Quick positioning structure for riveting of thin cooling fins and thin cover plate

A heat dissipation fin and positioning structure technology, applied in the direction of heat exchanger fixation, heat exchange equipment, heat exchanger shell, etc., can solve the problem of time-consuming and laborious, the convex part is easy to come out of the riveting hole, and the thin heat dissipation fin is easy to left and right. Problems such as deflection can be solved to achieve the effect of improving quality and avoiding left and right deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

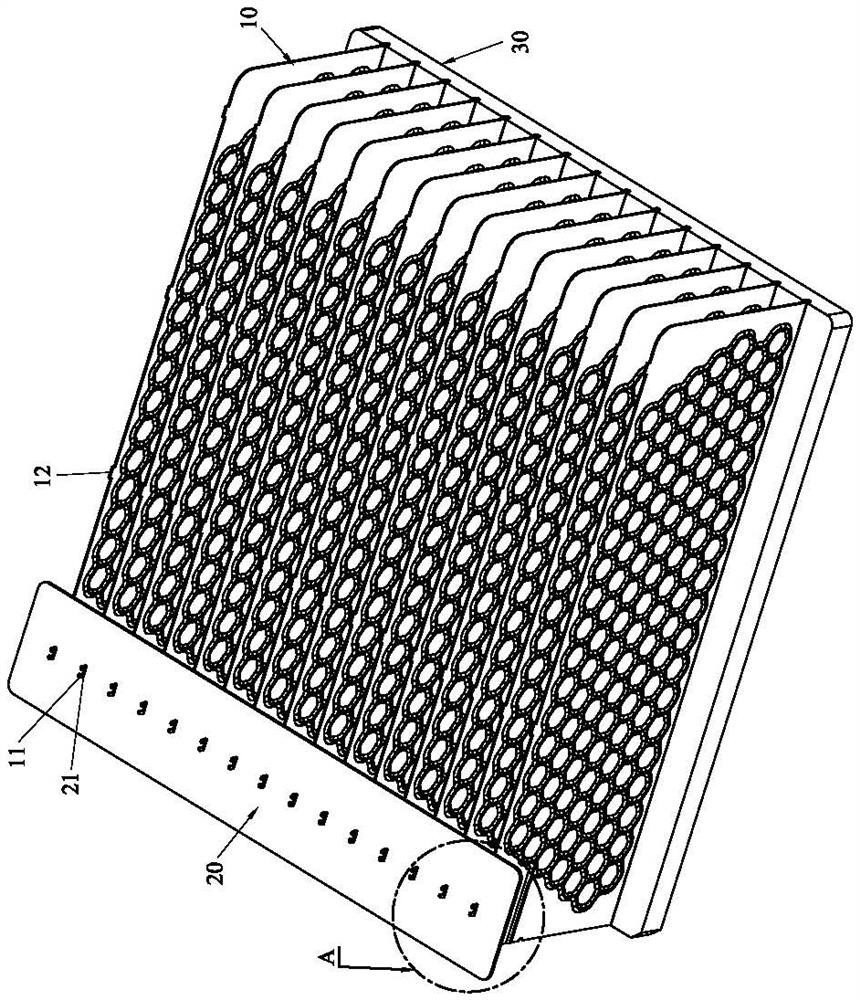

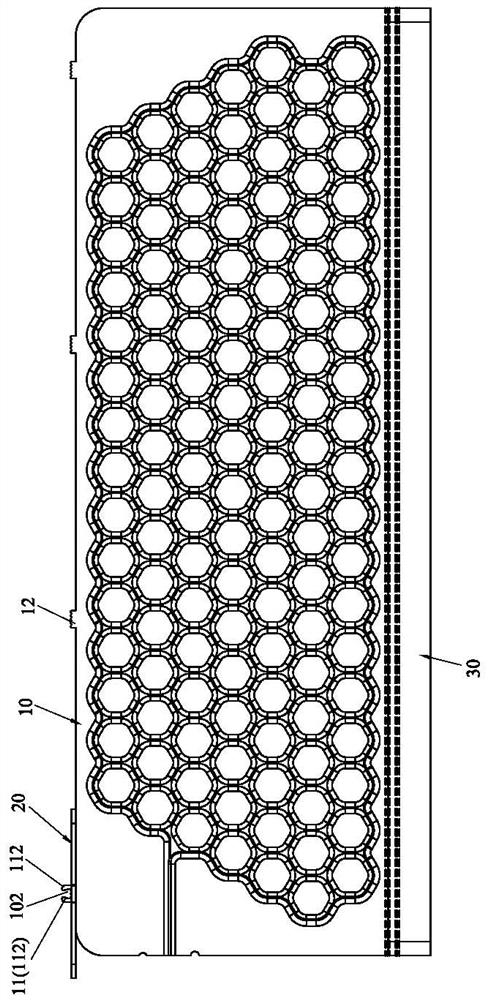

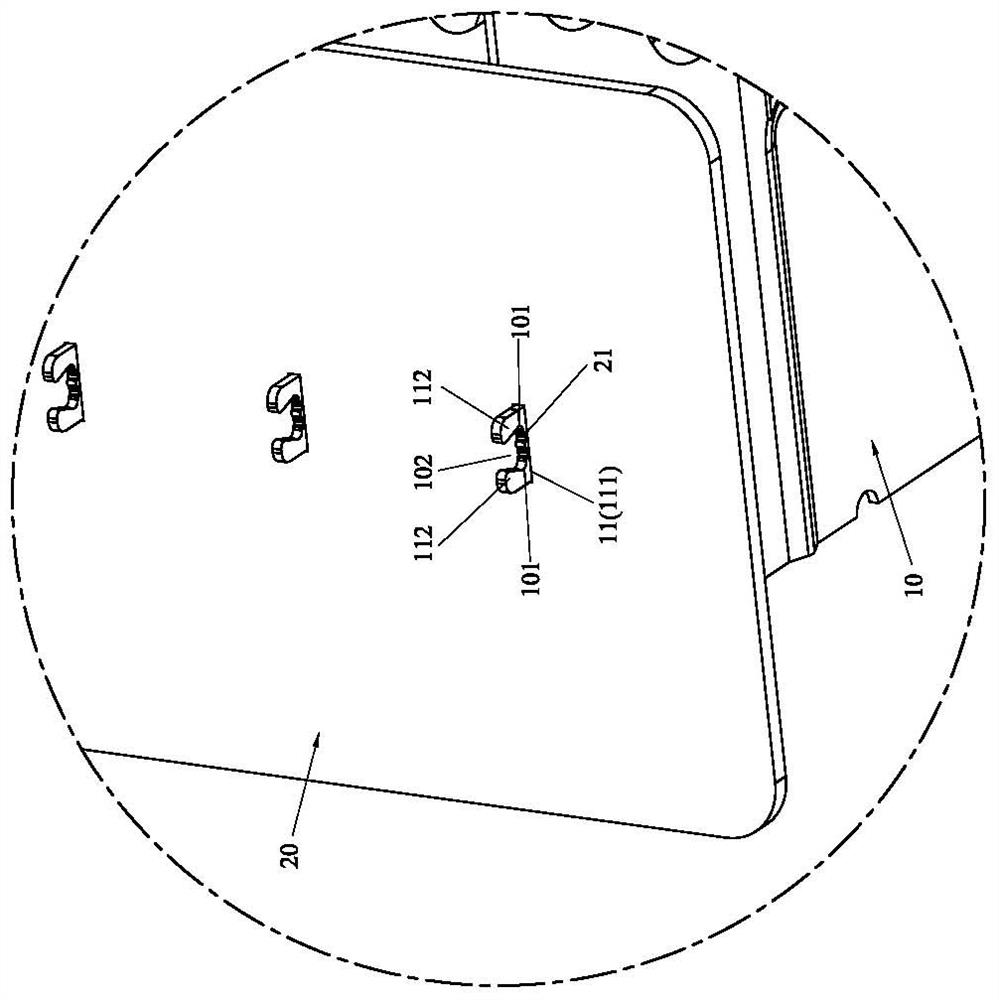

[0037] Please refer to Figure 1 to Figure 9 As shown, it shows the specific structure of the first preferred embodiment of the present invention, including a plurality of thin heat dissipation fins 10 and a positioning plate 20 .

[0038] The plurality of thin heat dissipation fins 10 are vertically arranged, and a positioning protrusion 11 extends from the top of each thin heat dissipation fin 10; a riveting protrusion 12 extends from the top of each thin heat dissipation fin 10, and the riveting protrusion 12 The protruding part 12 is used for riveted and fixed installation of a thin cover plate (not shown in the figure); in this embodiment, the thin heat dissipation fin 10 is an inflatable plate with good heat dissipation performance, and multiple thin heat dissipation fins The fins 10 are vertically arranged side by side at intervals and fixed on a heat dissipation base 30, and the positioning protrusions 11 are located on one side of the thin heat dissipation fins 10, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com