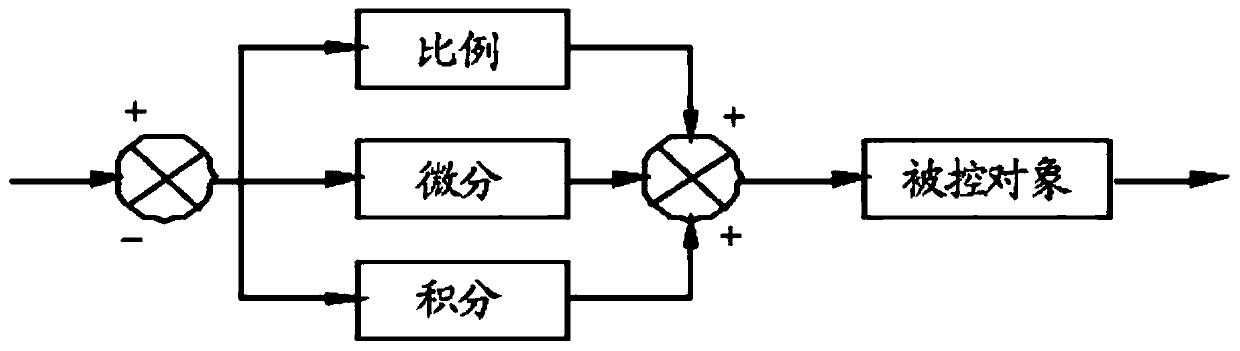

PID-based temperature grading control method

A hierarchical control and temperature control system technology, which is applied in the direction of temperature control using electric methods, auxiliary controllers with auxiliary heating devices, etc., can solve problems such as incoordination of temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

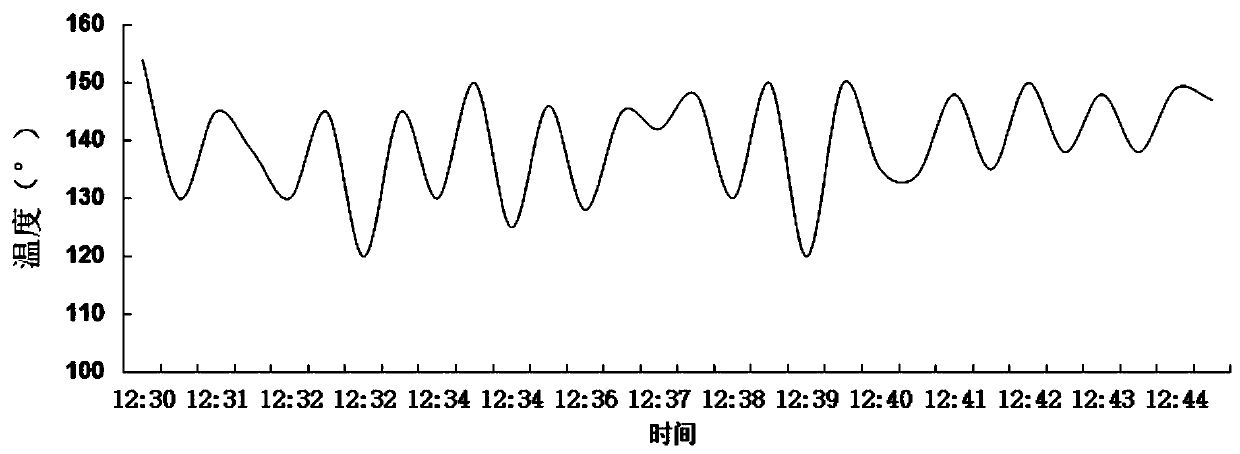

Examples

no. 1 example

[0041] Image 6 A general flow chart of the PID-based temperature hierarchical control method according to a preferred embodiment of the present invention is schematically shown.

[0042] Such as Image 6 As shown, in general, for example, the PID-based temperature hierarchical control method according to a preferred embodiment of the present invention may include:

[0043] The first step S1: detecting the percentage content of the moisture content of the shredded stems at the material outlet of the shred drying machine;

[0044] Second step S2: judging whether the percentage of moisture in the cut stems is greater than a threshold percentage; for example, the threshold percentage is 8%.

[0045] The third step S3: in the case that the percentage content of the cut stem moisture is greater than the threshold percentage value, set the proportional parameter, the integral parameter and the differential parameter of the PID controller to the first parameter combination, and then ...

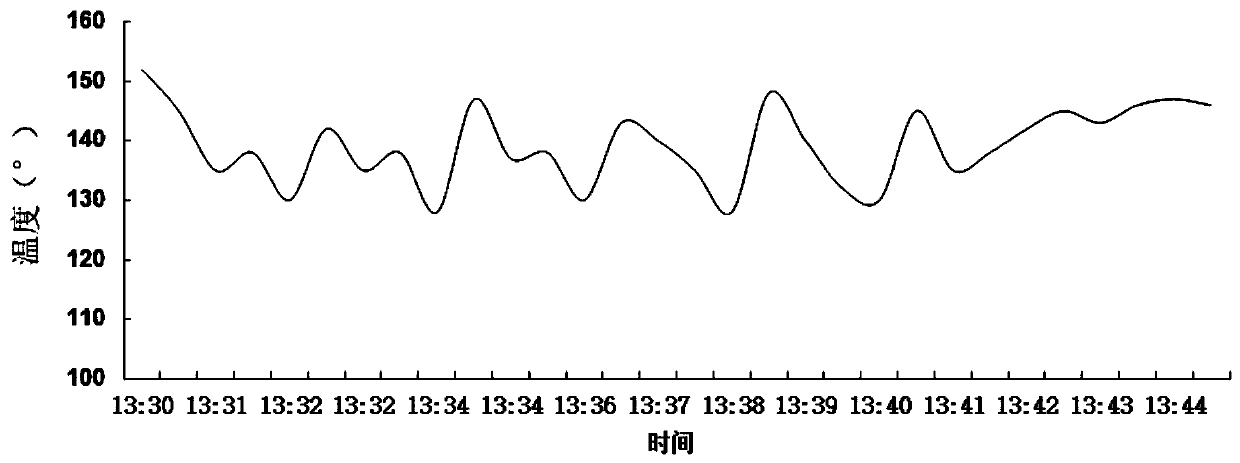

no. 2 example

[0052] In another scheme, detect the percentage content of the cut stem moisture at the material outlet of the silk drying machine; Reduce the numerical value of the proportional parameter, reduce the numerical value of the integral parameter, and increase the numerical value of the differential parameter, and then make the temperature control system execute the instruction issued by the PID controller under the new parameter to regulate the steam hot air temperature; When the content changes from not greater than the threshold percentage value to greater than or equal to the threshold percentage value, increase the value of the proportional parameter of the PID controller, increase the value of the integral parameter, and decrease the value of the differential parameter, and then make the temperature control system Execute the instructions issued by the PID controller under the new parameters to regulate the steam hot air temperature.

[0053] Also, for example, the threshold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com