Warmer with mechanical accurate temperature control function

The utility model relates to a heater and a mechanical technology, which is applied in the field of improvement of the heating component mechanism of the heater.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

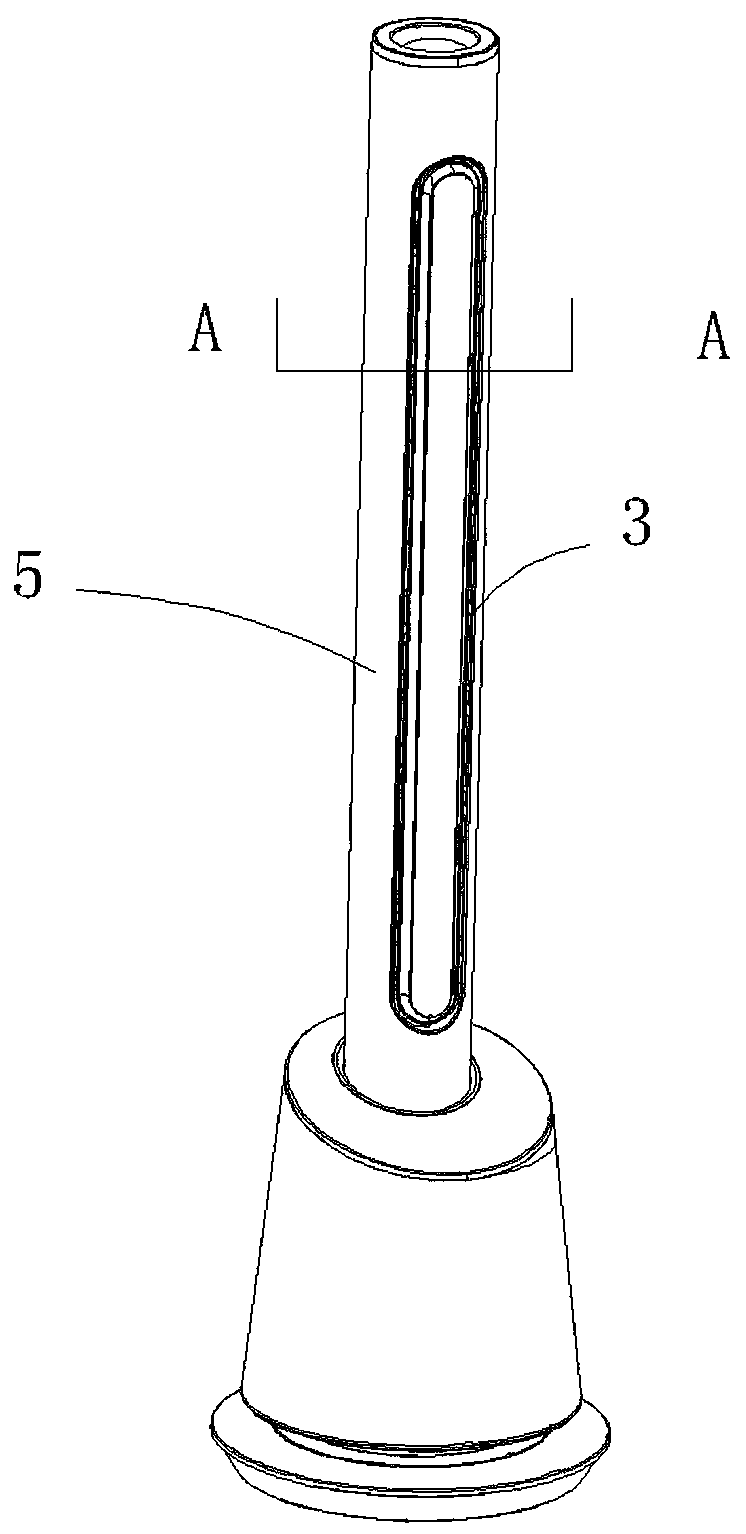

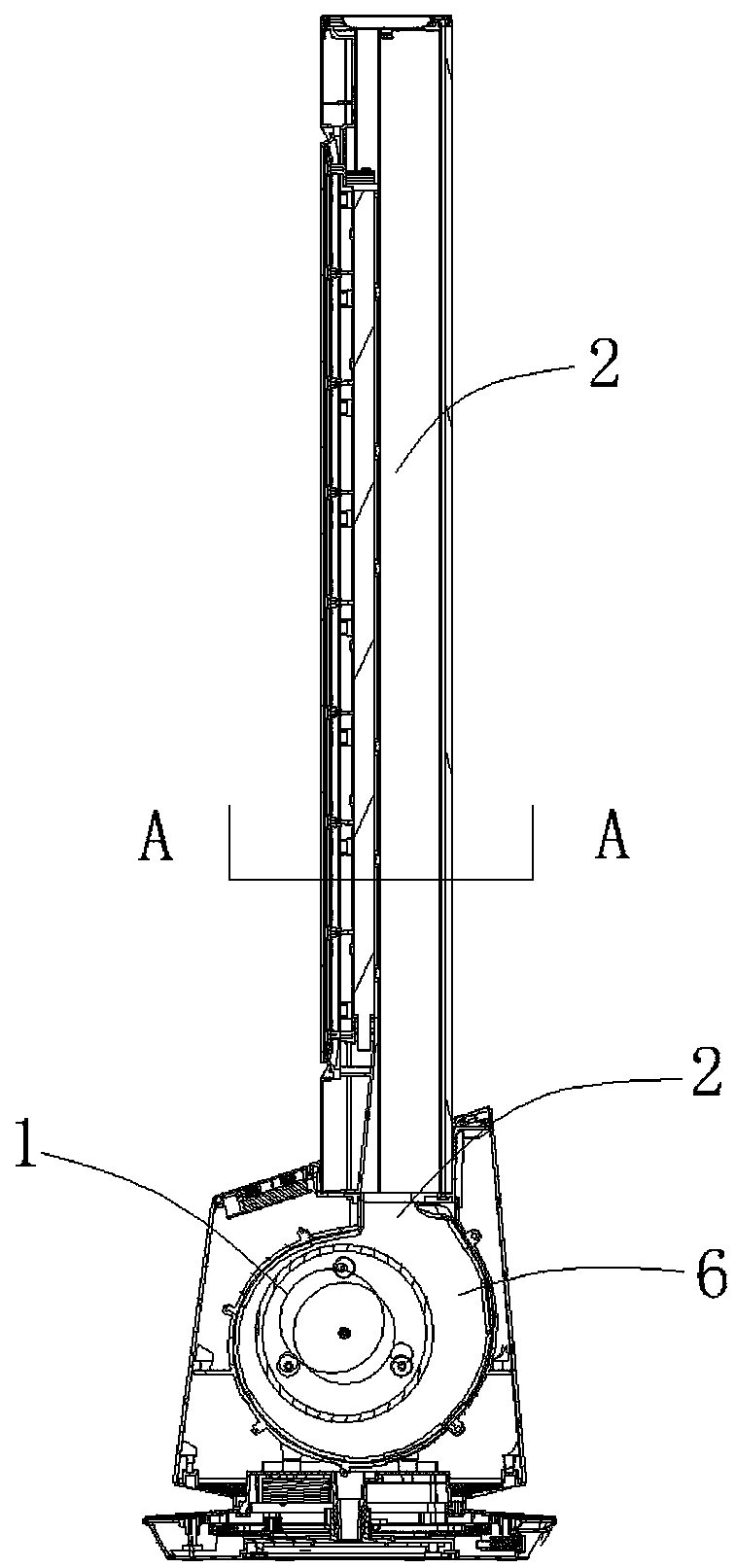

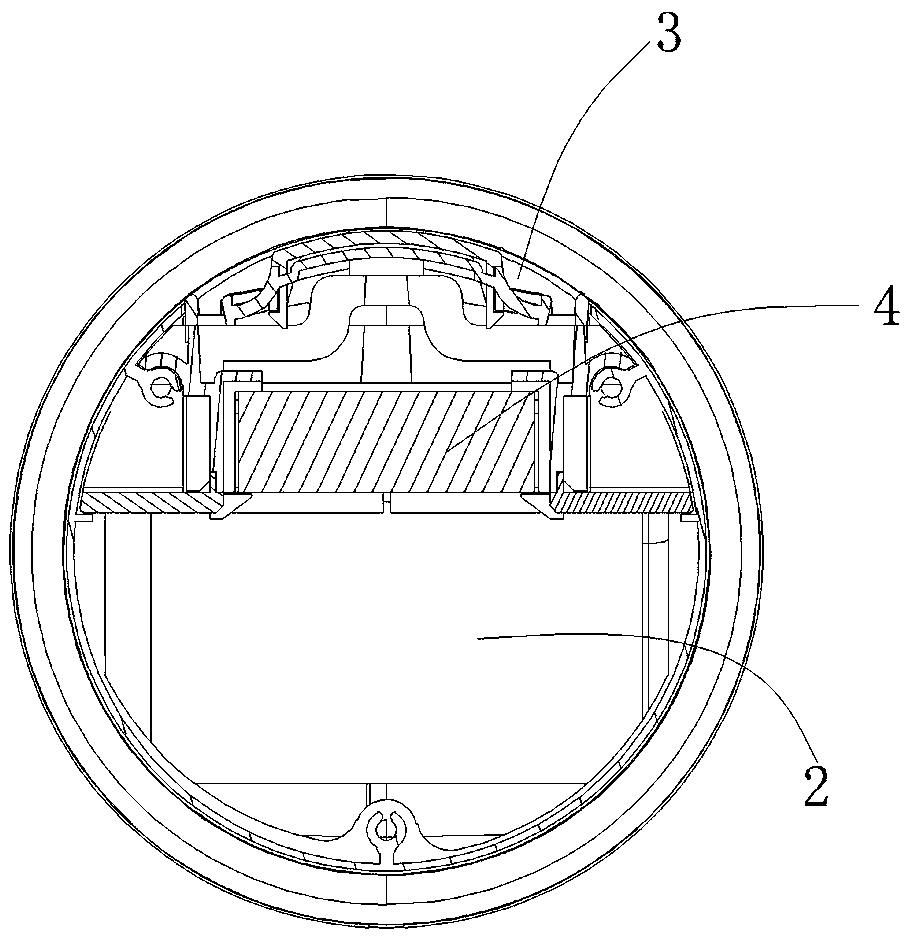

[0027] combined with Figures 1 to 5 , a heater with mechanical precise temperature control function, including a fan 1 and an air chamber 2, the fan 1 is located in the air chamber 2, the front side of the air chamber 2 is provided with an air outlet 3, the air chamber 2 A heating assembly 4 is provided at the front side leading to the air outlet 3, the air outlet 3 is located in front of a bladeless fan column 5 above, the fan 1 is located in the fan chamber 6 below, and the heating assembly 4 is composed of One is composed of several groups of vertically arranged heating grids 7 and a bimetallic group 8 that strings these heating grids 7 together in a horizontal direction. The direction of the bimetallic group 8 is to face the air outlet surface, The heated middle part is bent outwards, and several heat insulating components 9 are provided at the connection between the bimetal sheet group 8 and the heating grid sheet 7 .

[0028] The heat insulation component 9 is a silica...

Embodiment 2

[0031] combined with Figures 4 to 8 , another kind of heater with mechanical precise temperature control function, including a fan 1 and an air chamber 2, the fan 1 is located in the air chamber 2, the front side of the air chamber 2 is provided with an air outlet 3, the air chamber 2 A heating assembly 4 is provided at the front side leading to the air outlet 3, a storage compartment 11 is provided behind the air chamber, and the upper end of the heating assembly 4 is rotatably arranged in the air chamber 2, and the heating assembly 4 rotates Stored in the storage compartment 11 or rotated to the air outlet 3, the heating assembly 4 consists of several groups of vertically arranged heating grids 7 and a bimetallic sheet that strings these heating grids 7 together in a horizontal direction Group 8 is formed, the direction of the bimetal sheet group 8 is to face the air outlet surface, the heated middle part is bent outward, and several heat insulating components 9 are provide...

Embodiment 3

[0035] combined with Figure 4 , attached Figure 5 , attached Figure 6 , attached Figure 9 , there is also a heater with mechanical precise temperature control function, including a fan 1 and an air chamber 2, the fan 1 is located in the air chamber 2, the front side of the air chamber 2 is provided with an air outlet 3, the air chamber 2 A heating assembly 4 is provided at the front side leading to the air outlet 3, and the heating assembly 4 is composed of several groups of vertically arranged heating grid sheets 7 and a pair of horizontally connecting these heating grid sheets 7 together. The metal sheet group 8 is formed, the direction of the bimetal sheet group 8 is to face the air outlet surface, the heated middle part is bent outward, and several heat insulating components 9 are arranged at the connection between the bimetal sheet group 8 and the heating grid sheet.

[0036] The heat insulation component 9 is a silica airgel felt 10, the silica airgel felt 10 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com