Inner arc type variable cross-section L-shaped terminal electrical testing fixture

A variable cross-section and terminal technology, applied in the field of inner arc variable cross-section L-shaped terminal electrical measuring jig, can solve the problems of limited miniaturization design, poor reliability of test results, terminal breakage, etc., to save R&D cycle and R&D cost , optimize the internal stress distribution, avoid the effect of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

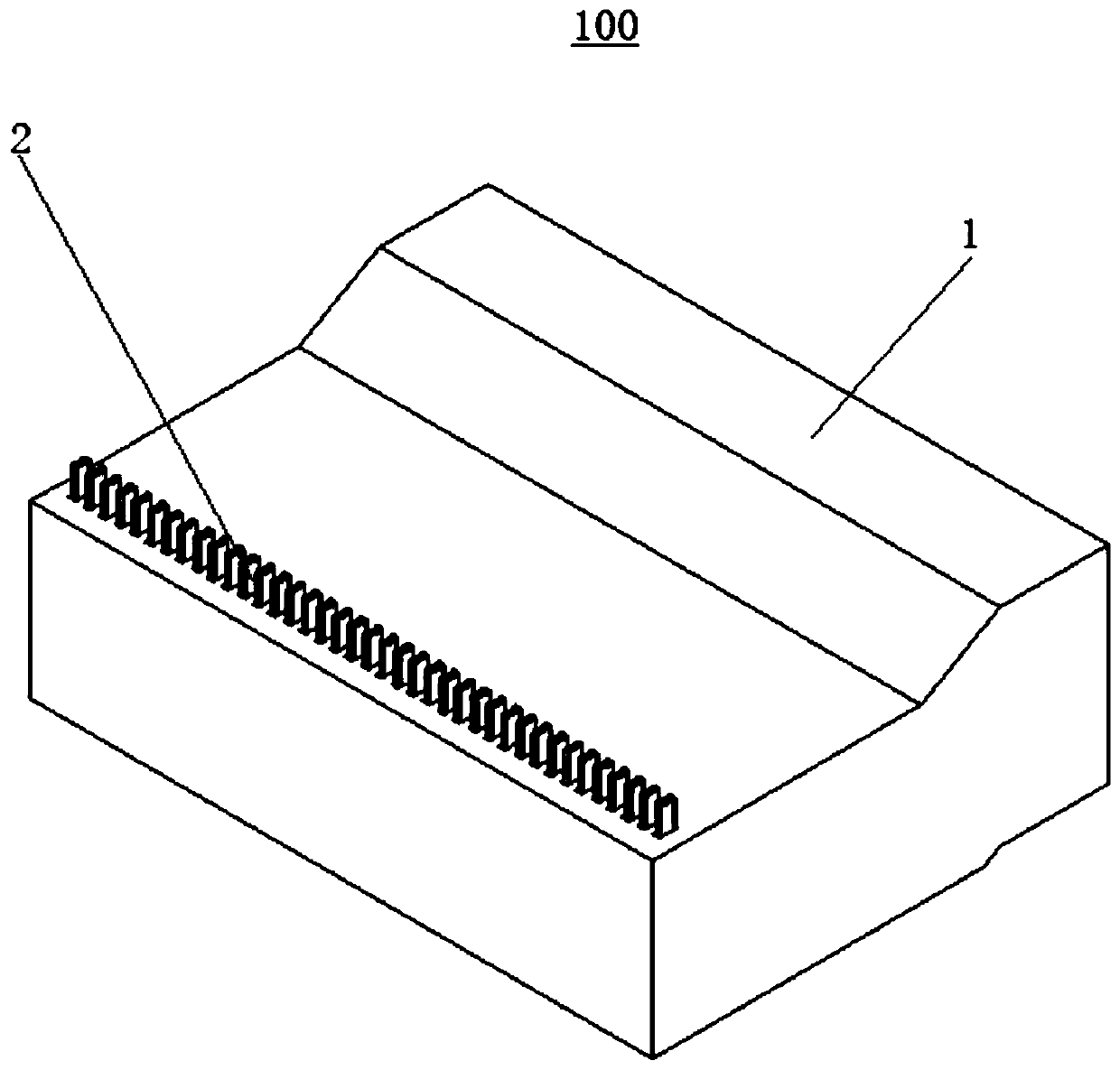

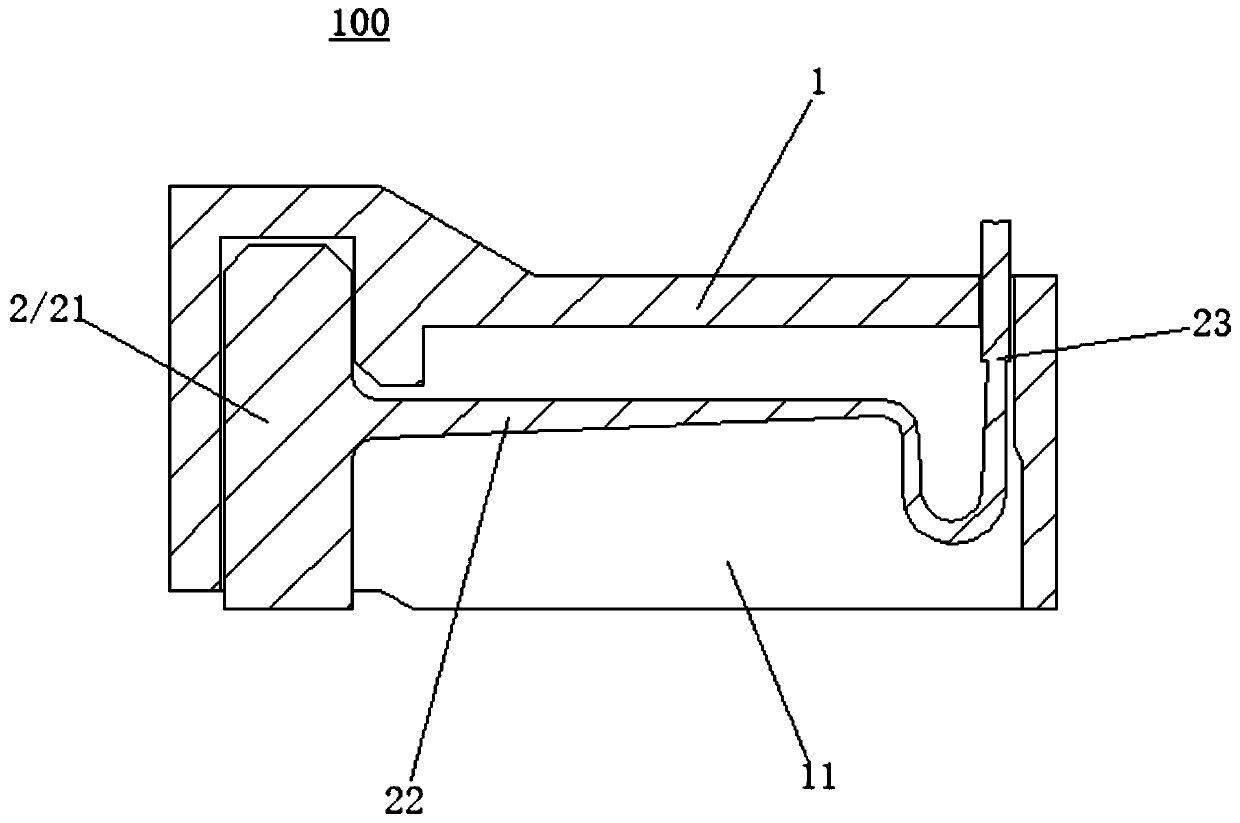

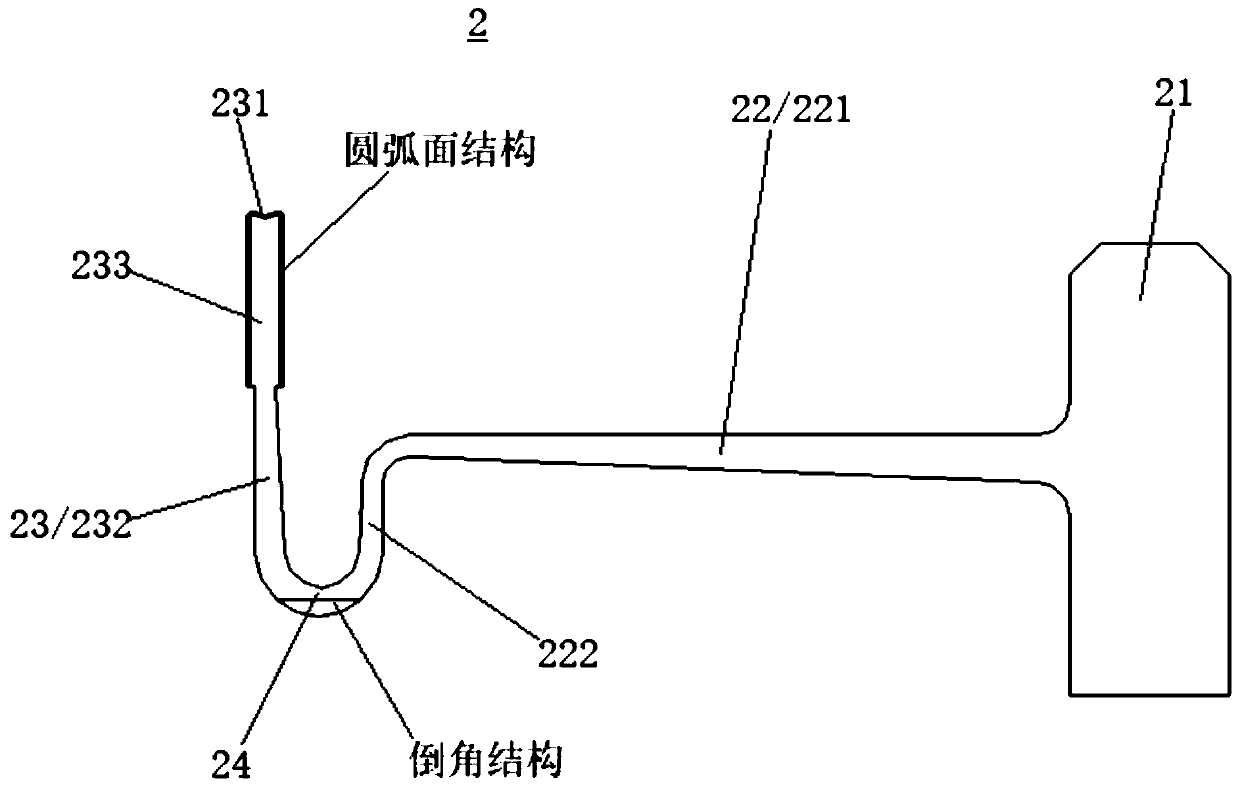

[0025] Please refer to Figure 1-Figure 4 , this embodiment is an inner arc type variable cross-section L-shaped terminal electric measuring fixture 100, which includes a plastic shell 1, a number of terminal strips 2 that are placed in the plastic shell 1 and partially exposed, and the terminal strips 2 include a bottom and a circuit. The supporting welding leg plate 21 for plate welding, the L-shaped connecting arm 22 extending forward from the front edge of the supporting welding leg plate 21, and the contact piece 23 formed by bending upward from the free end of the L-shaped connecting force arm 22 The L-shaped connection arm 22 includes a horizontal support section 221 and a first vertical connection section 222 bent downward from the free end of the horizontal support section 221 . The free end surface of the contact piece 23 is provided with a concave arc surface 231 . Through the structural design of the L-shaped connecting force arm 22 , the L-shaped structure is adop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com