Automatic steel wire shearing force checking device

An automatic calibration and shear force technology, applied in measuring devices, using repetitive force/pulsating force to test the strength of materials, instruments, etc., can solve the problem of no unified regulation of calibration devices, etc., to avoid manual pulling of moving wires, The effect of avoiding clamping force and facilitating wire shear test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

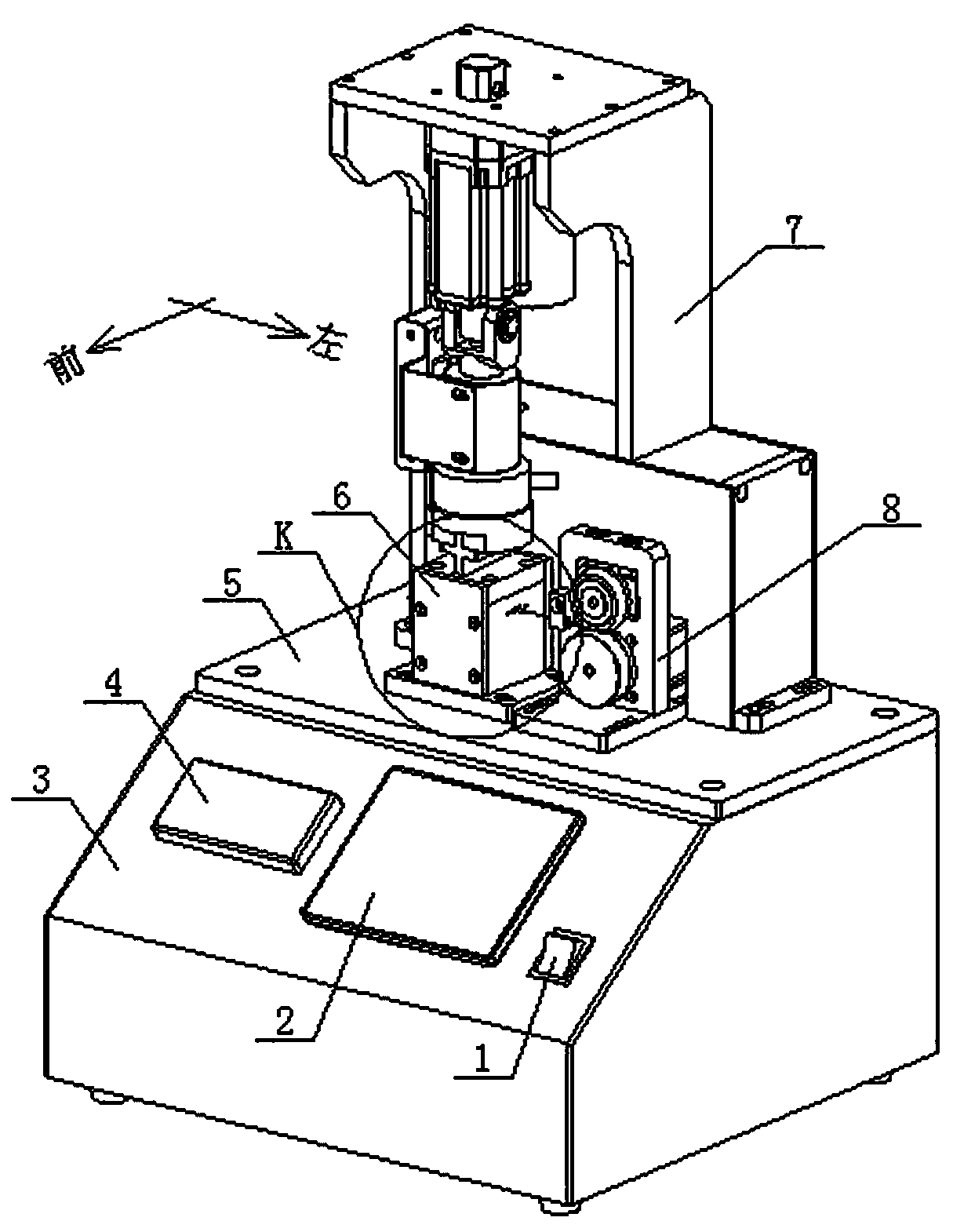

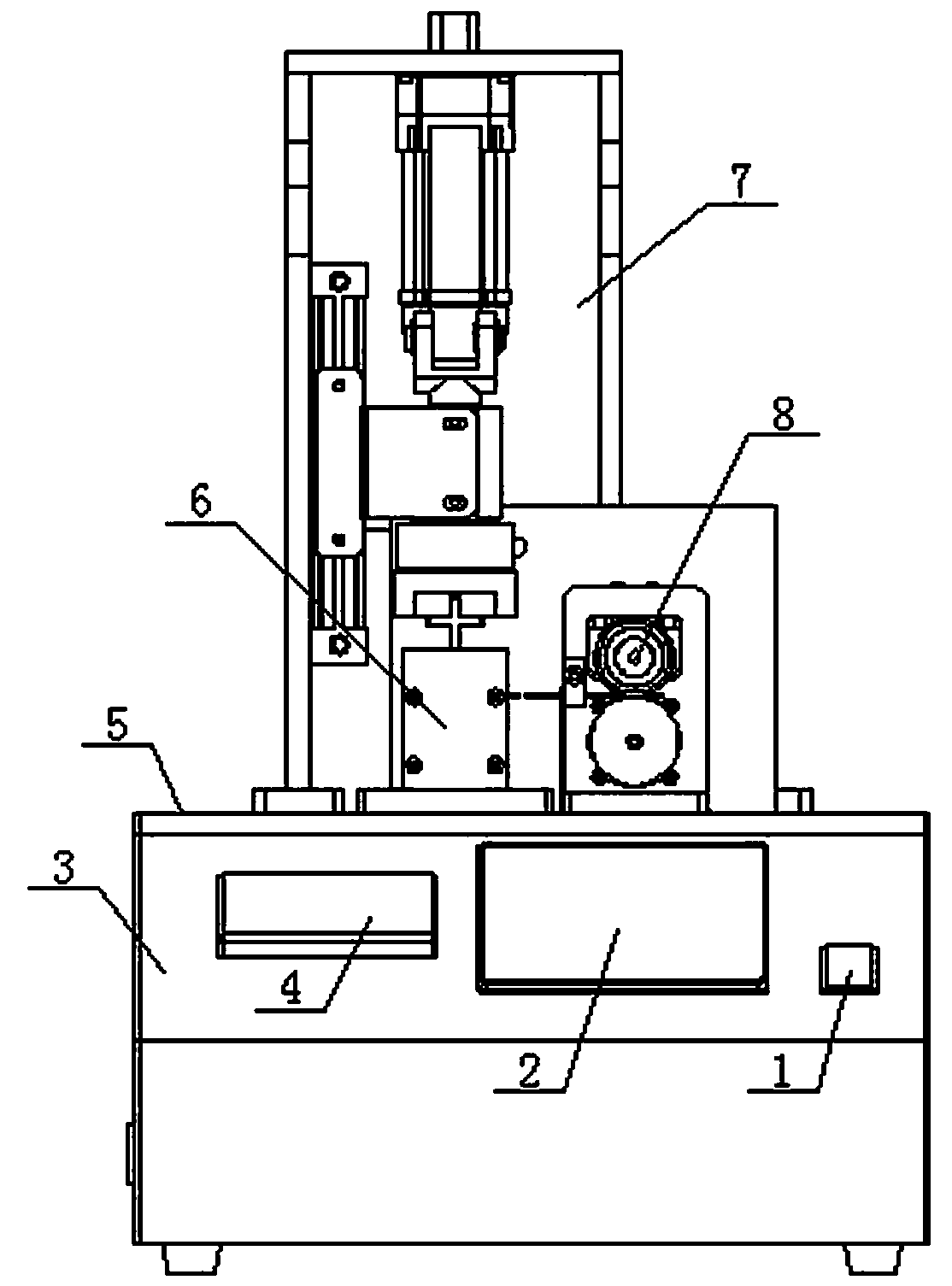

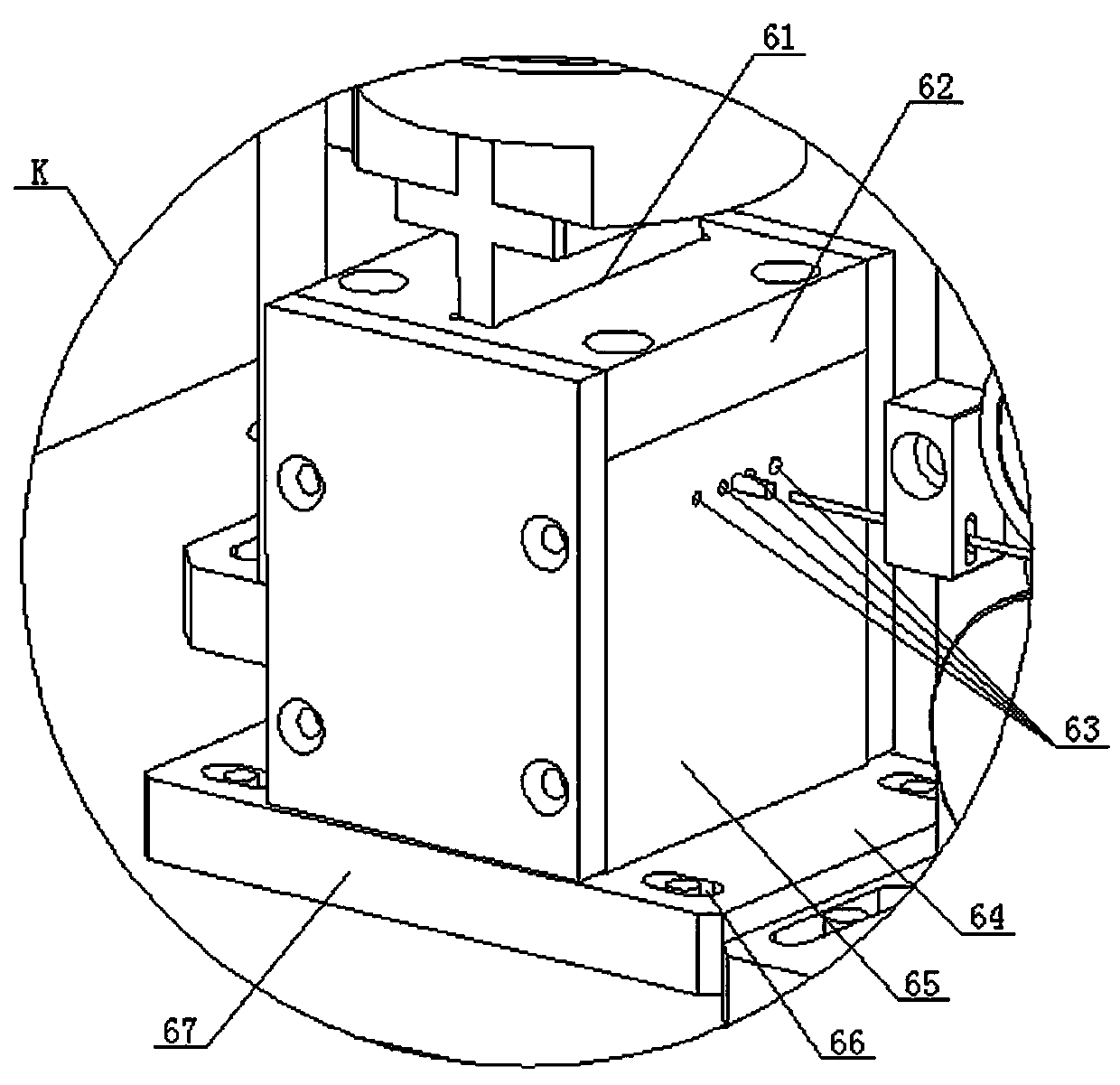

[0035] Such as Figure 1 to Figure 6 As shown, a steel wire shear force automatic calibration device includes a cabinet 3, the top of the cabinet 3 is a working platform 5, and a steel wire shearing mechanism 7, a steel wire supporting mechanism 6 and a steel wire conveying mechanism 8 are installed on the working platform 5, wherein The wire shearing mechanism 7 comprises a support frame body 74 fixed on the work platform 5, a hydraulic cylinder 75 with a piston rod 76 vertically downwardly arranged on the support frame body 74, and a pressure sensor 77 connected to the end of the piston rod 76 Moving blade 71; steel wire supporting mechanism 6 is positioned at moving blade 71 below, and the fixed blade that cooperates with moving blade 71 is installed on steel wire supporting mechanism 6, and steel wire conveying mechanism 8 is positioned at steel wire 9 input side p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com