Steel mesh engraving component with arcs

A technology of steel mesh and components, which is applied to building components, structural elements, building reinforcements, etc., can solve problems such as affecting the normal use of construction equipment, changing the strength of concrete structures, and blocking the pipelines of cast-in-place concrete delivery pumps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

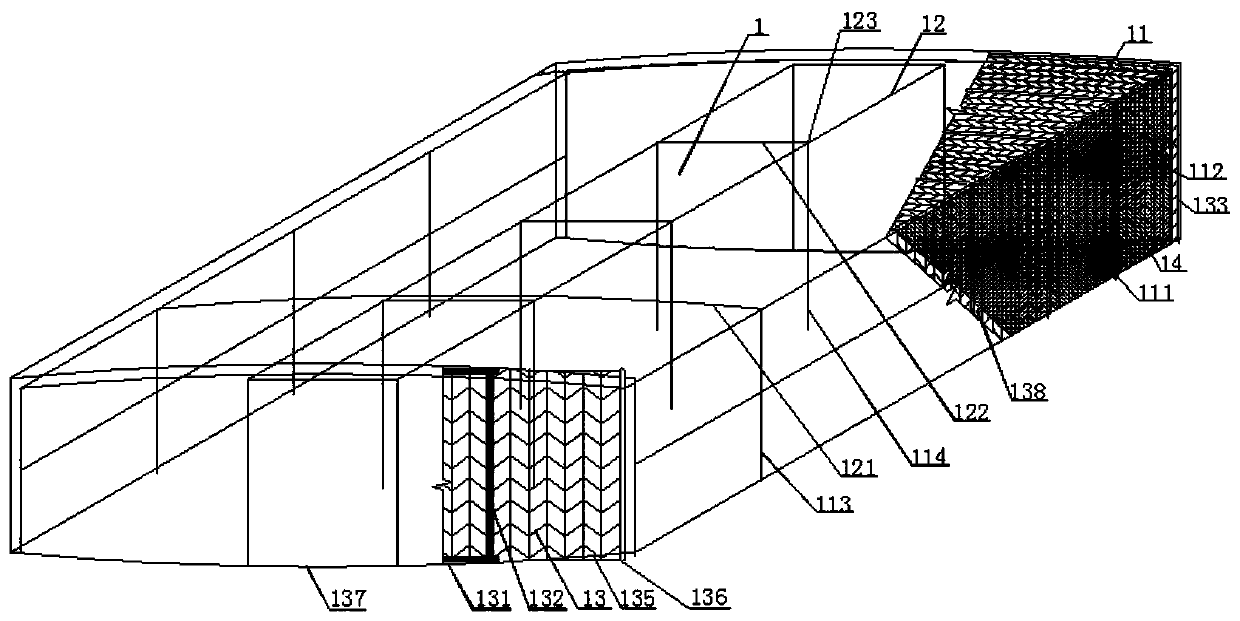

[0017] The present invention will be further described below in conjunction with the drawings.

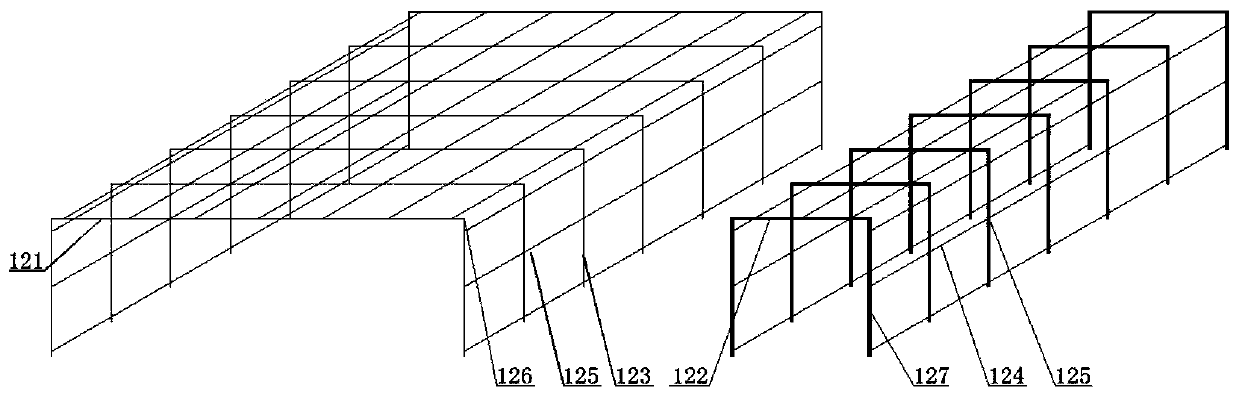

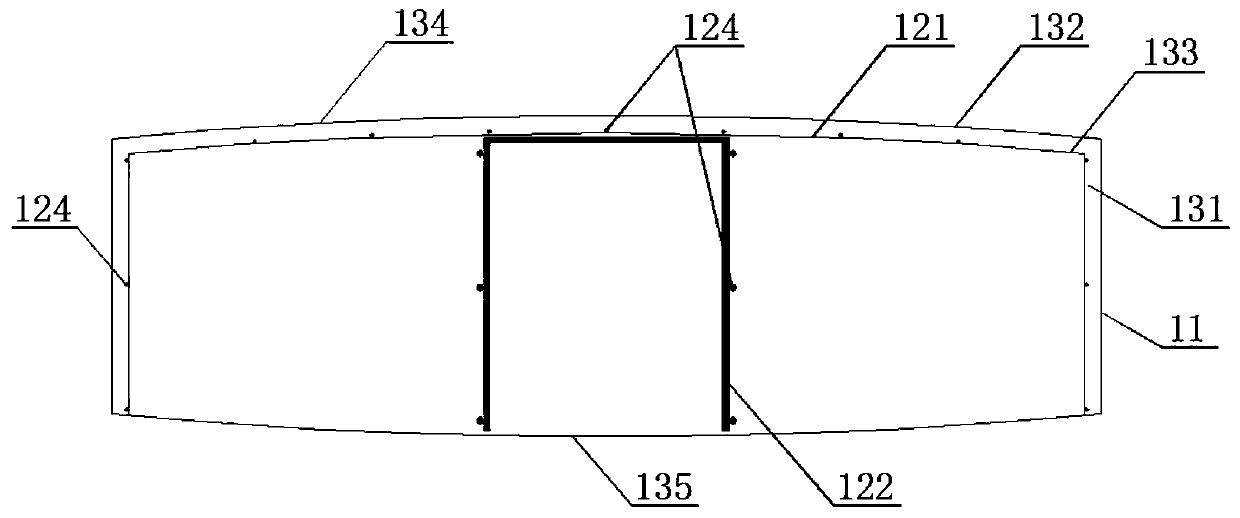

[0018] figure 1 This is an embodiment of an arc-shaped steel mesh skeleton member of the present invention. When the present invention is implemented, according to the functional requirements of the steel mesh skeleton member 1, a ribbed steel mesh 11, a composite laminated support frame 12, and a short plug are first produced. The web 13 and the non-woven fabric 14 are rolled; the ribs of the ribbed steel mesh 11 with the rib 111 and the connecting piece 112 are horizontally pressed according to the required specifications with two knives to control the width of the fold to control the width and two knives to control the height 50mm overlap is reserved at both ends of the ribbed steel mesh; the composite laminated support frame is divided into a wide group 121 to form a width 113 and a narrow group 122 to form a height 114; using coiled steel wire, cold drawn Wire drawing equipment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com