Water-saving blast furnace cooling wall structure with multiple layers of water supply pipes and application process thereof

A technology of cooling wall and water supply pipe, applied in the direction of cooling device, etc., can solve the problems affecting the safe production and longevity of blast furnace, the furnace shell is heated and deformed, the output is reduced and the consumption is increased, so as to achieve a safe and reliable supply guarantee, reduce water leakage, improve The effect of processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the present invention, it should be understood that the terms "length", "width", "upper", "lower", "front", "rear", "left", "right", "vertical", "horizontal" ", "Top", "Bottom", "Inner", "Outer", "Clockwise", "Counterclockwise", "Axial", "Plane Direction", "Circumferential" and other indications are based on The orientation or positional relationship shown in the drawings is only for the convenience of describing the present invention and simplifying the description, and does not indicate or imply that the referred device or element must have a specific orientation, be constructed and operated in a specific orientation, and therefore cannot be understood as Limitations on the Invention.

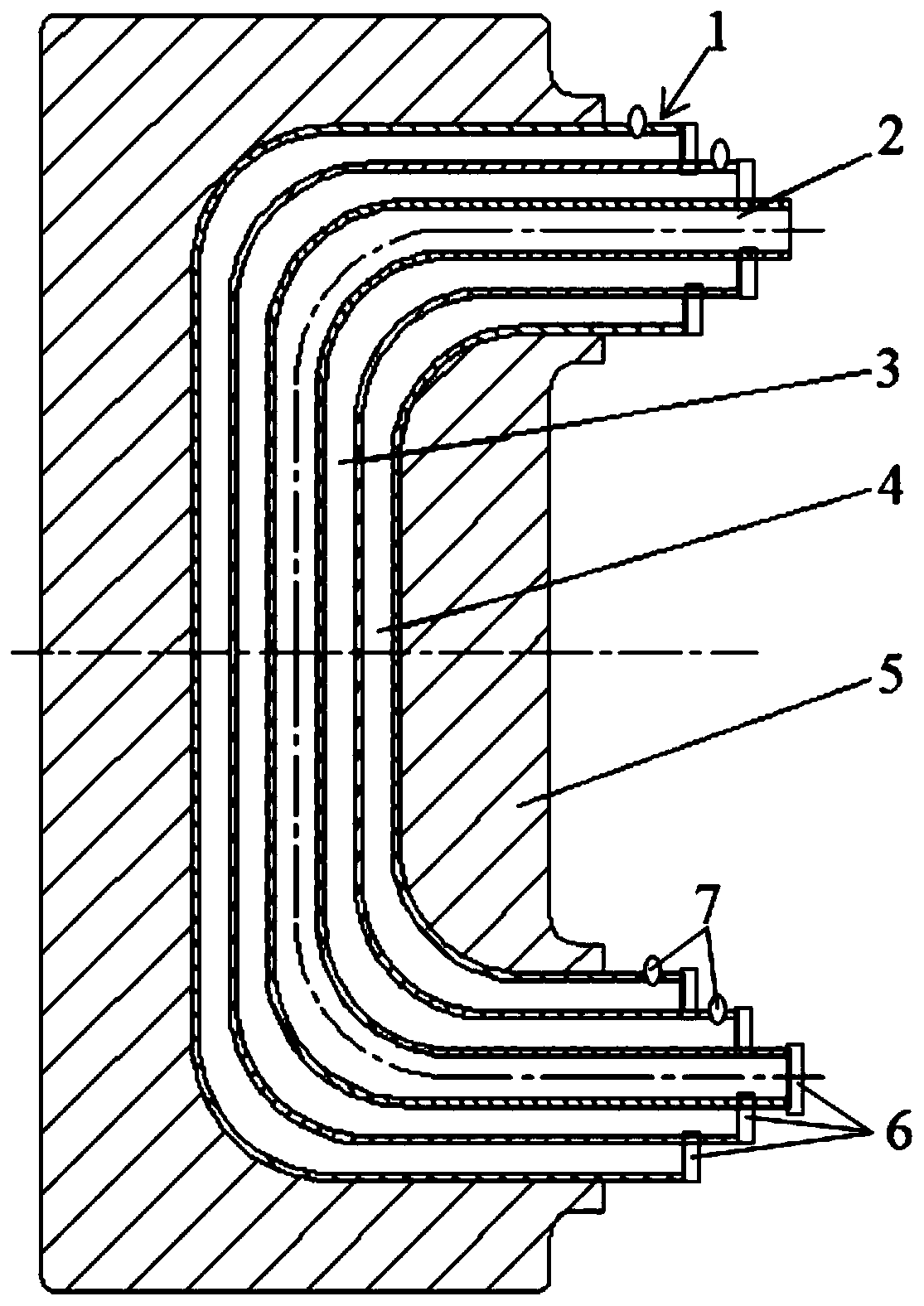

[0029] like figure 1 As shown, a water-saving multi-layer water supply tube blast furnace stave structure includes a furnace shell, a refractory lining and a cooling stave 5, the stave 5 is located between the furnace shell and the refractory lining, and cooling water pipes are arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com