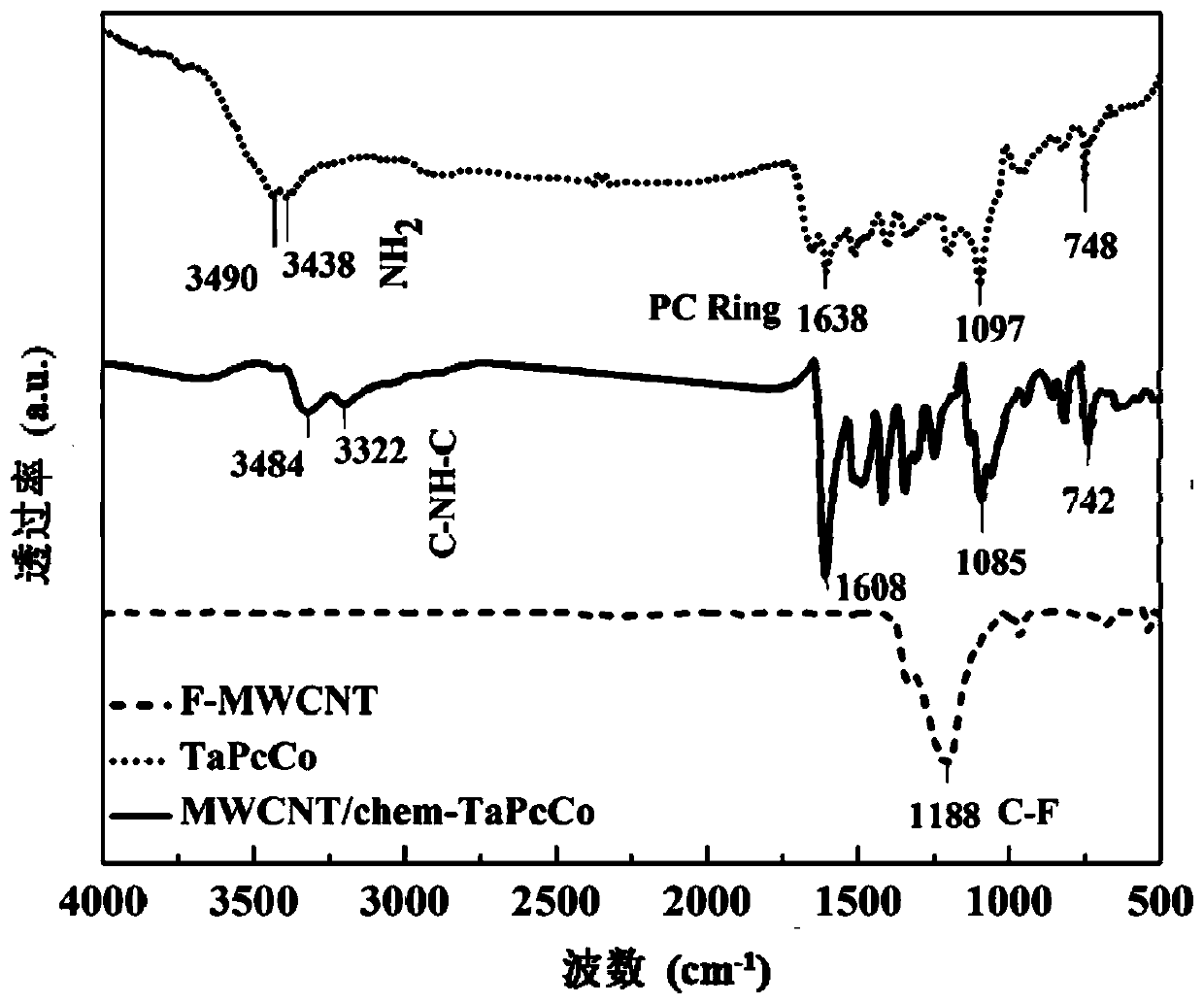

[0066] (1) Mix 1 g of fluorinated multi-walled carbon nanotubes, 2 g of cobalt tetraaminophthalocyanine, and 200 ml of dimethyl sulfoxide, and add 200 μl of pyridine dropwise under a nitrogen atmosphere, and slowly raise the temperature of the reaction system to 170 ° C. atmosphere, reflux reaction for 12h.

[0067] (2) After the reaction is completed, the obtained product is separated by filtration, and the reacted substance is washed repeatedly with dimethyl sulfoxide, N,N dimethylformamide, methanol, ethanol, and deionized water in sequence, and after freeze-drying, The solid is collected to obtain multi-walled carbon nanotubes chemically modified by cobalt tetraaminophthalocyanine.

[0068] 2. A preparation of a positive electrode material for a lithium-sulfur battery, comprising the steps of:

[0069] (3) Weigh 1.5 g of the abov...

no. 2 example

[0078] 1. The preparation of a carbon composite material chemically modified by a metal phthalocyanine complex comprises the following steps:

[0079] (1) Mix 1 g of brominated multi-walled carbon nanotubes, 2 g of nickel tetraaminophthalocyanine, and 200 ml of dimethyl sulfoxide evenly, add 200 μl of pyridine dropwise under nitrogen atmosphere, and slowly raise the temperature of the reaction system to 180 ° C, keeping nitrogen atmosphere, reflux reaction for 12 hours.

[0080] (2) After the reaction is completed, the obtained product is separated by filtration, and the reacted substance is repeatedly washed with dimethyl sulfoxide, N,N dimethylformamide, methanol, ethanol, and deionized water, and collected after freeze-drying solid, namely the multi-walled carbon nanotubes chemically modified by tetraaminophthalocyanine nickel.

[0081] 2. A preparation of a positive electrode material for a lithium-sulfur battery, comprising the steps of:

[0082](3) Weigh 1.5 g of tetra...

no. 3 example

[0089] 1. The preparation of a carbon composite material chemically modified by a metal phthalocyanine complex comprises the following steps:

[0090] (1) Mix 1g of brominated multi-walled carbon nanotubes, 2g of manganese tetraaminophthalocyanine, and 250ml of toluene evenly, add 180μl of 4-dimethylaminopyridine dropwise under a nitrogen atmosphere, and slowly raise the temperature of the reaction system to 170°C and keep Nitrogen atmosphere, reflux reaction for 12 hours.

[0091] (2) After the reaction is completed, the obtained product is separated by filtration, and the reacted substance is repeatedly washed with toluene, N,N dimethylformamide, methanol, ethanol, and deionized water, and the solid is collected after freeze-drying to obtain Carbon nanotubes chemically modified with manganese tetraaminophthalocyanine.

[0092] 2. A preparation of a positive electrode material for a lithium-sulfur battery, comprising the steps of:

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com