A configurable high-speed parallel detection method, system and medium for motor speed and position

A technology of speed detection and detection method, which is applied in the direction of control system, control generator, vector control system, etc. It can solve the problems of affecting the acquisition rate, different sensor components, and increase in the number of sensors, so as to achieve high-speed data exchange and expand the detection range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

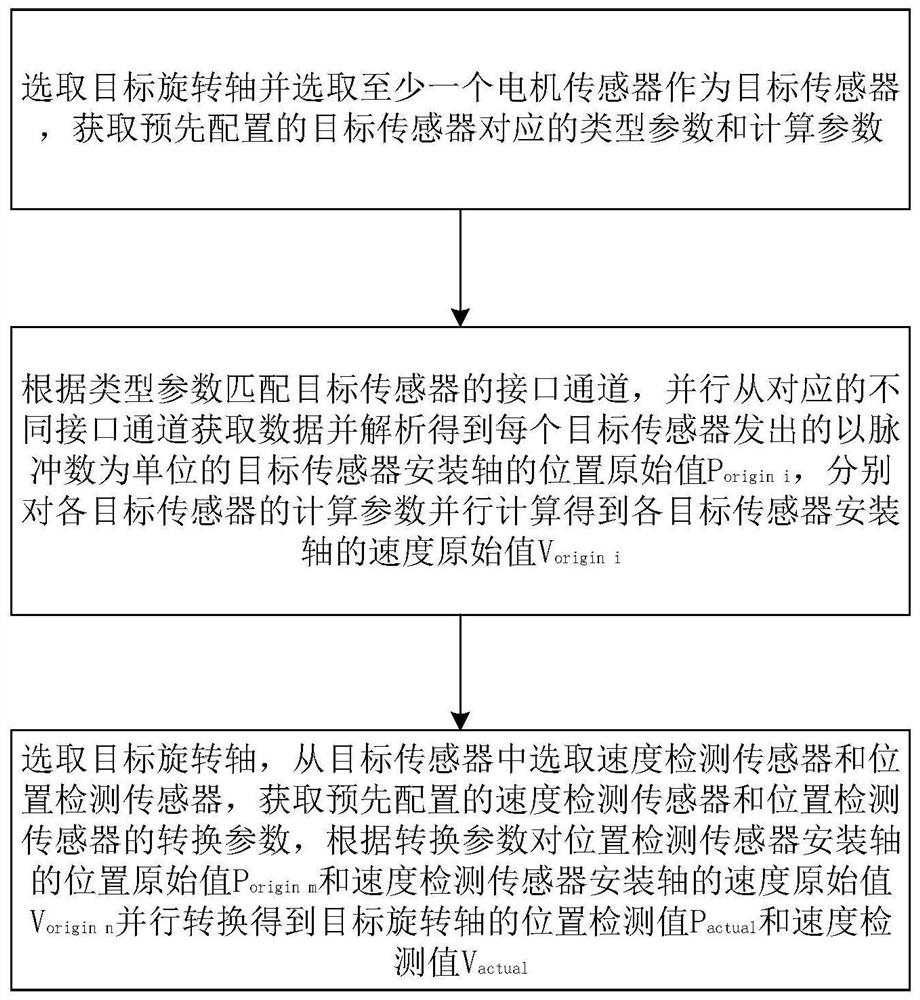

[0044] Such as figure 1 As shown, the configurable motor speed position high-speed parallel detection method of the present invention comprises the following steps:

[0045] 1) Select at least one motor sensor as the target sensor, and obtain the type parameters and calculation parameters corresponding to the pre-configured target sensor;

[0046] 2) Match the interface channel of the target sensor according to the type parameter, obtain data from different corresponding interface channels in parallel and analyze to obtain the original value P of the position of the target sensor installation axis sent by each target sensor in units of pulse number origin i , the calculation parameters of each target sensor are calculated in parallel to obtain the original velo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com