Full-nutrition formula emulsion, and preparation method and application thereof

A technology of complete nutrition and formulation, which is applied in the direction of application, food ingredients as emulsifiers, and fat-containing food ingredients, etc., can solve the problems of not being able to adapt to disease-specific metabolic changes, reduce overall costs, take into account the taste, and improve metabolic disorders. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] In addition, the embodiment of the present invention also provides a method for preparing the above-mentioned specific full-nutrition formula emulsion suitable for obesity and fat reduction surgery population, which may include the following steps, for example:

[0041] 1) Mix the base material evenly and add it to hot water at 40°C-60°C, stir at a high speed to dissolve it completely and form a water phase;

[0042] 2) Add emulsifiers into hot oil at 45°C-65°C and dissolve with magnetic stirring to form an oil phase;

[0043] 3) Use a high-speed shearing machine to perform high-speed shearing on the water phase obtained in step 1) at 10,000 to 20,000 rpm, and slowly add the oil phase obtained in step 2). After the oil phase is completely added, keep shearing for 10 to 20 minutes to obtain a milky liquid;

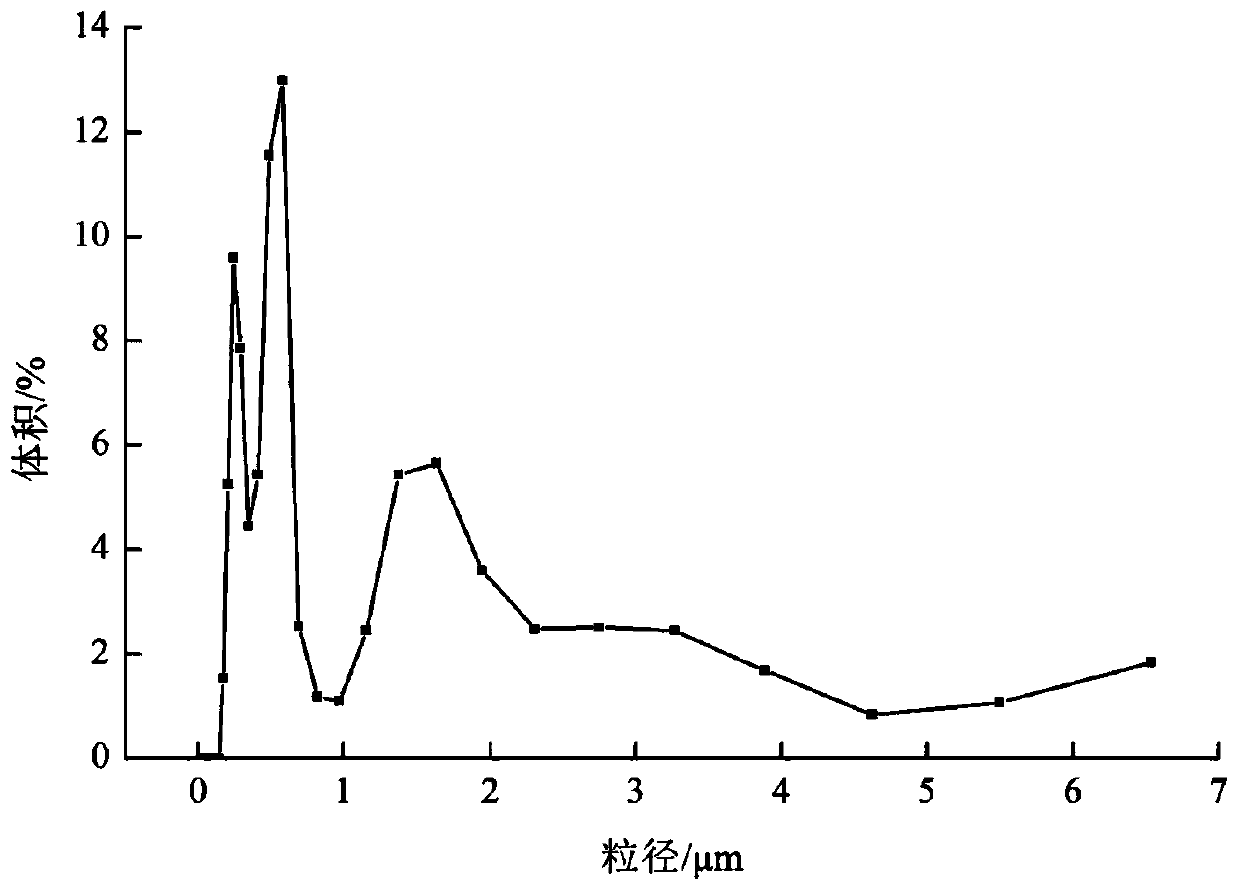

[0044] 4) Use a high-pressure homogenizer to homogenize the emulsion obtained in step 3) at 30-60°C for 3 times, and the homogenization pressure is 30-50Mpa;

[00...

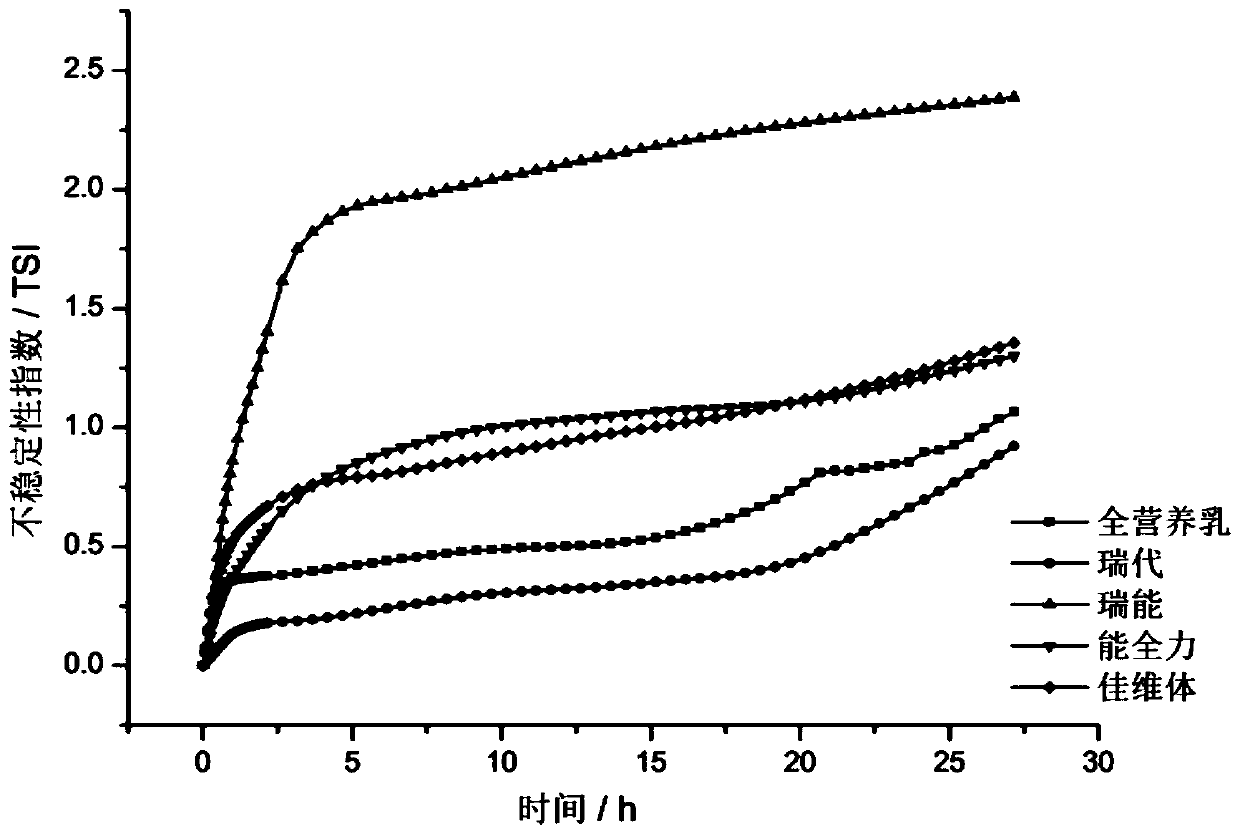

Embodiment 1

[0048] Prepare raw materials according to the following mass percentages: 4% soy protein isolate; 6% whey protein concentrate; 4% maltodextrin; 1% resistant dextrin; 6% sucrose; 0.5% inulin; 0.07% Sodium carbonate; 0.5% complex minerals; 0.02% multivitamins; 0.02% xanthan gum; 0.03% locust bean gum; 1.63% refined soybean oil; 0.41% refined rapeseed oil; 0.2% purple Su seed oil; 0.56% medium chain triglycerides (MCT); 0.04% phospholipids; 0.03% sodium stearoyl lactylate; 0.03% monoglycerides; 0.03% tea polyphenol palmitate; 80% drinking water.

[0049] 1) Mix the base material evenly and add it to warm water at 50°C, stir at a high speed to dissolve it completely to form a water phase;

[0050] 2) Add emulsifiers to hot oil at 60°C and dissolve with magnetic stirring to form an oil phase;

[0051] 3) Use a high-speed shearing machine to perform high-speed shearing on the water phase obtained in step 1) at 10000 rpm, and slowly add the oil phase obtained in step 2), and keep s...

Embodiment 2

[0055] Prepare raw materials according to the following mass percentages: 5% soy protein isolate; 5% whey protein concentrate; 5% maltodextrin; 5% sucrose; 0.5% resistant dextrin; 1% inulin; 0.07% Sodium carbonate; 0.7% complex minerals; 0.02% multivitamins; 0.02% xanthan gum; 0.03% locust bean gum; 1.63% refined soybean oil; 0.41% refined rapeseed oil; 0.2% purple Su seed oil; 0.56% medium chain triglycerides (MCT); 0.04% phospholipids; 0.03% sodium stearoyl lactylate; 0.03% monoglycerides; 0.03% tea polyphenol palmitate; 80% drinking water.

[0056] 1) Mix the base material evenly and add it to warm water at 50°C, stir at a high speed to dissolve it completely to form a water phase;

[0057] 2) Add emulsifiers to hot oil at 60°C and dissolve with magnetic stirring to form an oil phase;

[0058] 3) Use a high-speed shearing machine to perform high-speed shearing on the water phase obtained in step 1) at 10000 rpm, and slowly add the oil phase obtained in step 2), and keep s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com