A Quickly Replaceable Combined Magnetostrictive Guided Wave Phased Array Transducer

A magnetostrictive and phased array technology, applied to instruments, scientific instruments, and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve problems such as inconvenient installation and use, invalid excitation areas, etc., to improve applicability, practicality, and flexibility The effect of adjusting and increasing the flexibility of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

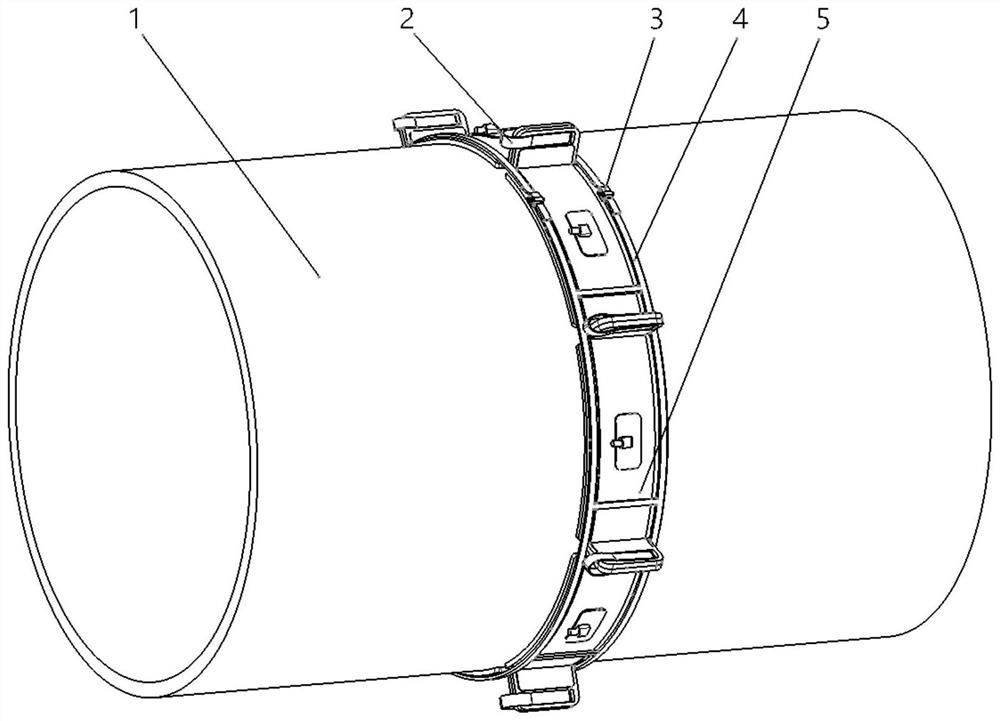

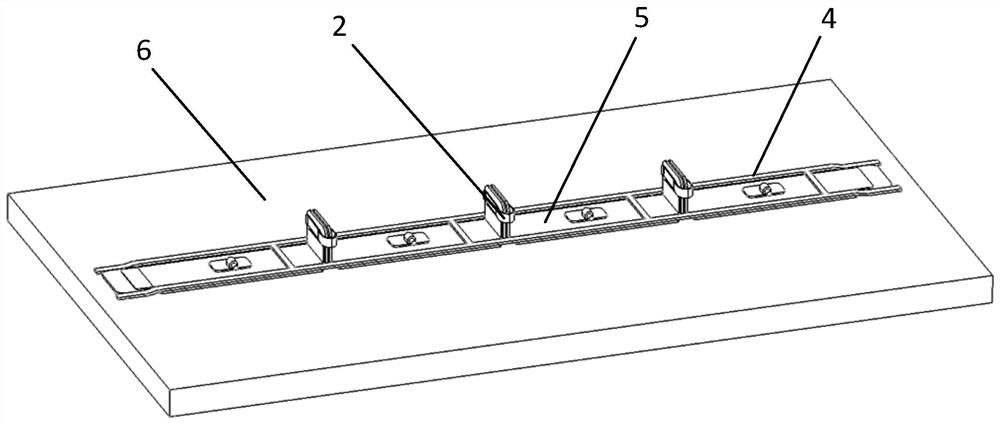

[0072] figure 2 As shown, when the phased array transducer of the present invention detects the metal plate 6, first fold up the two sides of the adjacent acoustic wave induction unit 5, and then fix them to the pre-tightened fixing belt 4 in turn, and use the probe clip 2 to align the two sides. The folded and pasted area adjacent to the acoustic wave induction unit 5 is fixed, and finally the combined phased array transducer is laid on the surface of the metal plate as a whole. Since there is no need to carry out circumferential pretension in the flat plate detection, the quick pretension device 3 at one end of the pretension fixing belt 4 can be removed. By increasing or decreasing the number of acoustic wave sensing units 5 and properly adjusting the size of the folded areas on both sides, the detection of metal plates with different widths can be adapted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com