Piezoelectric device and manufacturing method thereof, electronic device and control method

A technology for piezoelectric devices and electronic devices, which is applied in the field of piezoelectric devices and can solve the problems of being unable to form bendable piezoelectric devices and not being bendable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

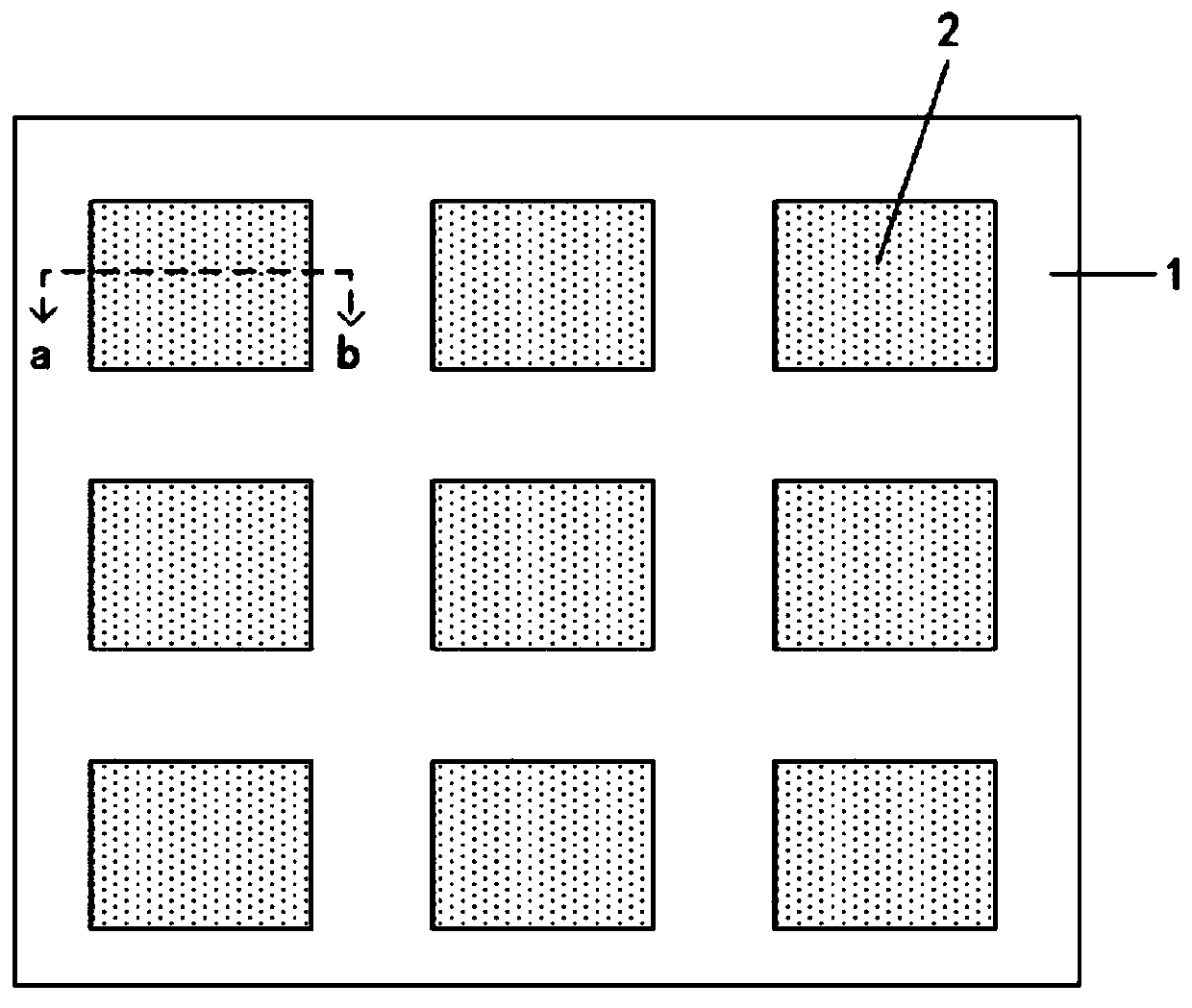

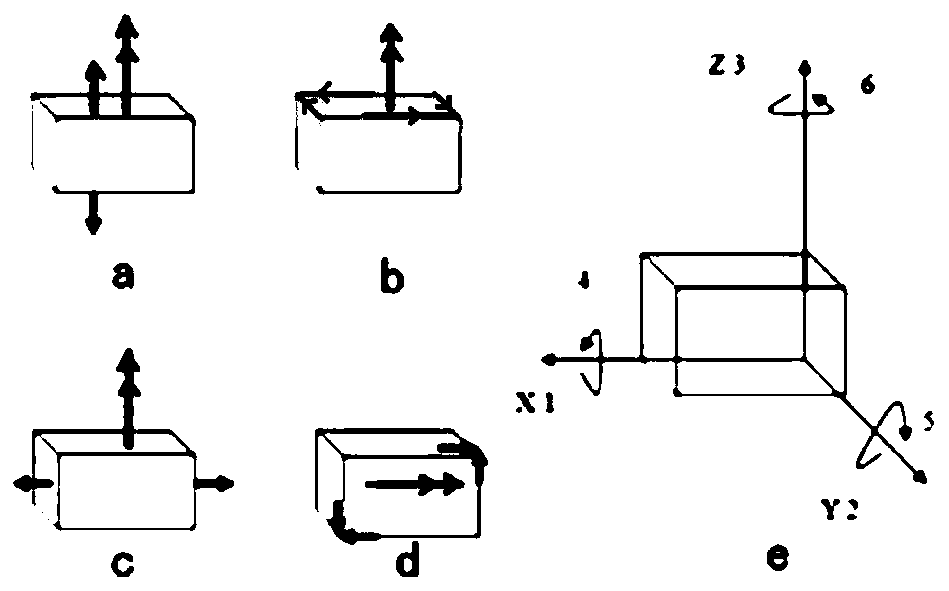

[0059] An embodiment of the present invention provides a piezoelectric device, referring to figure 1 As shown, the piezoelectric device includes: a flexible substrate 1 and a plurality of piezoelectric units 2 disposed on the flexible substrate 1 and arranged in an array. refer to figure 2 As shown, each piezoelectric unit 2 includes: a first electrode 21 , a piezoelectric part 20 and a second electrode 22 sequentially stacked on the flexible substrate 1 ; the material of the piezoelectric part is a rigid material.

[0060] The material of the flexible substrate is not limited here. For example, the material of the flexible substrate can be PI (Polyimide, polyimide), PET (Polyethylene Terephthalate, polyethylene terephthalate) or PDMS (Polydimethylsiloxane ,Polydimethylsiloxane).

[0061] The above-mentioned first electrode may only include one electrode layer, and the material of the electrode layer may be a single metal or multiple metals. Exemplarily, the material of th...

Embodiment 2

[0085] An embodiment of the present invention provides an electronic device, including: a plurality of switch units and the above-mentioned piezoelectric device; the plurality of switch units are electrically connected to the plurality of piezoelectric units of the piezoelectric device in one-to-one correspondence, and are configured to control the piezoelectric unit voltage.

[0086] The specific structure of the switch unit is not limited here. Figure 7 In FIG. 1 , a switching unit including a thin film transistor (ThinFilm Transistor, TFT) is taken as an example for illustration. Figure 7 Among them, a plurality of thin film transistors 3 are electrically connected to a plurality of piezoelectric units 2 of the piezoelectric device in a one-to-one correspondence. refer to Figure 8 As shown, the piezoelectric unit 2 in the piezoelectric device can be bound to the PI film 4 (that is, the PI-TFT backplane) provided with a plurality of TFT3 through the binding layer 5 (Bon...

Embodiment 3

[0101] An embodiment of the present invention provides a method for manufacturing a piezoelectric device as described in Embodiment 1, the method comprising:

[0102] S01. Fabricate a first substrate; the first substrate includes a flexible substrate and a plurality of first electrodes disposed on the flexible substrate.

[0103] S02 , making a second substrate; the second substrate includes a rigid substrate, and a plurality of piezoelectric parts and a plurality of second electrodes sequentially stacked on the rigid substrate; the material of the piezoelectric part is a rigid material.

[0104] S03 , peeling off the plurality of piezoelectric parts and the plurality of second electrodes of the second substrate.

[0105] For example, laser peeling and other methods can be used for peeling.

[0106] S04 , binding the stripped multiple piezoelectric parts and multiple second electrodes to the first substrate to obtain multiple piezoelectric units arranged in an array.

[0107...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie temperature | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com