Manganese spinel doped with magnesium, cathode material comprising same, method for preparing same and lithium ion battery comprising same

A lithium-ion battery, manganese spinel technology, applied in the field of energy storage systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Example 1: Preparation of manganese spinel doped with magnesium

[0057] Pure spinel (LiMnO 4 ) and spinel doped with Mg (LiMg 0.05 mn 1.95 o 4 ). For the synthesis of manganese spinel, except for the addition of Mg(OH) to Mg-doped spinel 2 (≥99%, Fluka Analytical), use lithium raw material and manganese raw material respectively: Li 2 CO 3 (battery grade ≥99.5%, Rockwood–Chile) and Mn(CH 3 COO) 2 (≥99%, Sigma Aldrich).

[0058] For the synthesis, two aqueous solutions were prepared. The first solution corresponds to adding a stoichiometric amount of the metal ion precursor Li for pure spinel at room temperature 2 CO 3 and Mn(CH 3 COO) 2 and precursors of metal ions for Mg-doped spinel Li 2 CO 3 , Mn(CH 3 COO) 2 and Mg(OH) 2 Dissolved in distilled water, the second solution corresponds to dissolving the organic precursors ethylene glycol and citric acid in distilled water. The two aqueous solutions were mixed with constant stirring. The pH of the resul...

Embodiment 2

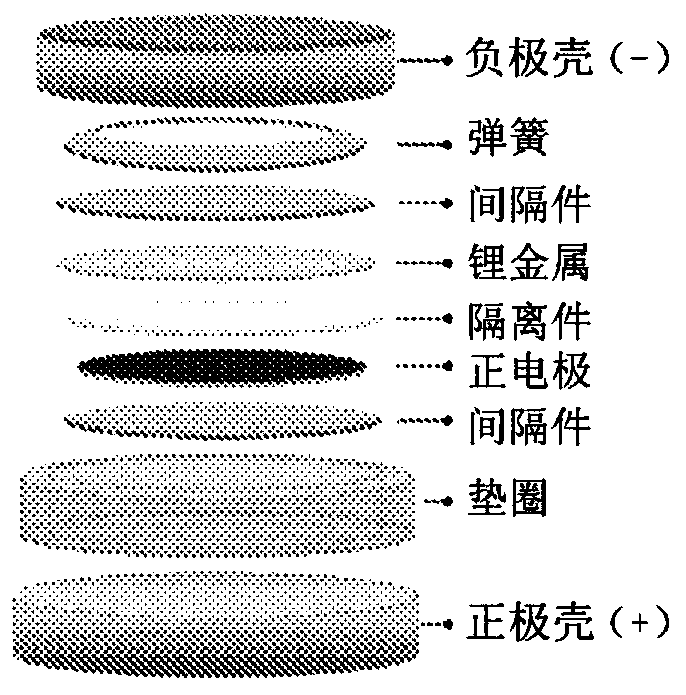

[0059] The preparation of embodiment 2 cathode coating

[0060] To make the cathode coating, a suspension in NMP solution (n-methylpyrrolidone) was prepared consisting of 90% by weight of cathode active material [pure manganese spinel (LiMn 2 o 4 ) or spinel doped with Mg (LiMg 0.05 mn 1.95 o 4 ) or commercial spinel (Li 1.16 mn 1.84 o 3.996 S 0.004 )], 5% by weight of carbon black as a conductive additive, and 5% by weight of PVdF (polyvinylidene fluoride) as a binder. The mixing process of the coating suspension was carried out in a paddle mixer under static vacuum conditions (=0.1 atmospheres) to minimize water contamination of the suspension. The different components of the positive electrode, cathode active material, conductive additive and binder were added one by one to minimize agglomeration and achieve homogeneity of the suspension.

[0061] The obtained suspension was deposited on Al paper as a current collector for cathodic coating, and then underwent a pre...

Embodiment 3

[0068] Example 3: Characterization of physical and chemical properties

[0069] The physical and chemical properties of the synthesized cathode materials and commercially available materials were determined by applying the following characterization techniques:

[0070] - Solid Picnometry to determine the apparent density of synthetic cathodically active compounds and commercially available products.

[0071] - Scanning electron microscopy (SEM-EDS, TESCAN, Vega 3LMU) with X-ray dispersive spectroscopy detector to study the morphology, homogeneity of pure spinel, Mg-doped spinel and commercial spinel , particle size at the microchrome level, and elemental composition.

[0072] - Atomic Force Microscopy - Raman (AFM RAMAN, WITec, alpha300) to determine the particle size of the synthesized nanoscale cathode material.

[0073] - X-ray diffraction (DRX, Bruker, D8 Advance-A25) of crystalline powders using Cu Kα radiation to determine and compare structural parameters and identif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com