Bottom lifting frame and hydraulic support

A technology of hydraulic support and bottom frame, which is applied to mine roof support, mining equipment, earthwork drilling, etc., can solve problems such as affecting the operation of hydraulic support and falling off of pins, and achieves the effect of simple structure, avoiding failure and saving cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

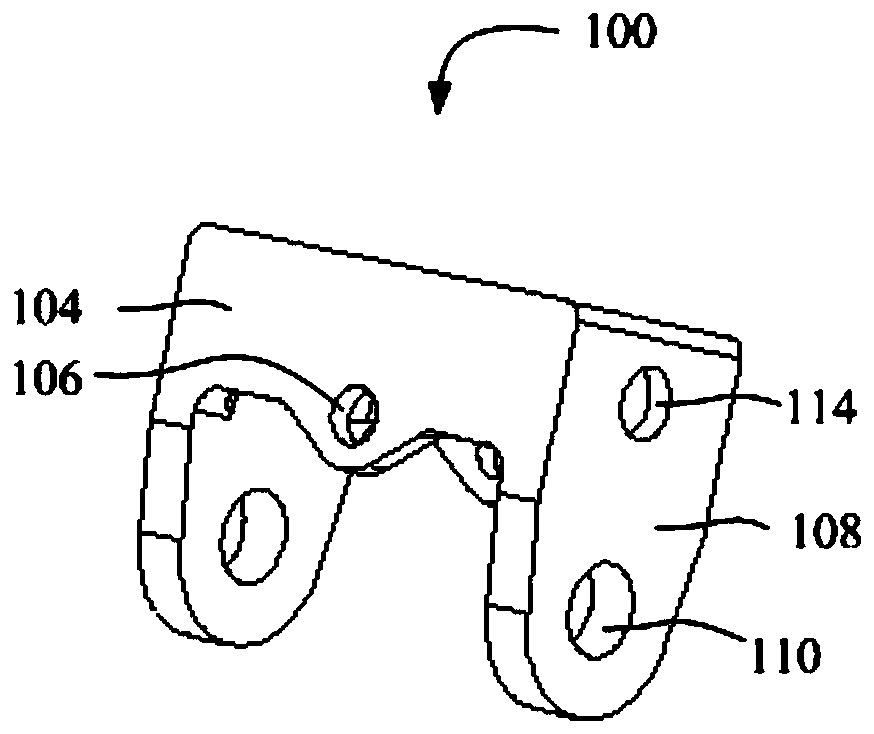

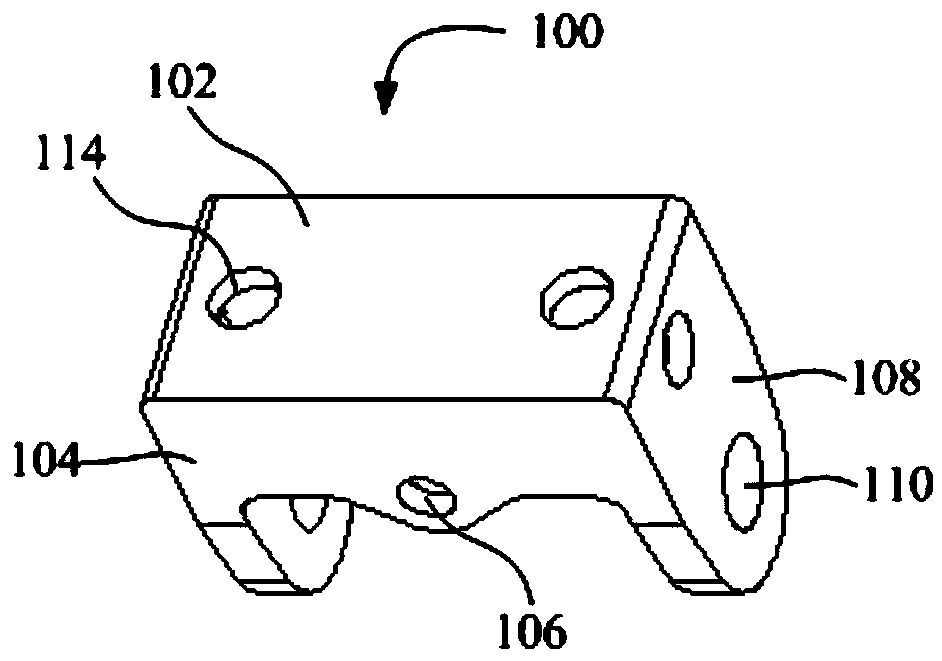

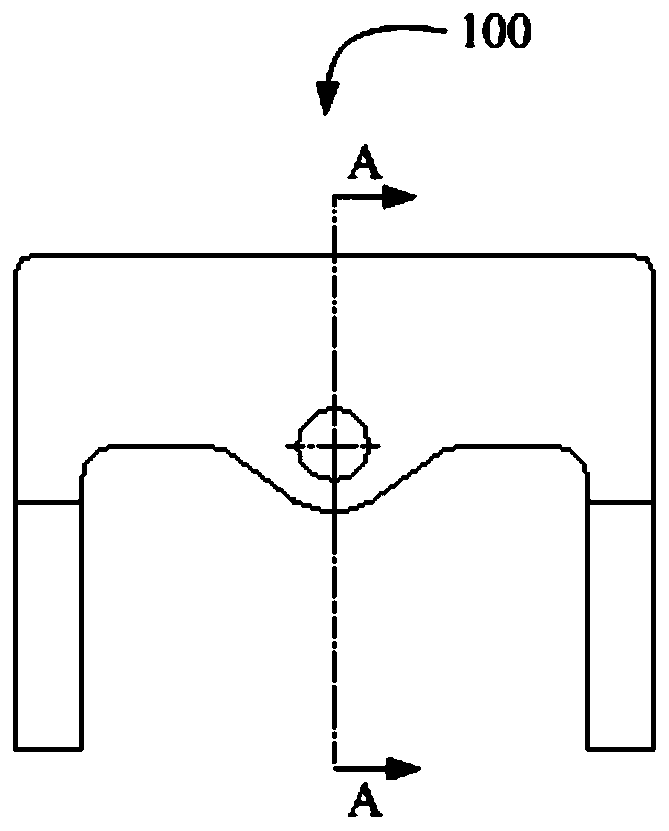

[0044] like Figure 1 to Figure 5 As shown, a bottom lift frame 100 proposed by the first embodiment of the present invention includes: a top plate 102 , a side plate 104 and an ear plate 108 .

[0045] The lower surface of the top plate 102 is provided with a first arc structure 112; the side plate 104 is connected to the top plate 102 and is located on both sides of the top plate 102, and the side plate 104 is provided with a first pin hole 106; the ear plate 108 is connected to the top plate 102, located in On both sides of the top plate 102 , the ear plate 108 and the side plate 104 are arranged around the periphery of the top plate 102 , and the ear plate 108 is provided with a second pin hole 110 ; wherein, the bottom lifting frame 100 is configured as an integral structure.

[0046] The bottom-lifting frame 100 provided in this embodiment, by setting the top plate 102, the side plate 104 and the ear plate 108 as an integrated structure, avoids failures caused by the wel...

Embodiment 2

[0049] like figure 1 As shown, in the above embodiment, further, the bottom lifting frame 100 further includes a hoisting hole 114 . The hoisting hole 114 is provided on the ear plate 108 .

[0050] In this embodiment, the hoisting holes 114 are provided on the lugs 108, and are directly hoisted and used when installing the bottom-lifting frame 100, thereby reducing the use of materials such as hoisting ring seats and hoisting rings, and reducing costs.

[0051] Further, as figure 2 As shown, the hoisting holes 114 are also provided on the top plate 102 .

[0052] In this embodiment, the hoisting holes 114 are provided on the side panel 104 and the top panel 102 at the same time, which facilitates manual operation and also reduces the weight of the bottom lifting frame 100 .

Embodiment 3

[0054] like Image 6 As shown, a hydraulic support provided by a third embodiment of the present invention includes a bottom-lifting mechanism 200 and a bottom-lifting frame 100 as in any of the above-mentioned embodiments.

[0055] The bottom lifting mechanism 200 includes a bottom lifting jack 202 hinged to the bottom lifting frame 100 , the bottom lifting frame 100 is located above the bottom lifting mechanism 200 , and the bottom lifting frame 100 is hinged to the bottom lifting mechanism 200 .

[0056] In this embodiment, since the hydraulic support includes the bottom lifting frame 100 in any of the above embodiments, the hydraulic support has all the beneficial effects of the bottom lifting jack 202 in any of the above embodiments, and further improves the service life of the hydraulic support . The bottom lifting jack 202 is hinged with the bottom lifting frame 100 . The bottom lifting frame 100 is located above the bottom lifting mechanism 200 and is hingedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com