Bolt connection

A connecting device and bolt technology, applied in the direction of rod connection, connecting components, cranes, etc., can solve the problem of increasing the force of moving bolts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

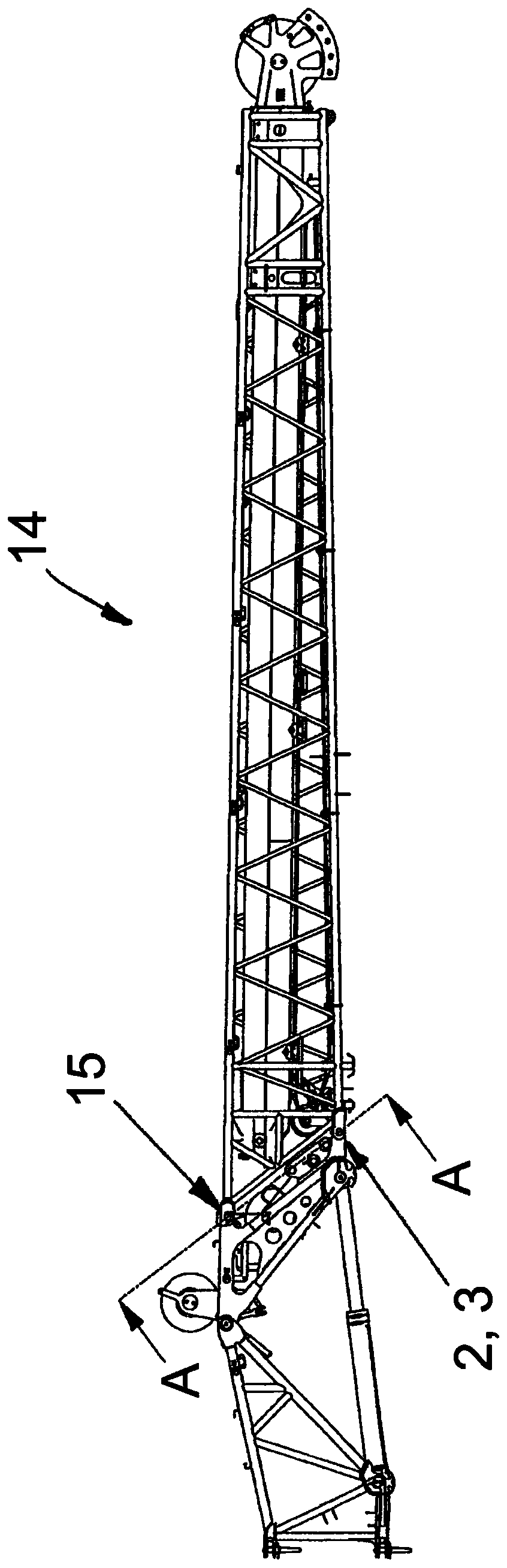

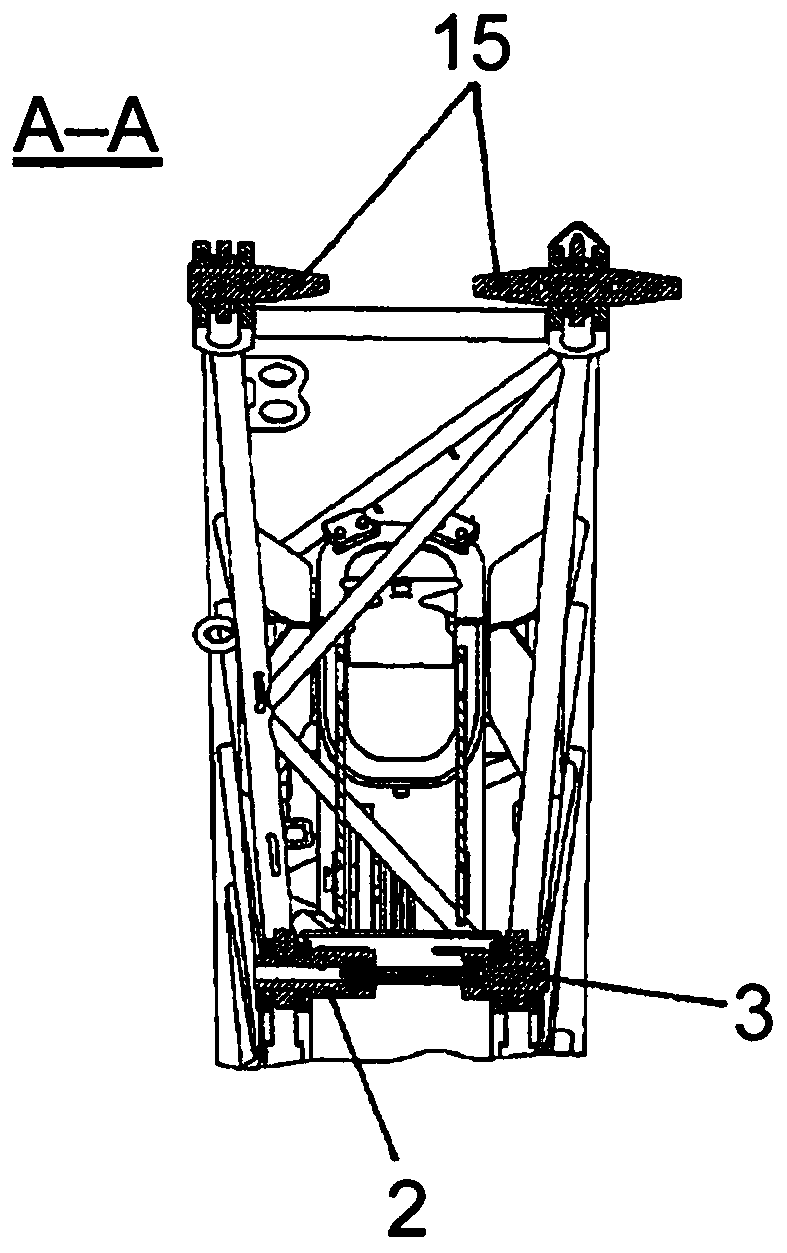

[0028] In order, for example, to be able to operate the telescopic boom of a mobile crane beyond the upper edge of a building, a jib head is often used. Such boom heads are for example made of figure 1 The reference numeral 14 in represents. figure 1 The jib head shown in includes a lattice masthead structure in which its proximal end ( figure 1 ) can be bolted horizontally to a head adapter (not shown in detail), which in turn can be bolted to a telescoping boom of a mobile crane (not shown). The pitch angle of the boom head 14 can be changed relative to the telescoping boom by the hydraulic cylinders of the head adapter.

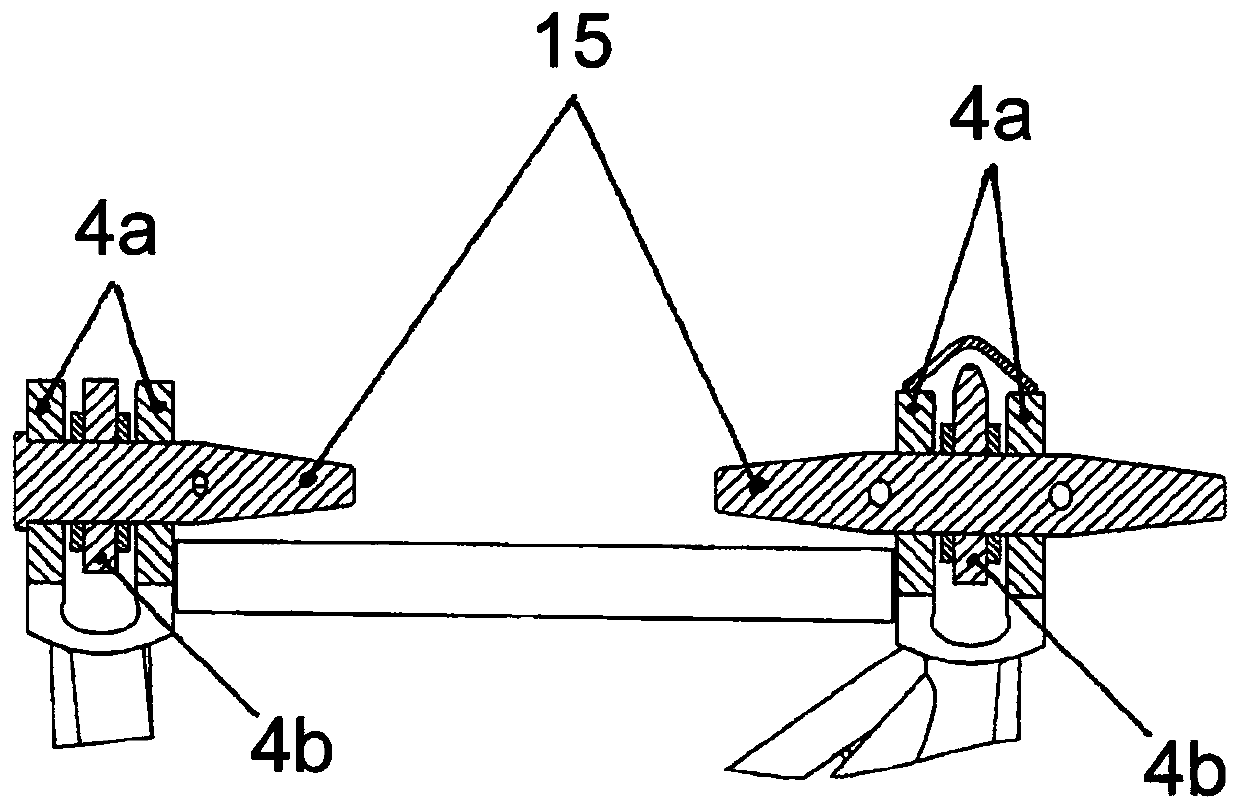

[0029]In order to bolt the lattice masthead to the head adapter and thus to the telescoping jib, the optionally fitted lattice masthead 14 comprises two opposing bolts 2 and 3 according to the invention. bolt connection device. In the example shown, the bolting location above this between the truss mast and the head adapter is bolted by common bolts 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com