Mobile phone lens bracket group chamfer electrolytic machining fixture and technology method thereof

A lens and bracket technology, which is applied in the field of electrolytic processing jigs for group chamfering of mobile phone lens brackets, can solve the problem of not meeting the requirements of high-volume, high-efficiency mobile phone lens bracket chamfering processing, long time-consuming workpieces, and heavy labor workload and other problems, to achieve the effect of low labor intensity, less processing time, and saving time for changing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

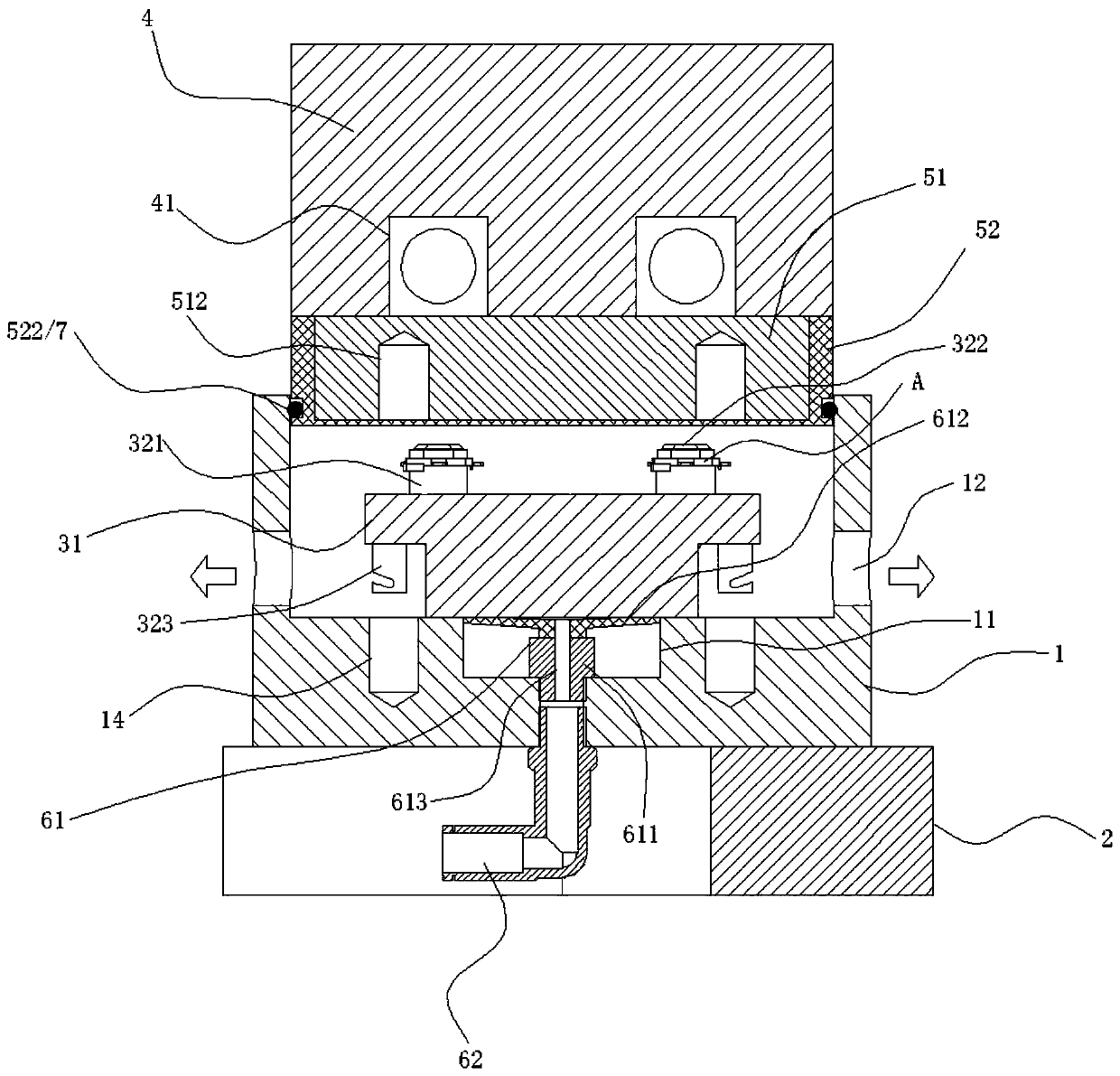

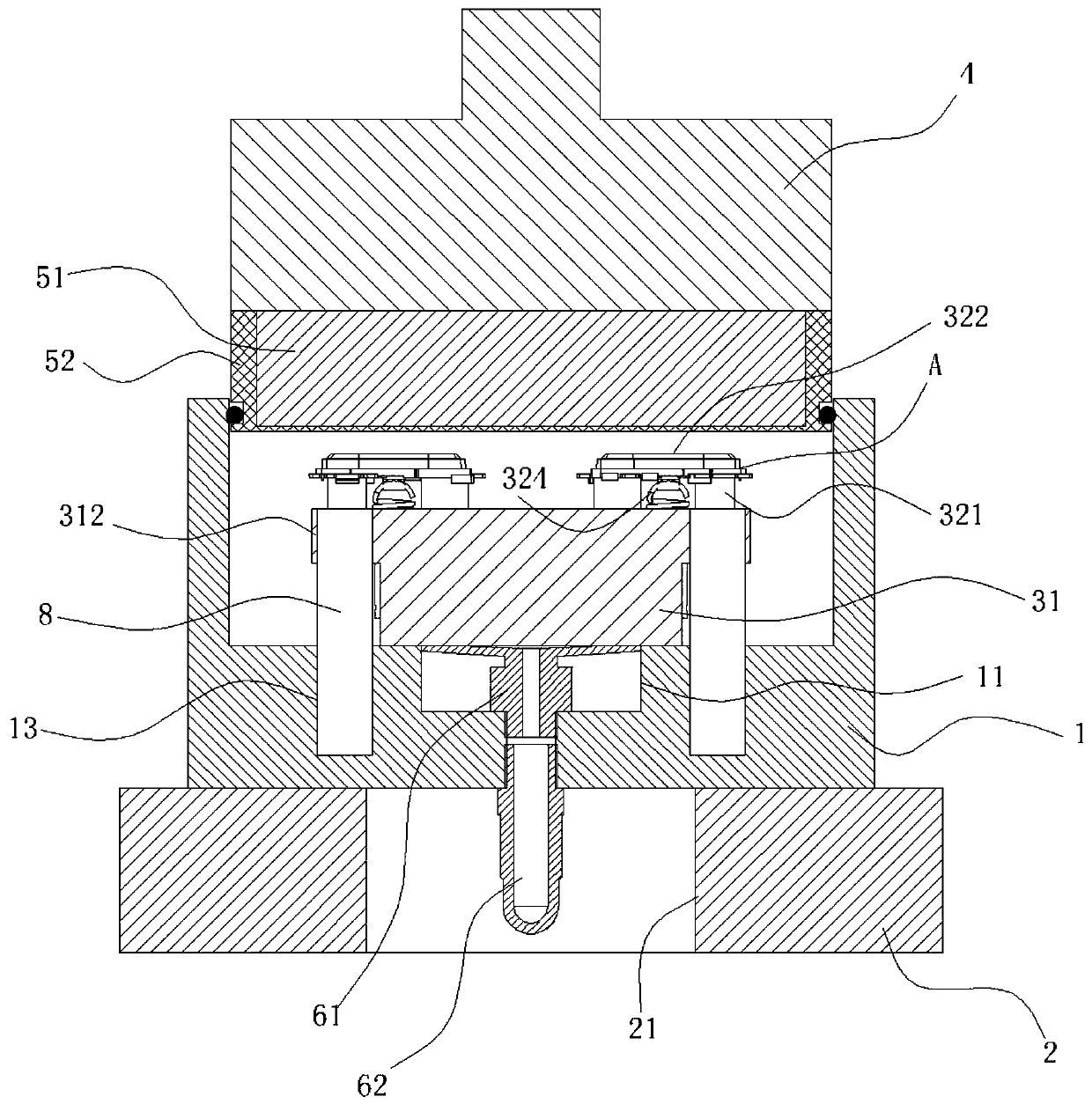

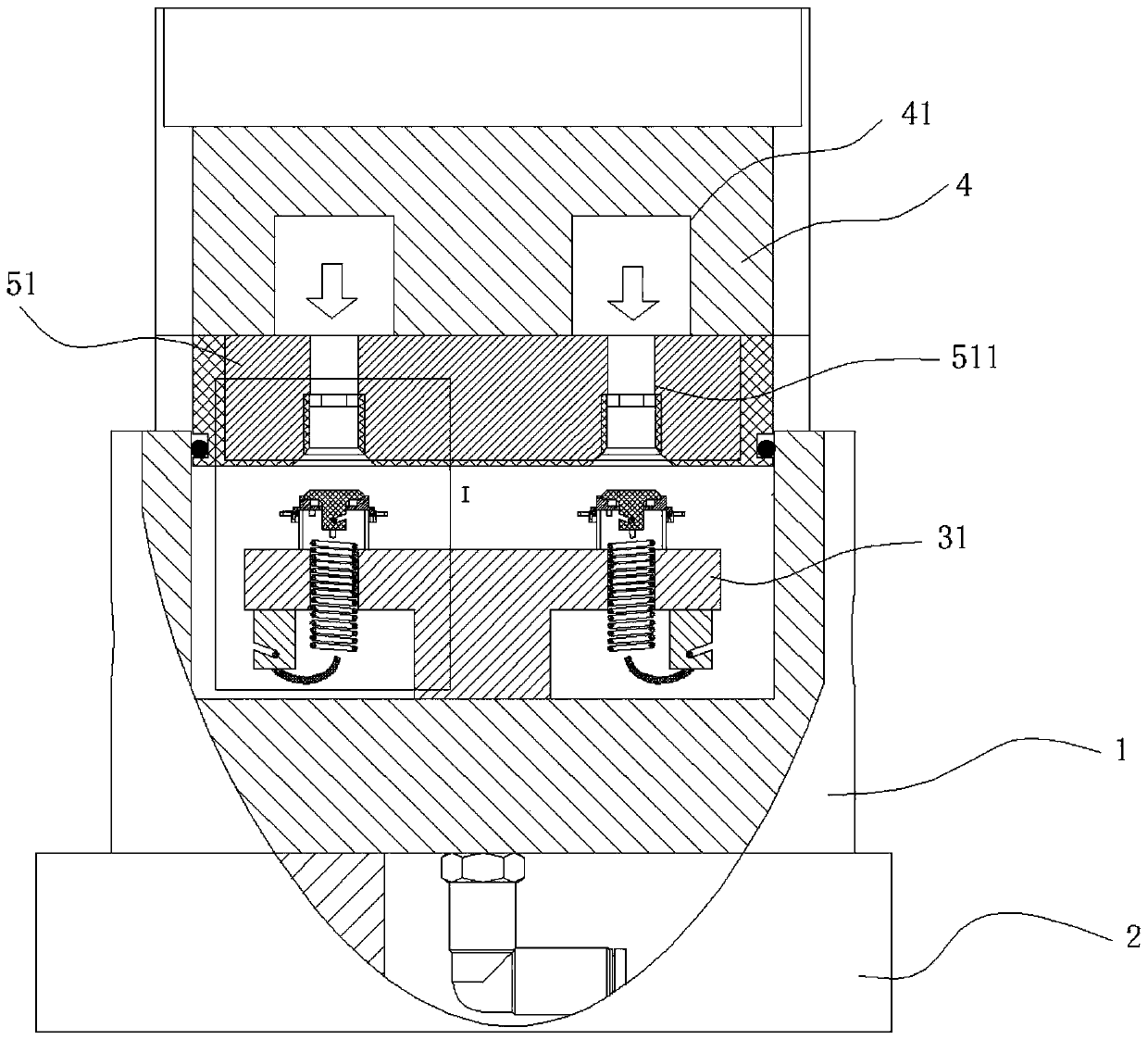

[0036] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

[0037] Such as Figure 1-3b As shown, the present invention provides a mobile phone lens bracket group chamfering electrolytic machining fixture, which is used for chamfering the top edge of the mobile phone lens bracket, including a back pressure cover 1, a base 2, a workpiece positioning block, and a spindle connecting rod 4 and the cathode assembly.

[0038] The back pressure cover 1 is a container with a cover bottom and side walls and an open upper end.

[0039] The back pressure cover 1 is fixed on the base 2, and the base 2 can be fixedly arranged on the machine tool. During electrolytic machining, the fixture is set on the machine tool to complete the machining.

[0040] The workpiece positioning block includes a positioning block body 31 and four sets of fixing components.

[0041] The positioning block body 31 is detachably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com