Trench depth measuring device and method

A measuring device and ditch depth technology, which is applied in the field of field measurement, can solve the problems of inconvenient measurement of deep ditch and steep slopes, and achieve the effect of improving personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

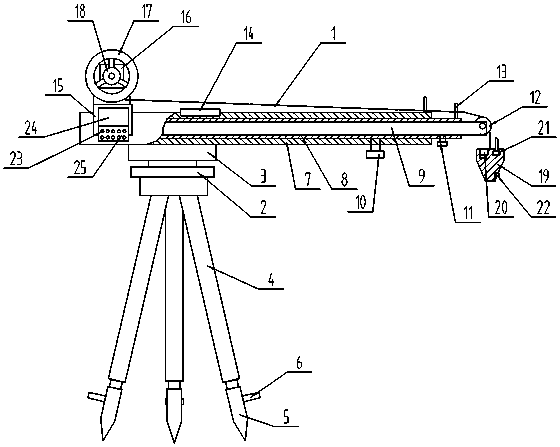

[0033] Referring to Figures 1-2, it is a schematic structural diagram of Embodiment 1 of the present invention, a device for measuring the depth of a trench, including a control unit, and also includes:

[0034] Chassis;

[0035] a support part, the support part is detachably connected to the top of the chassis;

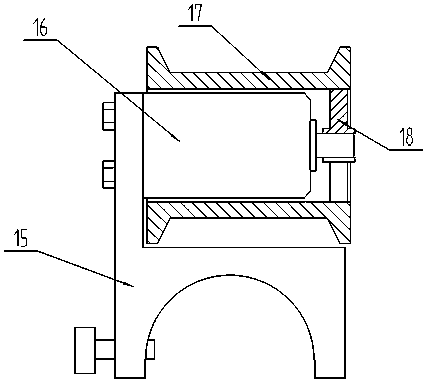

[0036] a winding part, the winding part is detachably connected to one end of the supporting part;

[0037] A measuring line 1, one end of the measuring line 1 is wound on the winding part, and the other end is hung on the other end of the supporting part;

[0038] Hanging and sinking part, the hanging and sinking part is fixed at the other end of the measuring line 1.

[0039] In actual use: erect the supporting part on one side of the ditch through the chassis, so that one end of the supporting part is located above the ditch, and then control the winding part to release the measuring line 1 through the control unit. Under the action of gravity, the measurement ...

Embodiment 2

[0041] On the basis of Embodiment 1, referring to Fig. 1, the difference of this embodiment is that the base frame includes a top seat 2, a turntable 3 and a tripod 4, and the supporting part is detachably connected to the upper surface of the turntable 3, so The lower surface of the turntable 3 is rotatably connected to the upper surface of the top base 2, and the top base 2 is detachably connected to the tripod 4.

[0042] In actual use: first set up the tripod 4 on one side of the ditch, connect the top base 2 to the top of the tripod 4, then connect the support part to the turntable 3, after the support part is deployed, rotate the support part, and the support part passes through the turntable 3 Rotate on the top seat 2, so that one end of the support part moves above the bottom of the ditch.

Embodiment 3

[0044] On the basis of Embodiment 2, referring to FIG. 1 , the difference of this embodiment is that: each leg of the tripod 4 is fixed with a pin 5 , and a pedal 6 is fixed on the pin 5 .

[0045] In actual use: fix the pin 5 on the legs of the tripod 4, then place the tripod 4 on one side of the ditch through the pin 5, and then step on the pedal 6 to insert the pin 5 into the ground to increase the stability of the tripod 4. When the tripod 4 is tilted, it is leveled by adjusting the length of the telescopic legs in the tripod 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com