Device for linear control of segmental prefabricated assembled curved bridge

A technology of linear control and prefabricated assembly, which is applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of lack of mature and perfect detection methods, and achieve the effects of easy control, simple method flow, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

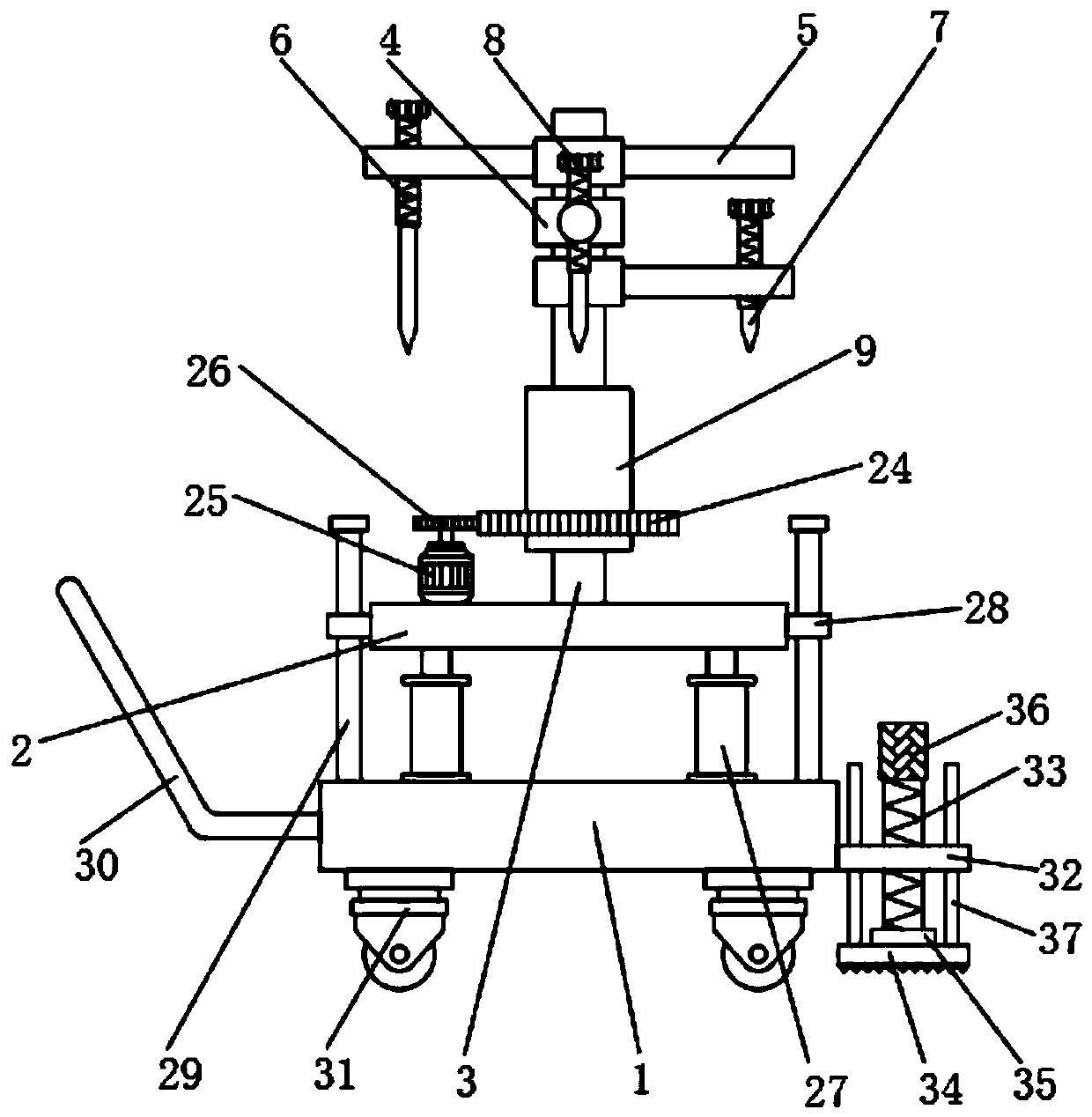

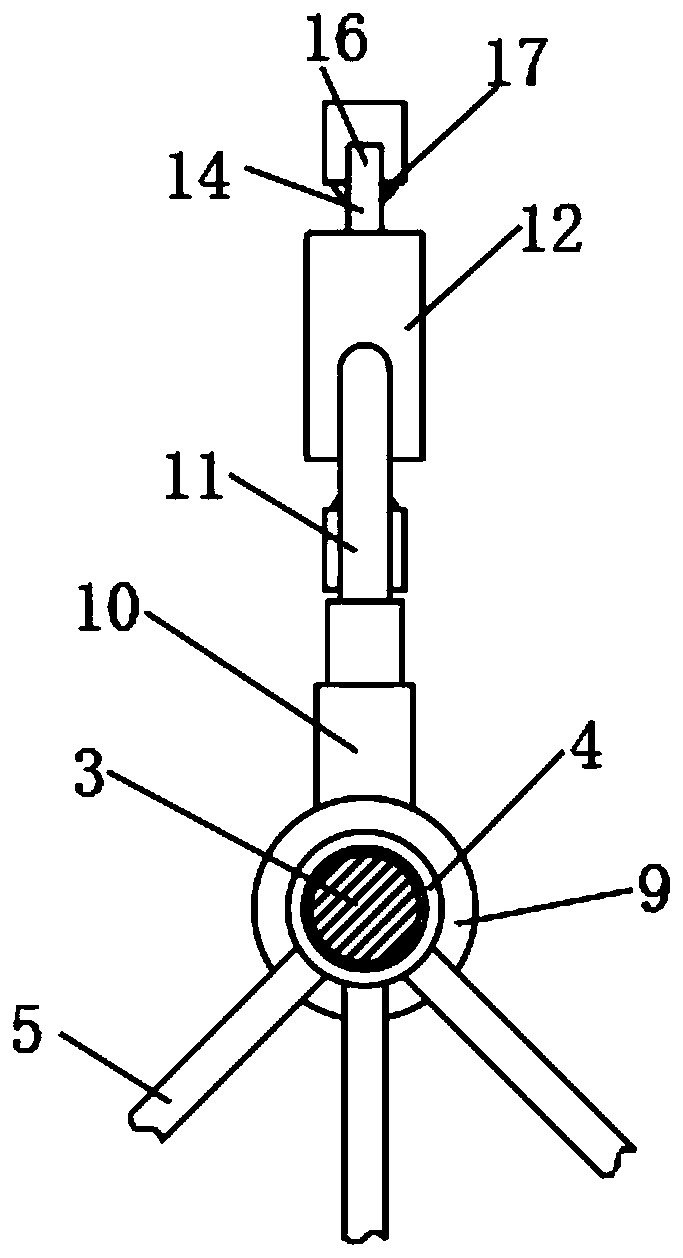

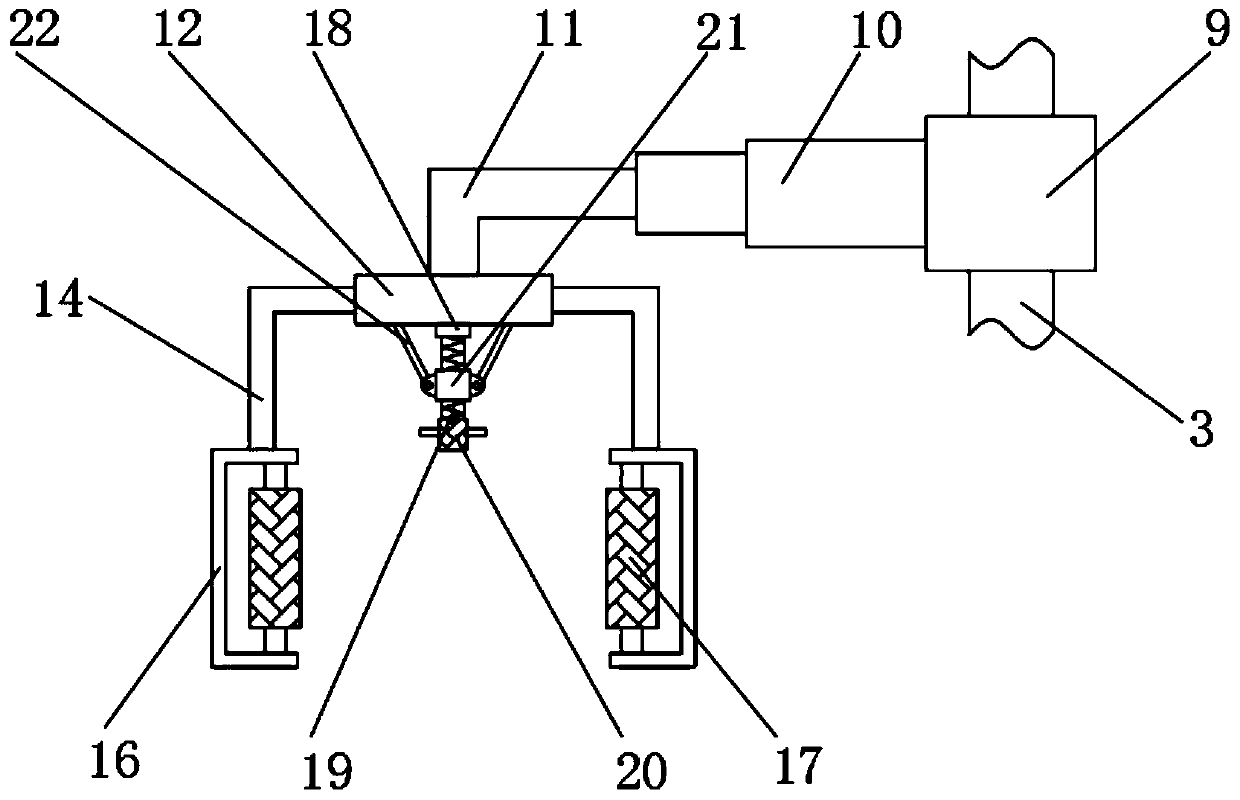

[0045] see Figure 1-2 , a device for controlling the alignment of segmental prefabricated curved bridges, including a alignment control detection device and a detection method, the alignment control detection device includes a device base 1, and an adjustment base 2 is movably installed above the device base 1, and the adjustment base 2 The main shaft 3 is fixedly installed on the top, and the outer wall of the main shaft 3 is rotatably connected with three connecting rings 4. The insides of the three connecting rings 4 are threaded with the first screw rod 6, and the bottom ends of the first screw rod 6 are fixedly connected with the positioning rod 7. , the bottom end of the positioning rod 7 is set to be conical, the distance between the three positioning rods 7 and the center line of the main shaft 3 is equal, and the distance between the positioning rod 7 and the center line of the main shaft 3 is d, the radius of the inside of the arc beam body for r 1 , the outer radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com