Welding fixing frame for interface frame cable connector

A technology of cable connectors and fixing frames, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of increasing welding operation difficulty, reducing production efficiency, and affecting welding quality, and achieves simple structure and improved Improve production efficiency and reduce the effect of false welding and false welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

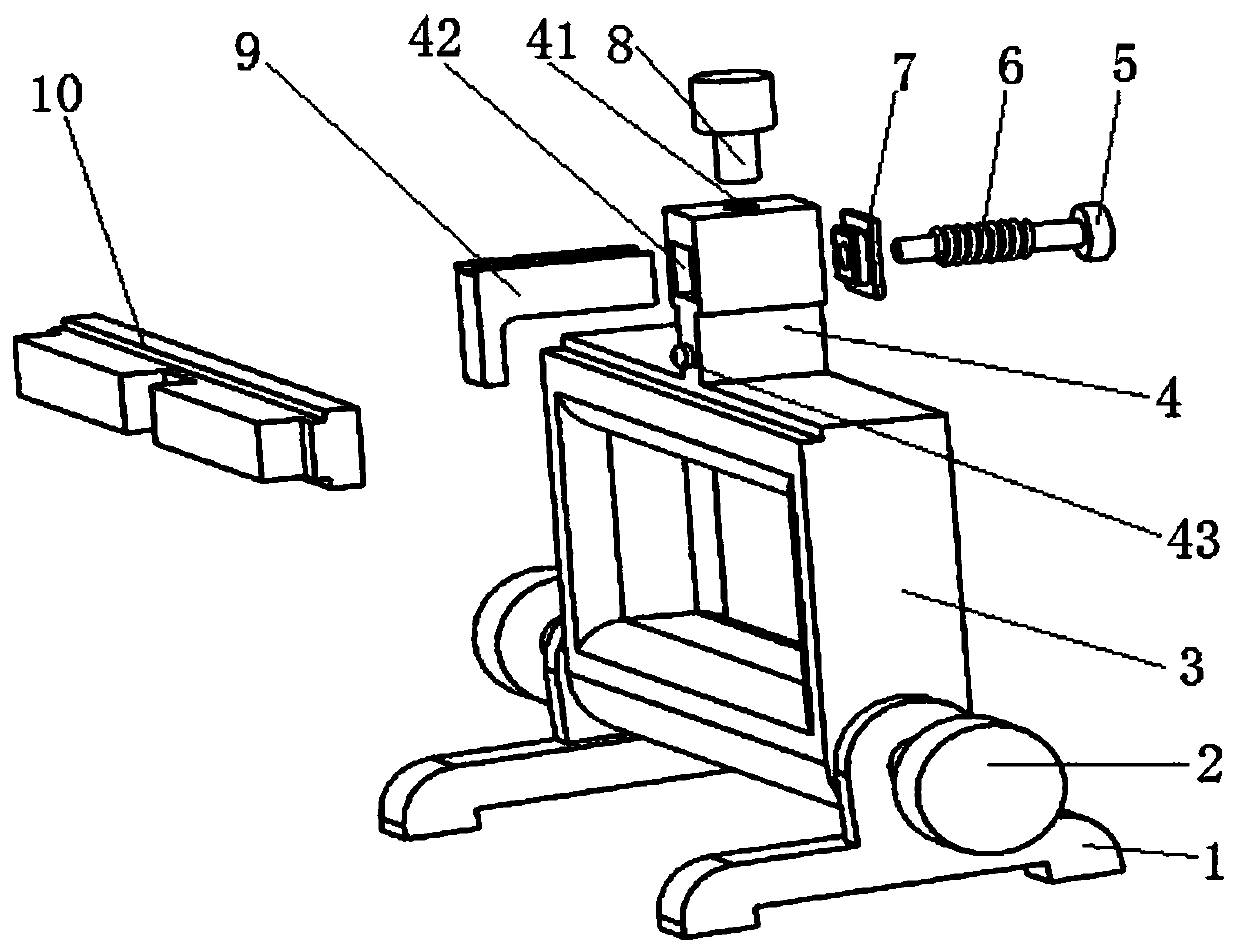

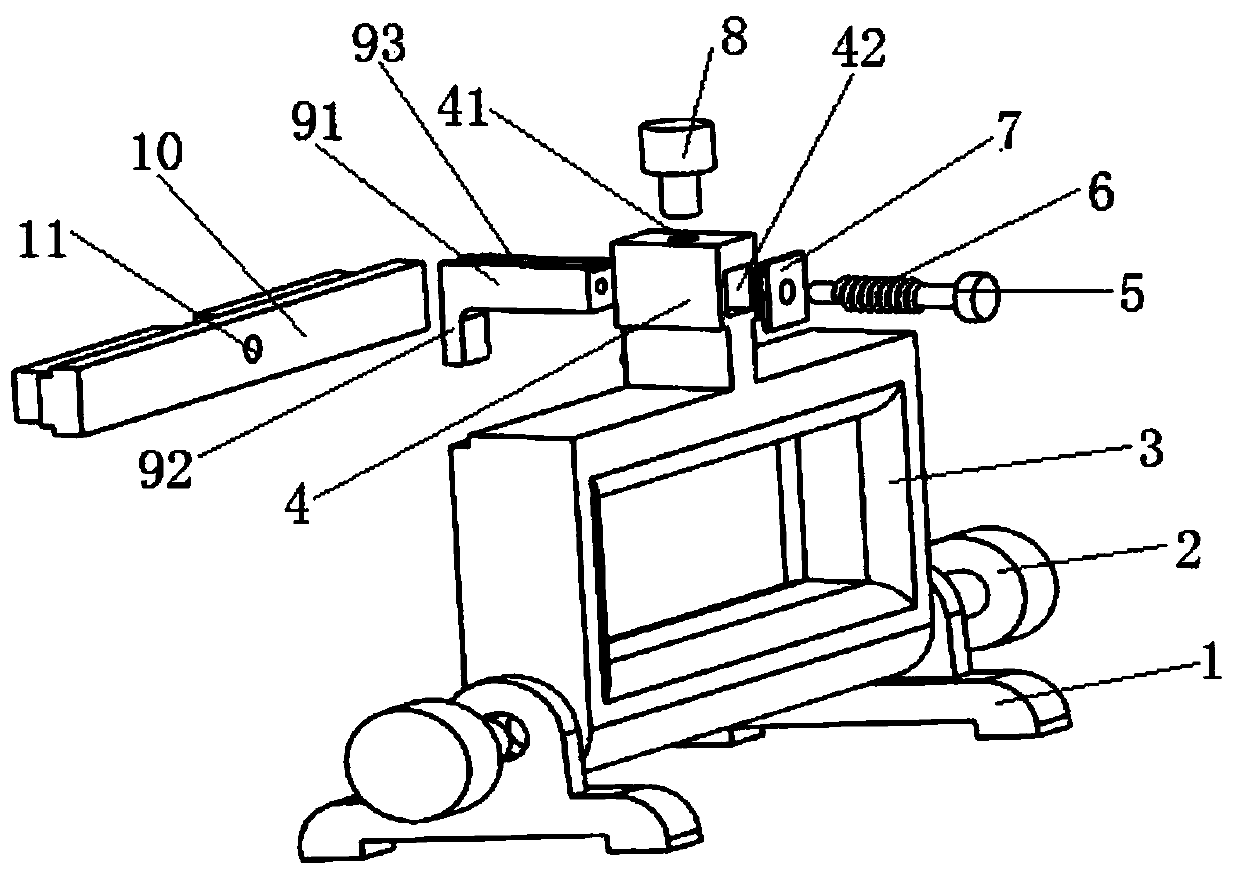

[0012] Such as figure 1 and 2 As shown, a welding fixing frame for an interface frame cable connector of the present invention includes: two legs 1, two locking nails 2, a welding frame 3, a clamp body 4, a connecting rod 5, a spring 6, and a baffle plate 7 , sliding clamp 9 and locking bolt 8.

[0013] The welding frame 3 is a rectangular frame, and two legs 1 are respectively fixed at both ends of the bottom of the welding frame 3 by two locking nails 2 . The fixture main body 4 is fixed on the top center of the welding frame 3 , the side of the fixture main body 4 is provided with a sliding channel 42 , and the top is provided with a locking screw hole 41 communicating with the sliding channel 42 . The sliding clip 9 includes a sliding part 91 and a clamping part 92 perpendicular to each other. The baffle plate 7 is covered at the entrance of one side of the sliding channel 42 . One side entrance protrudes. The connecting rod 5 passes through the through holes of the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com