Active carbon fiber pretreatment reactor

An activated carbon fiber, pretreatment technology, applied in liquid/gas/vapor fiber/sliver/roving treatment, fiber chemical characteristics, textile material treatment, etc. The effect of improving the impregnation speed and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

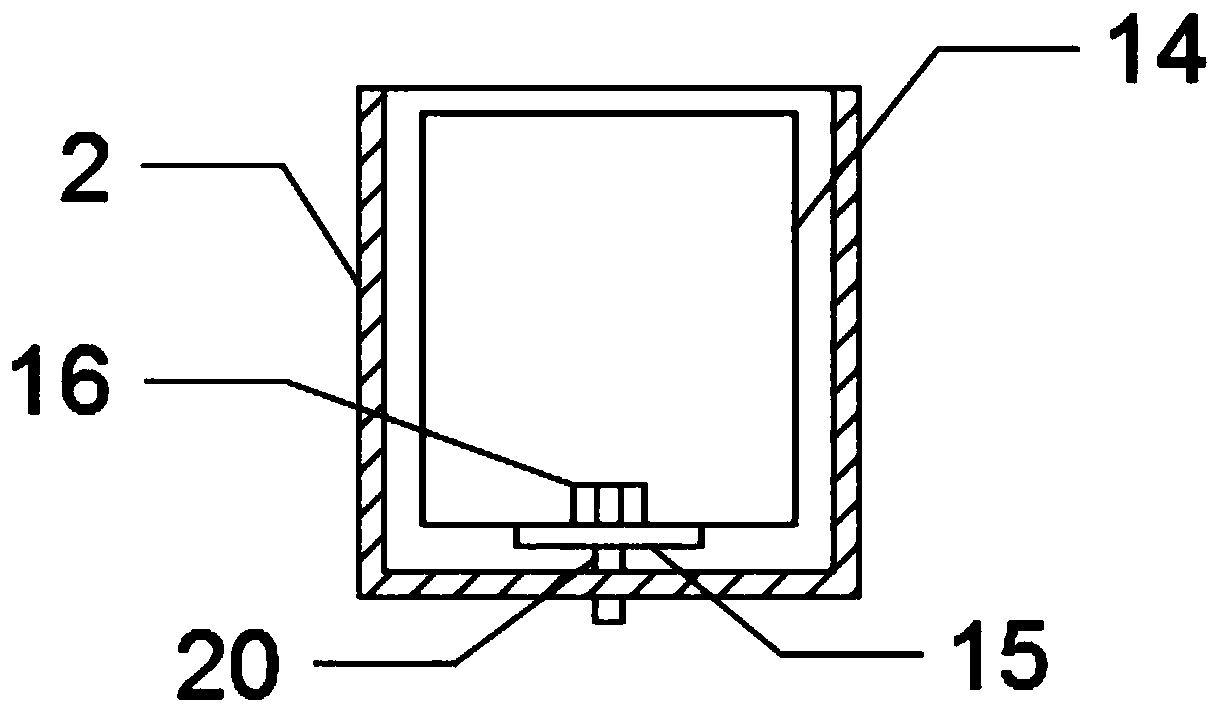

[0023] Such as Figure 1-Figure 6 As shown, the activated carbon fiber pretreatment reactor provided in this embodiment includes a base 1, a pretreatment reaction tank 2 is arranged above the base 1, and a pretreatment reaction turret 14 is arranged inside the pretreatment reaction tank 2. The inside of turn frame 14 is provided with a plurality of net cages 17, and the lower end of pretreatment reaction tank 2 is provided with acceleration motor 5, and the right side of acceleration motor 5 is provided with the circulation pipeline 7 that is connected with pretreatment reaction tank 2, and the circulation pipeline 7 One end is connected with a circulation pump 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com