A steel bar bending strength testing device equipped with an automatic guiding mechanism

A kind of steel bending and automatic guiding technology, which is applied in the direction of applying stable bending force to test material strength, measuring device, strength characteristics, etc., which can solve the problem that the detection frame cannot be adjusted quickly and accurately, and the relative bending of steel bars cannot be detected synchronously. Problems such as angle, single function of detection device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

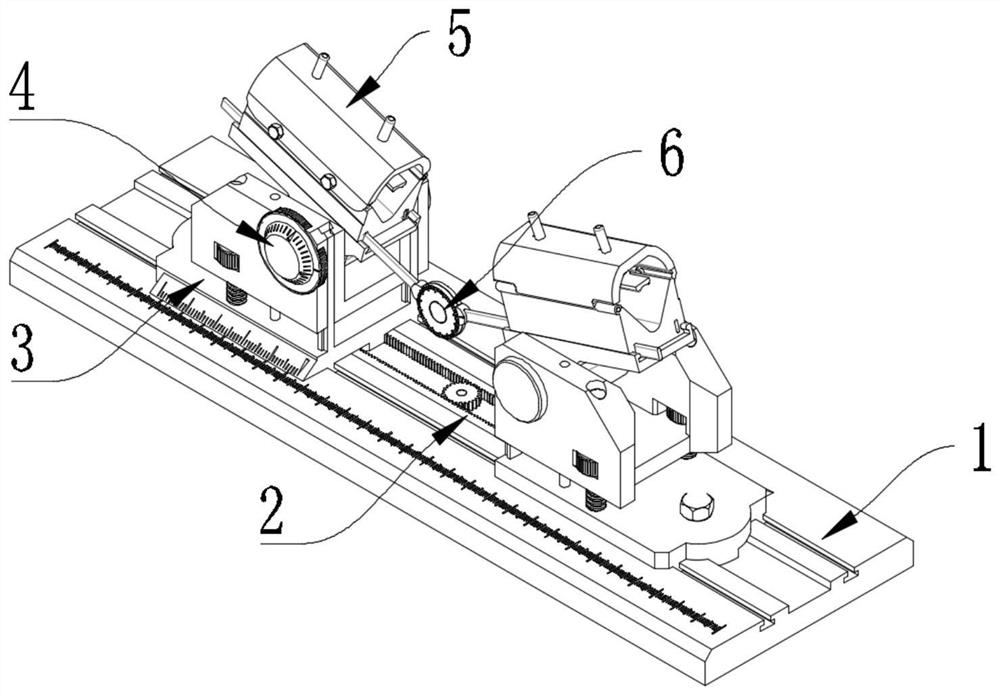

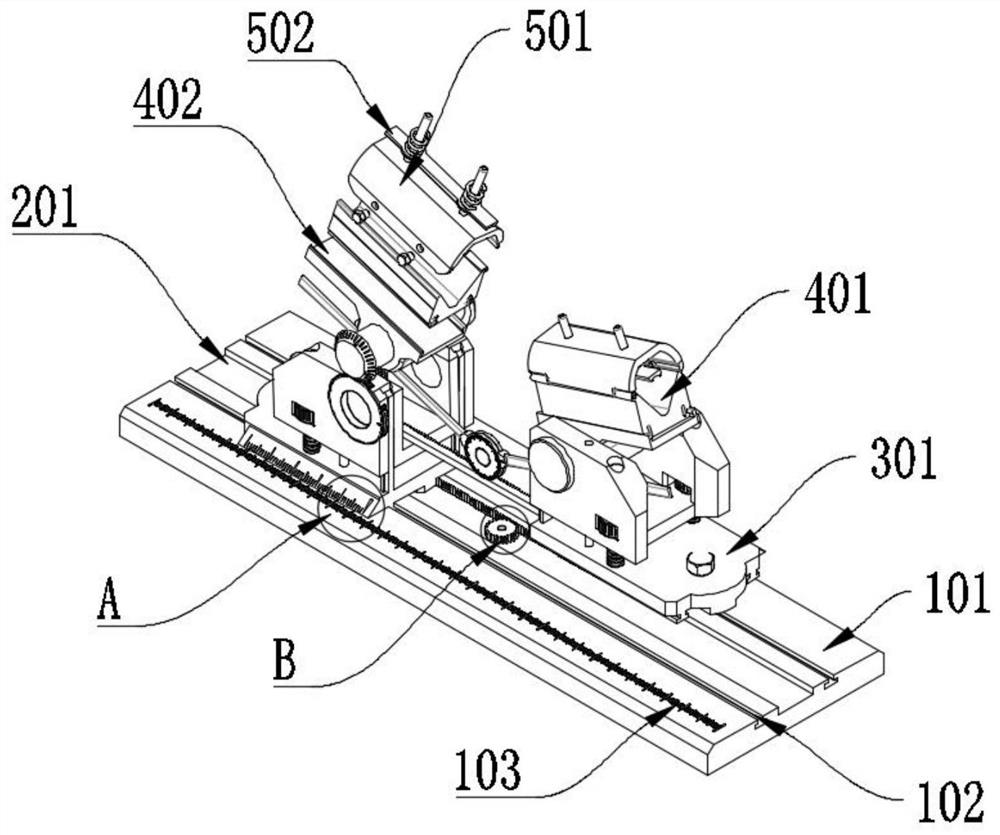

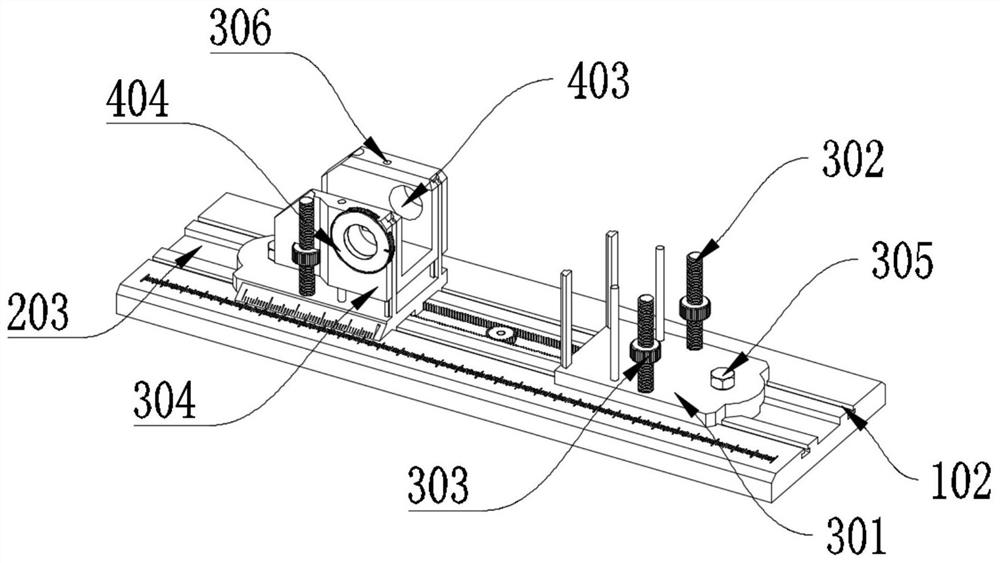

[0036] as attached figure 1 to attach Figure 10Shown:

[0037] The invention provides a steel bar bending strength detection device equipped with an automatic guiding mechanism, which includes a mounting structure 1; a lifting structure 3 is installed on the mounting structure 1 through a sliding connection, and the lifting structure 3 is arranged at two symmetrical places; the lifting structure 3 They are connected by a symmetrical structure 2; a guide structure 4 is hingedly installed on the lifting structure 3, and a clamping structure 5 is installed on the guide structure 4 through a hinged connection; the auxiliary structure 6 is installed in two guides in a sliding manner. Between the structures 4, a sliding fixing screw 305 is installed on the outer side of the integral sliding plate 301 of the lifting structure 3, and the whole sliding fixing screw 305 is fixed by threaded connection, and the overall position of the sliding fixing screw 305 is connected with the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com