Preparation method of large-size rotary ceramic target material

A ceramic target, large-scale technology, applied in the field of large-scale rotating ceramic target preparation, can solve problems such as excessive straightness deviation of the target, tilting of the target's center of gravity, and different temperature and pressure resistance performance of the furnace bottom. Modulus of elasticity and flexural strength, effect against deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

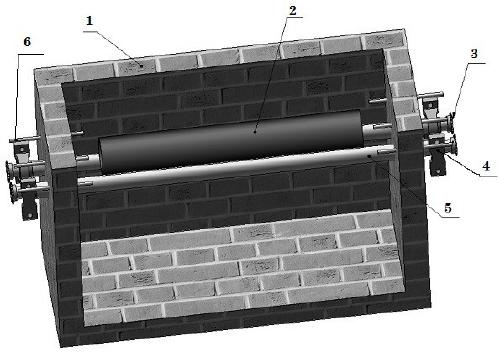

[0028] Attached below figure 1 And embodiment the present invention is described in further detail:

[0029] A method for preparing a large-size rotating ceramic target, figure 1 It is a schematic diagram of the method, mainly a schematic diagram of the internal structure of the sintering furnace and the sintering furnace; it specifically includes the following steps:

[0030] 1) To make the green body of the target material, the raw material of the green body of the target material is selected to be spherical particles that are sprayed and granulated with a sufficient amount of binder to ensure the uniformity and strength of the green body during molding;

[0031] 2) Forming mold, using the structure of inner cylinder steel core and outer cylinder rubber sleeve;

[0032] 3) The target body is degreased, and the target body is placed in a sintering furnace in a vertical position, and the degreasing temperature is maintained at 600 degrees Celsius for 10 hours;

[0033] 4) P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com