Full-automatic adjustable and portable optical cable stripping device

An adjustable and portable technology, applied in the direction of light guide, optics, instruments, etc., can solve the problems of personal safety hazards, labor, and time-consuming process of optical cable stripping, so as not to waste material resources, meet the needs of stripping, and avoid direct contact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

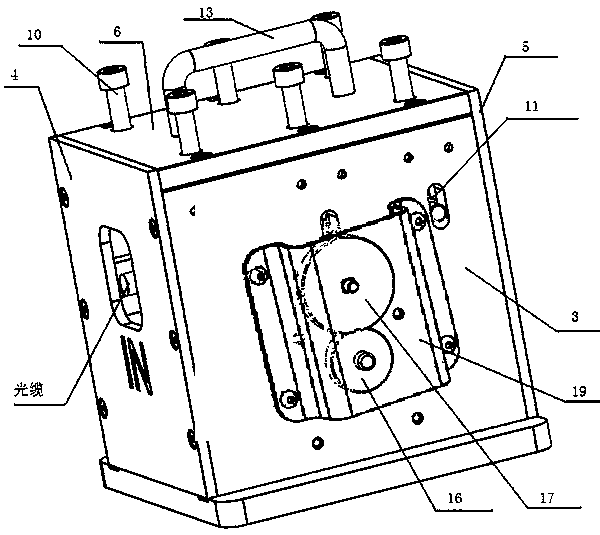

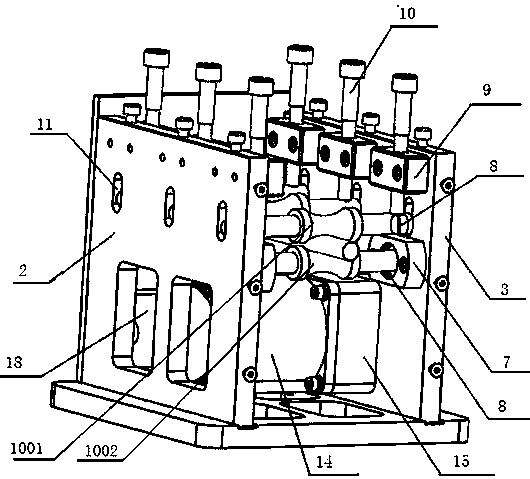

[0032] The invention relates to the field of optical fiber and cable tools, and mainly aims to solve the problems of time-consuming, laborious and certain personal safety hazards in the traditional process of stripping optical cables. This embodiment discloses a specific embodiment of a fully automatic adjustable portable optical cable stripper. The optical cable stripper mainly includes a base 1, a left cover 2 and a right cover 3 fixed to the base 1, and a on the drive mechanism.

[0033] There are 3 roller sets rotatably connected between the left cover plate 2 and the right cover plate 3 above the driving mechanism. Note: the present invention is not limited to 3 roller sets, but can be 4 roller sets or 5 roller sets Group. The three roller groups are arranged in parallel between the left cover plate 2 and the right cover plate 3. The roller group includes two rollers arranged symmetrically up and down. Thick middle thin roller structure. In this embodiment, the 3 rolle...

Embodiment approach 2

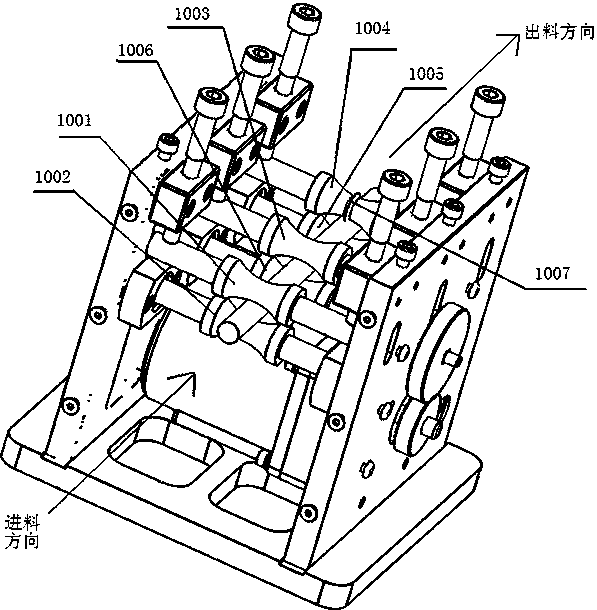

[0042] This embodiment is a further optimization of Embodiment 1, and the specific optimization solution is: the rollers located above the roller group in Embodiment 1 are arranged in a structure that can be adjusted up and down in height. That is, on the left cover 2 and the right cover 3, the positions corresponding to the two ends of the rollers (the first driven roller 1001, the third driven roller 1003, and the fourth driven roller 1004) located above the roller group Offer vertical strip groove 11, on the first driven roller 1001, the 3rd driven roller 1003, height adjusting device is set on the 4th driven roller 1004, the first driven roller 1001, the 3rd driven roller Both ends of the driving roller 1003 and the fourth driven roller 1004 slide up and down in the bar-shaped groove 1004 through the height adjusting device.

[0043] The height adjusting device includes a plurality of bolt bearing seats 9 fixed on the left cover plate 2 and the right cover plate 3 and bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com