Cyclopentane foaming device

A foaming equipment, cyclopentane technology, applied in the field of polyurethane foaming, can solve the problems of large volume, many driving motors, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

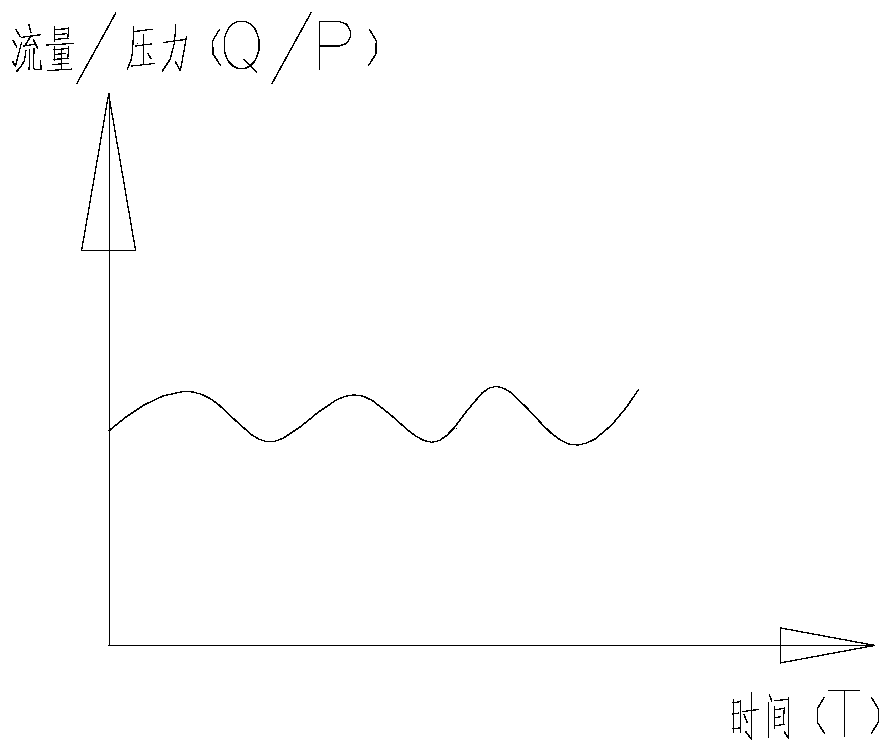

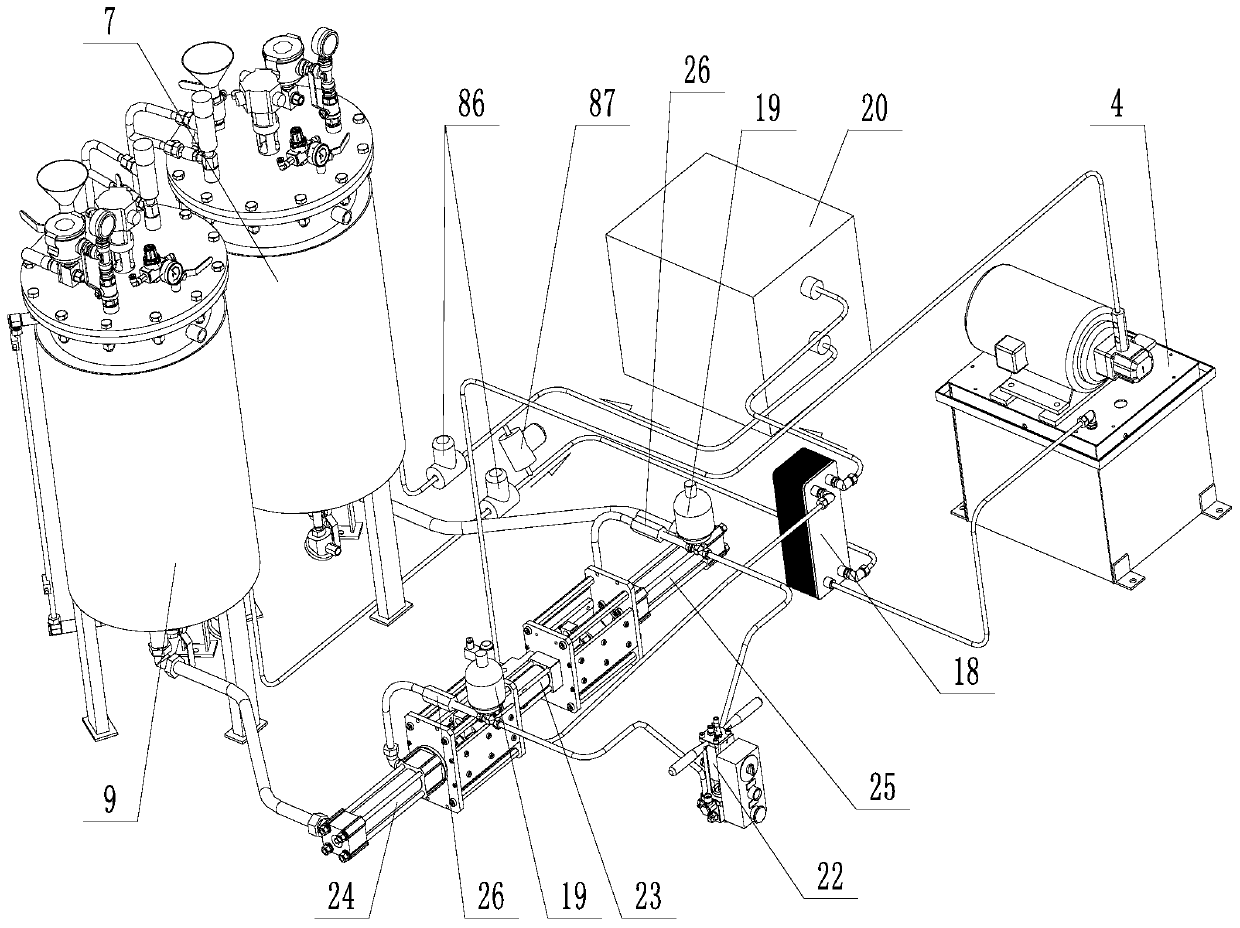

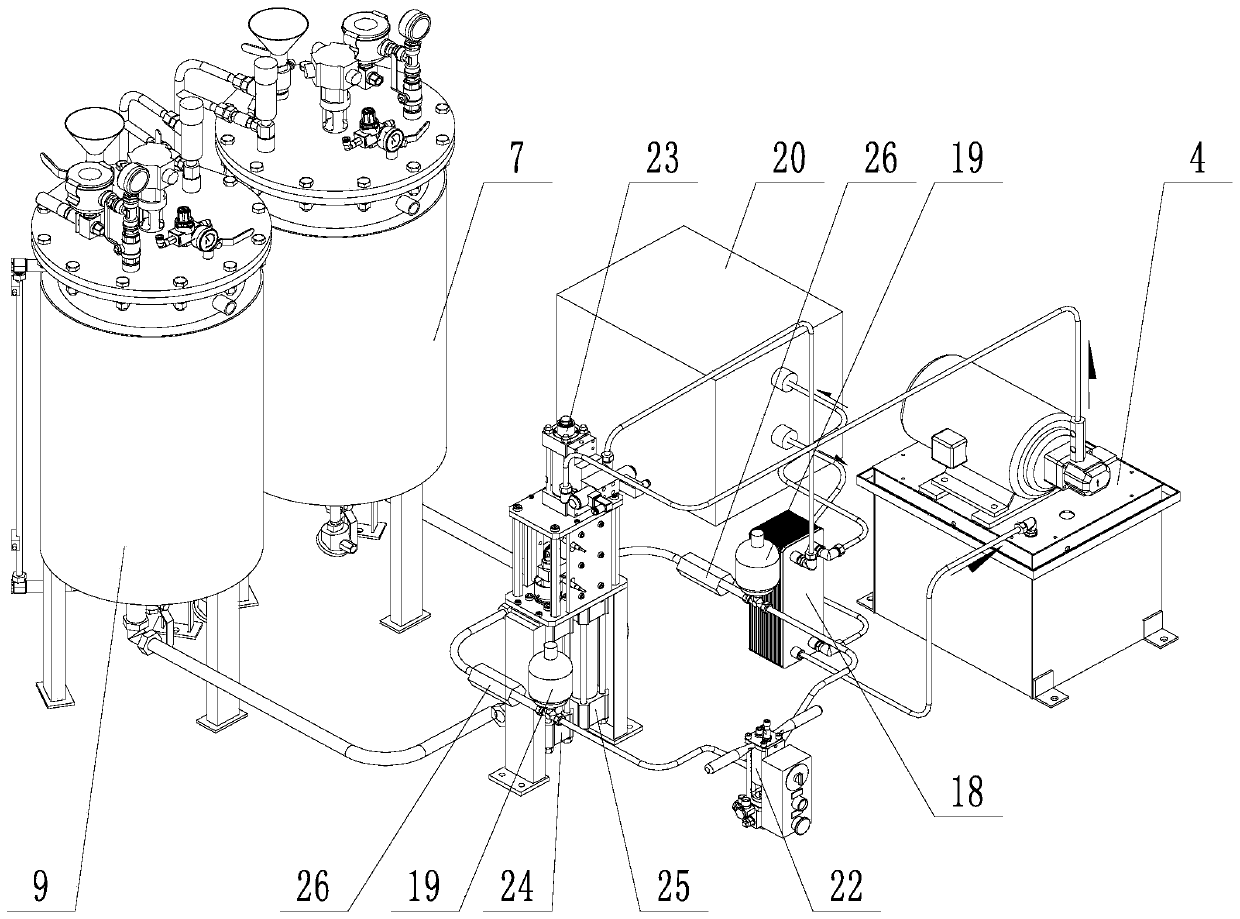

[0045] Such as figure 2 , image 3 and Figure 5 A kind of cyclopentane foaming equipment shown, comprises white material tank 9, black material tank 7, the mixing head 22 that is used for polyurethane foaming, also comprises high-pressure metering pump 5, and described high-pressure metering pump 5 is used for white The material and the black material are pumped to the mixing head 22 respectively; the pipelines of the high-pressure metering pump 5 pumping the white material and the black material are all connected to the accumulator 19, and the back pressure of the accumulator 19 on the pipeline of the pumping white material is greater than The accumulator 19 back pressure on the pipeline that pumps the black material. In the present embodiment, the accumulator 19 is an airbag type accumulator, wherein the inflation pressure of the accumulator 19 on the pipeline for pumping white material is 0.5 to 50% larger than the inflation pressure of the accumulator 19 on the pipelin...

Embodiment 2

[0051] On the basis of Example 1, such as figure 2 , image 3 and Figure 5 As shown, the high-pressure metering pump 5 includes a driving member 23, and the driving member 23 is used to drive the white material metering cylinder 24 and the black material metering cylinder 25 to act simultaneously. The white material is pumped, and the black material metering cylinder 25 pumps the black material from the black material tank 7 . Wherein the volume of the white material metering cylinder 24 is less than the volume of the black material metering cylinder 25 . In this embodiment, the volume ratio of the white material metering cylinder 24 to the black material metering cylinder 25 is 1:1.2. In this embodiment, the driving member 23 is a hydraulic cylinder, and also includes a hydraulic station 4 that matches the hydraulic cylinder. The pipeline that returns the hydraulic cylinder to the hydraulic station 4 is connected to a cooling device 18, and the cooling device 18 uses a w...

Embodiment 3

[0057] On the basis of any of the above-mentioned embodiments, such as Figure 5 As shown, the white material tank 9, the black material tank 7, and the high-pressure metering pump 5 are all located in the airtight enclosure, and the detection probe 17 for detecting the concentration of cyclopentane is arranged in the airtight enclosure, and also includes a For the fan that discharges the gas in the airtight enclosure, the fan is controlled by the detection signal of the detection probe 17; the airtight enclosure and all equipment in the airtight enclosure are grounded, and the grounding resistance is guaranteed to be less than 4Ω. The air discharge end of blower fan passes through blower blower air outlet 15 to the outside of airtight enclosing room, is convenient to gas discharge.

[0058] Among them, the pressure sensor 3 is used to monitor the pressure before the white material and black material enter the mixing head. When the pressure difference between the two is too la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com