Rotary blade roller anti-sticking and anti-twining device based on resonance excitation and rotary cultivator with rotary blade roller anti-sticking and anti-twining device

A technology of rotary tiller roller and resonance excitation, applied in the field of rotary tiller, can solve the problems of difficulty in satisfying soil wet stickiness, congestion, increase of working resistance and energy consumption, etc. The effect of job quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

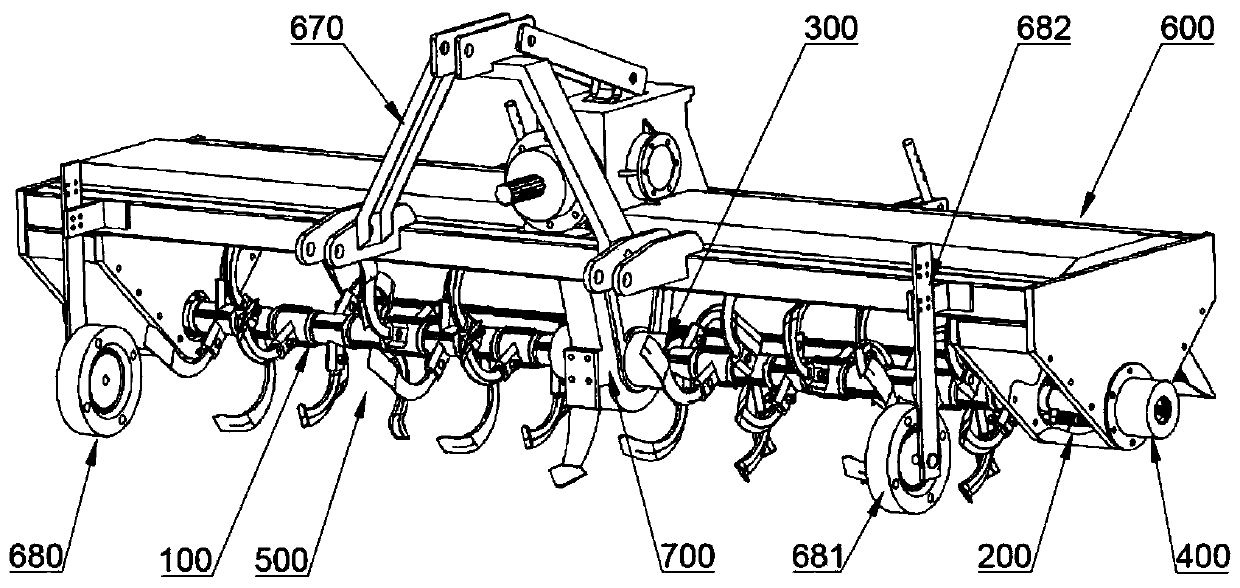

[0042] Such as Figure 1-14 As shown, the anti-sticking device of the rotary tiller roller designed in this embodiment includes the anti-sticking knife set 100, the resonance source device 200, the buffer device 300 and the resonance adjusting device 400.

[0043] Such as Figure 4~6 As shown, the anti-sticking knife set 100 is formed by connecting a plurality of scrapers 110 and a plurality of anti-wrapping knives 120 distributed on the rotary tiller roller 500, and is integrally sleeved on the knife shaft 510 of the rotary tiller roller 500. It can move along the axial direction of the cutter shaft 510.

[0044] The scraper 110 has a circular ring shape and is sleeved in the axial gap of each rotary tiller roller 500, that is, the cutter shaft 510 is between two adjacent cutter holder groups (the cutter holder group refers to the cutter holders 520 with the same rotating plane) The gap between the cutter shaft 510, or the gap between the outermost cutter seat group of the cutter ...

Embodiment 2

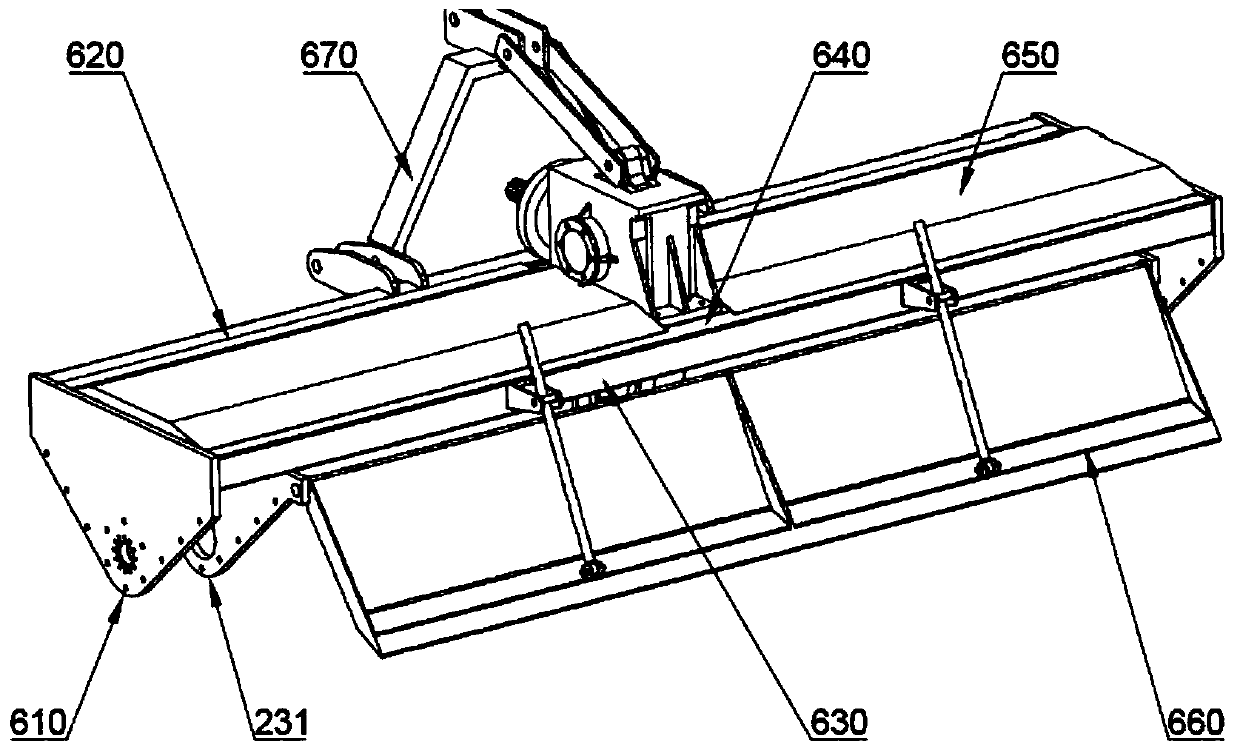

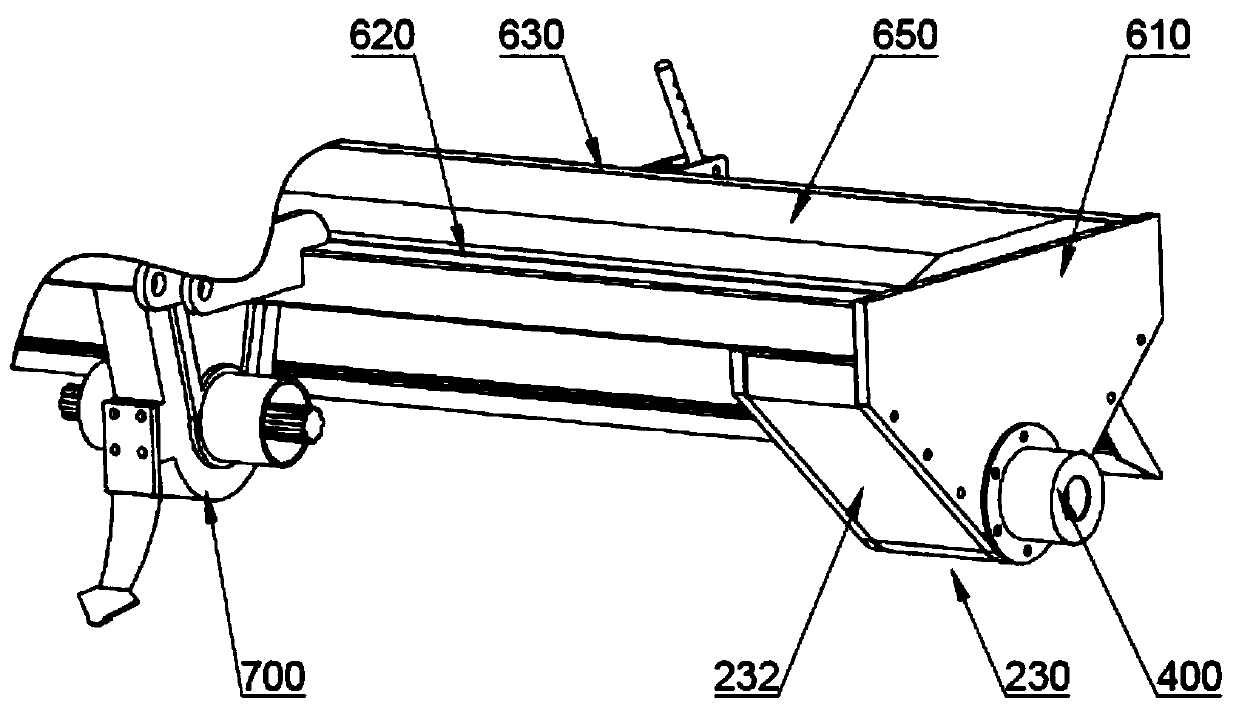

[0067] Such as Figure 1~3 As shown, this embodiment provides an intermediate transmission horizontal axis rotary tiller, which includes rotary tiller roller 500, rotary tiller frame 600, transmission device 700 and two rotary tiller rollers designed in Embodiment 1. Sticking device.

[0068] The rotary tiller roller 500 includes a knife shaft 510, a knife seat 520 and a rotary tiller 530. Among them, the cutter shaft 510 is lengthened on the original basis to install the resonance source device 200 and the buffer device 300. The transmission end of the cutter shaft 510 is fixedly connected to the power output shaft of the transmission device 700, and the supporting end is connected to the frame side plate 610 by means of a bearing cover combination screwed to the inner surface of the frame side plate 610. Two tool holders 520 with an included angle of 120°~160° are fixed on the same tool shaft 510, and a set of rotary tillers 530 are fixed to the two tool holders 520 by bolts,...

Embodiment 3

[0078] This embodiment provides a lateral-axis rotary cultivator with lateral transmission. Only one rotary cultivator roller anti-sticking device is installed. The buffer device 300 of the rotary cultivator roller anti-sticking device is installed on the cutter shaft 510 and the transmission At one end of the device 700 connected, the resonance source device 200 of the anti-sticking device of the rotary cutter roller is installed on the end of the cutter shaft 510 away from the transmission device 700.

[0079] The rest of the structure and operation process refer to the horizontal axis rotary tiller with intermediate transmission.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com