Fabric cutting and synthesizing system

A fabric and cutting device technology, which is applied to the cutting of textile materials, processing of textile material carriers, devices for coating liquid on the surface, etc., can solve the problems of high labor intensity for workers, affecting product quality, and inability to smooth fabrics, etc., to achieve Improve productivity and water spray quality, reduce labor intensity of workers, and overcome the effect of limited water spray range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

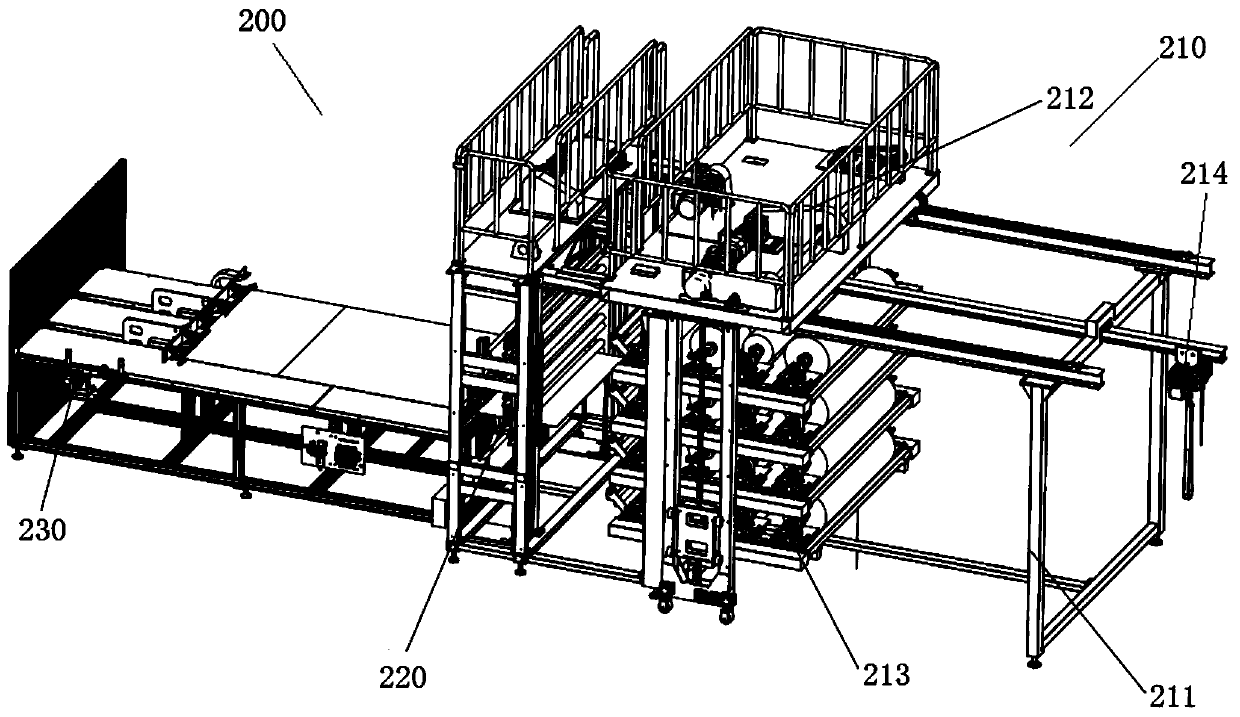

[0054] The fabric cutting and synthesis system includes such as figure 1 The cutting device 200 shown and as Figure 12 Fabric synthesis setup shown.

[0055] The cutting device 200 and the fabric synthesis device are separated, and can be set in different workshops or in the same workshop. In the embodiment, the cutting device 200 is set beside the fabric synthesis device in the same workshop.

[0056] like figure 1 As shown, the cutting device 200 includes a feeding part 210, a cutting part 220, a pulling part 230 and a cutting control part.

[0057] Feeding part 210, cutting part 220, pulling part 230 figure 1 set up in order from left to right.

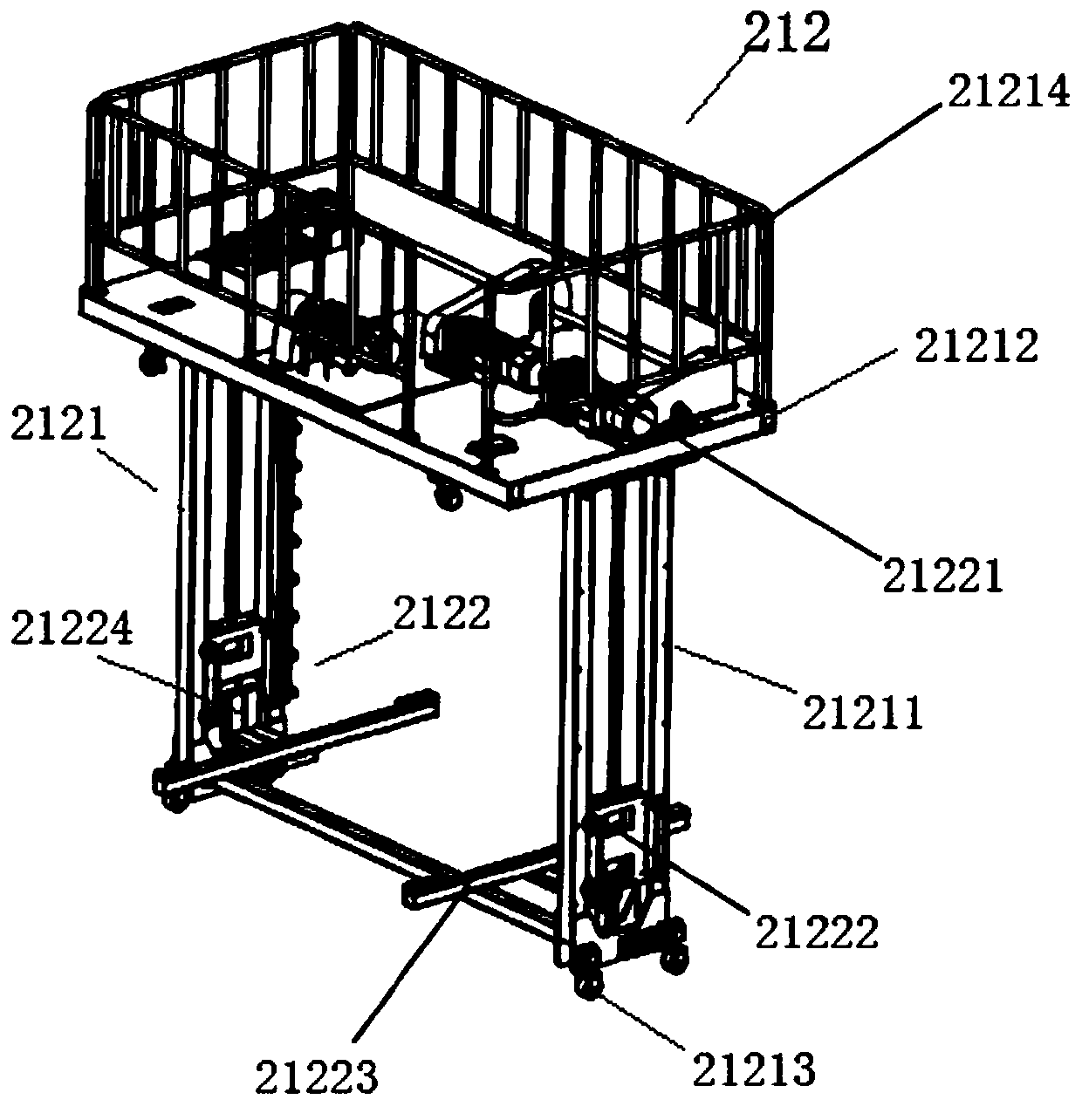

[0058] The feeding part 210 includes a feeding rack 211, a feeding mobile platform 212, a pallet unit 213, and an electric hoist 214.

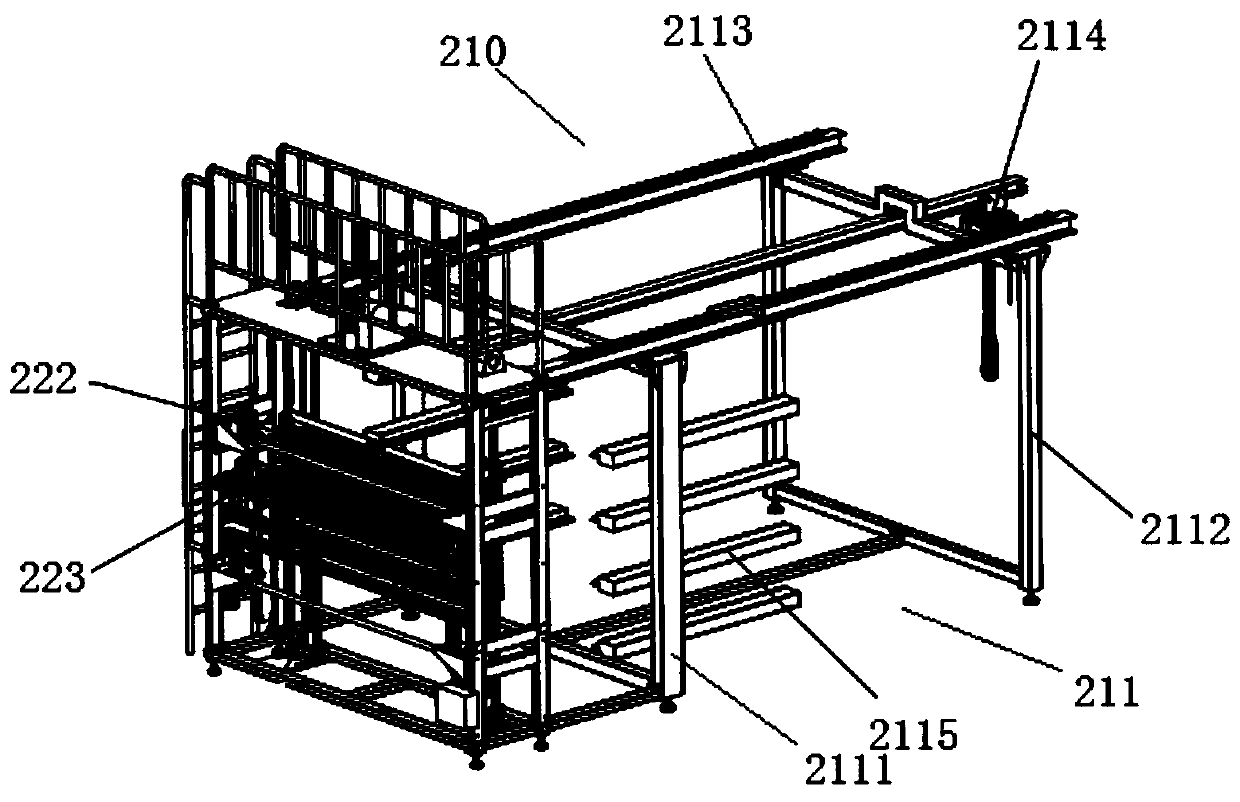

[0059] like figure 2 As shown, the loading rack 211 includes a frame and a plurality of pallet hangers 2115 .

[0060] The frame includes a front frame 2111, a rear frame 2112, two platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com