Film pasting machine convenient and quick to operate

A technology of convenient operation and laminating machine, applied in the direction of coating, etc., can solve the problems of inconvenient cleaning, air bubble deflection machine, inconvenient maintenance, etc., and achieve the effect of easy to find problems and convenient regular maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

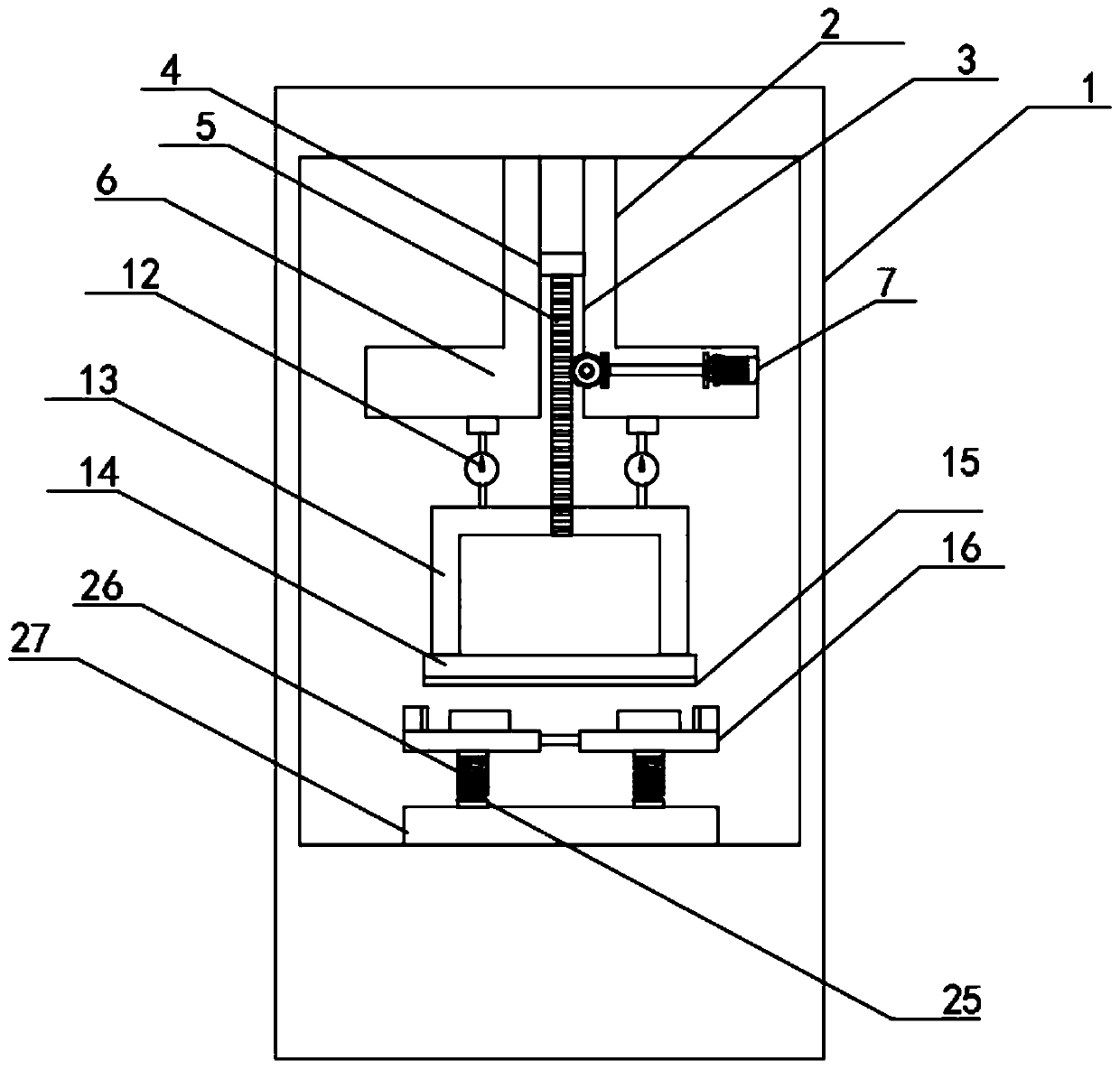

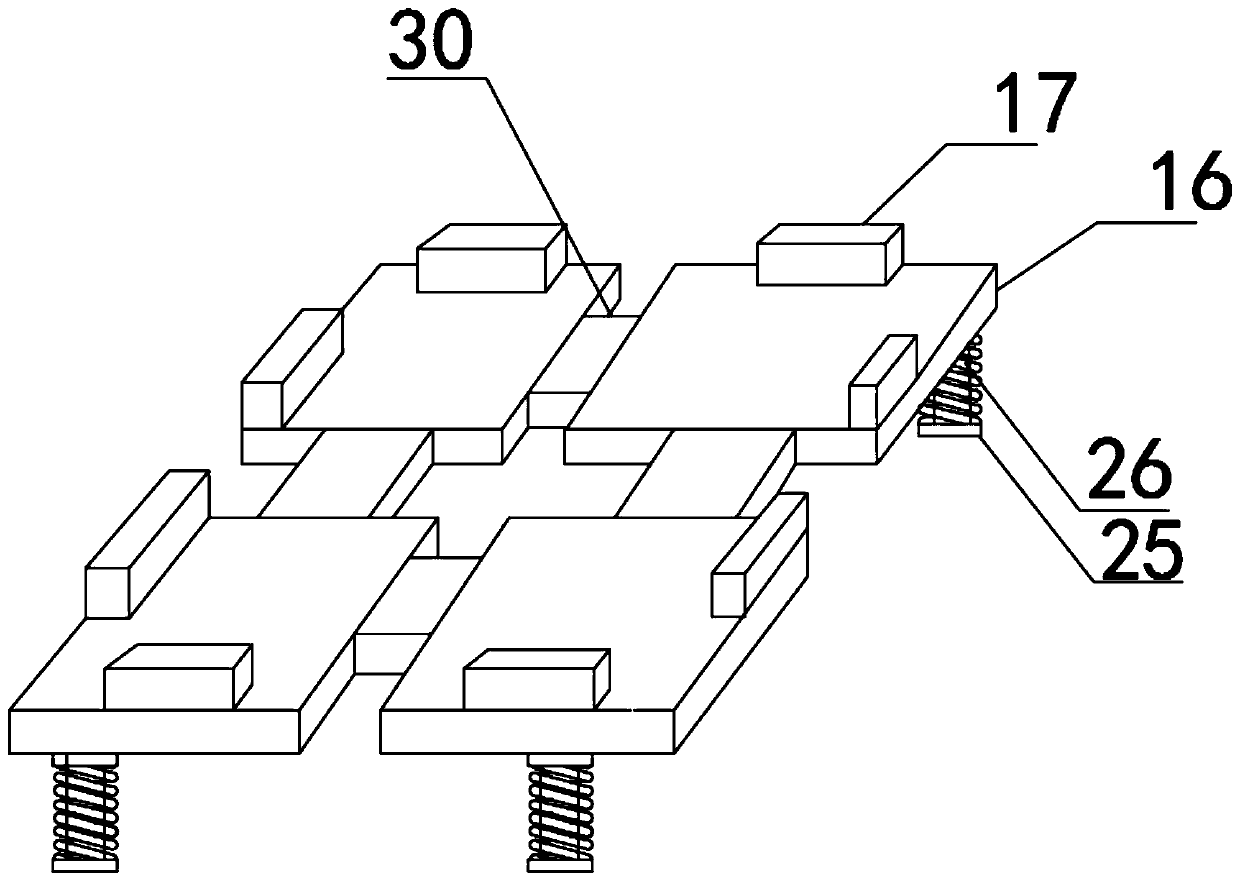

[0026] Refer to the attached Figure 1-5 , an easy-to-operate film lamination machine in this embodiment includes a convenient-to-operate film lamination machine, an easy-to-operate film lamination machine, including a film lamination machine body, a fixed column 2 is arranged on the top of the film lamination machine body 1, and the The inside of the fixed column 2 is provided with a telescopic hole 3, and the inside of the telescopic hole 3 is sleeved with a sliding dome 4, and the bottom of the sliding dome 4 is fixed with a threaded rod 5, and the bottom of the threaded rod 5 is fixed with a power device 6 , the inside of the power unit 6 is fixed with a servo motor 7, the top of the servo motor 7 is fixedly connected to the rotating shaft 8, the bottom of the rotating shaft 8 is fixedly connected to the helical gear set 9, and the bottom of the power unit 6 is fixedly provided with a tension gauge 12. The bottom of the tension gauge 12 is fixed with a pressure column 13, ...

Embodiment 2

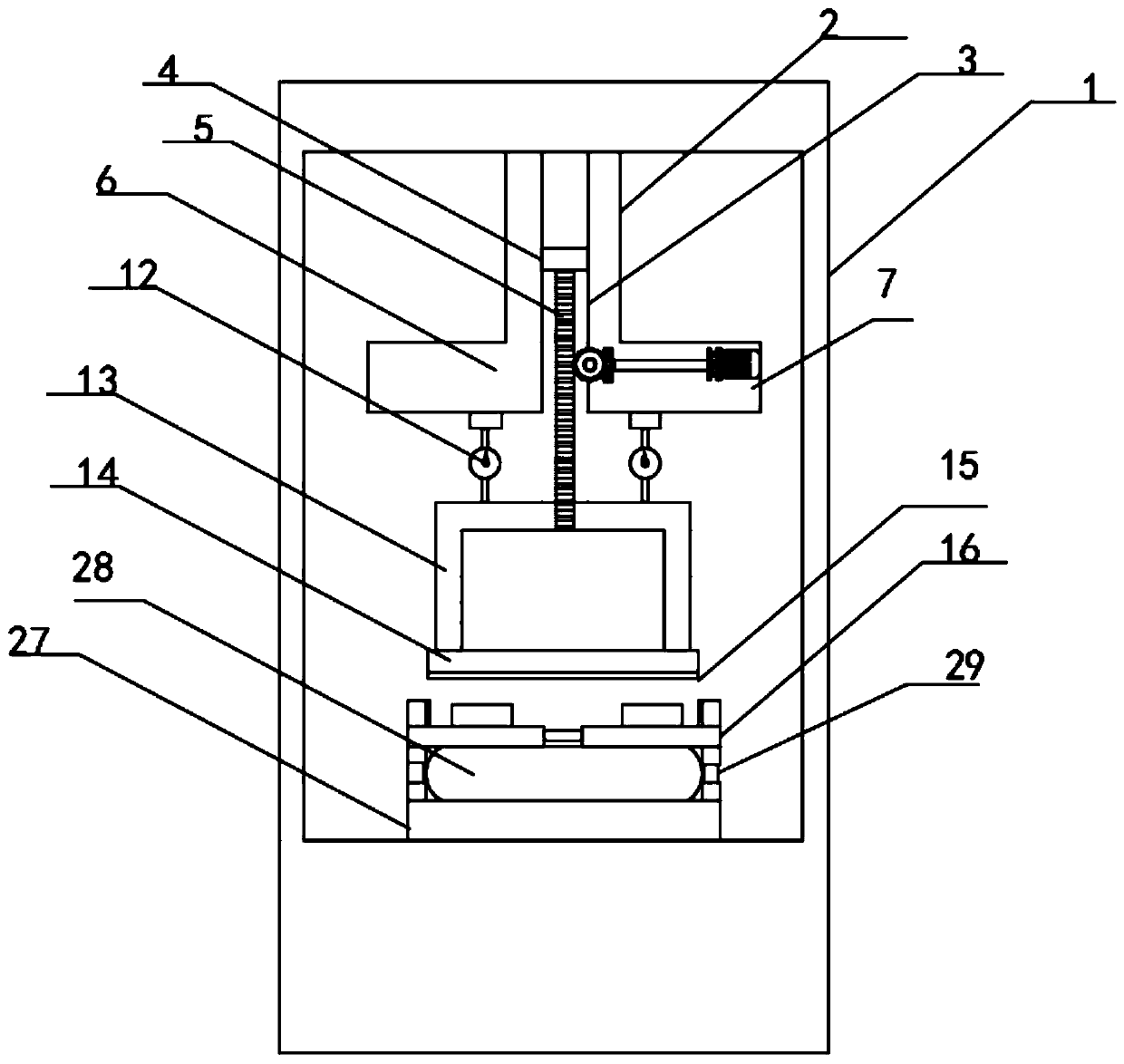

[0034] The difference from Embodiment 1 is that: the bottom of the fixed plate 16 is fixed with a circular airbag 28, and one side of the circular airbag 28 is fixed with a telescopic rod 29. When the servo motor is running, the circular airbag 28 can effectively buffer The pressure applied by the pressure plate 14 to press down the film has prevented excessive pressure from causing damage to the product.

[0035] The specific implementation scenario is: when the film sticking machine is running, the circular airbag 28 can effectively buffer the pressure exerted by the pressure plate to press the film downwards, preventing product damage caused by excessive pressure, and the four telescopic rods 29 can effectively control the circular airbag 28. When pressing, the strength spreads to the surroundings to stabilize the buffer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com